Why Choose Vanmodel sheet metal?

✔ Real-time progress monitoring order management system to ensure on-time delivery.

✔ ISO 9001 certified, providing dimensional reports and material certificates.

✔ Supports both low minimum order quantities and high-volume customization.

✔ Serves multiple well-known companies across numerous countries worldwide.

✔ One-stop service: from product design, mold design, mold manufacturing to mass production.

✔ Global delivery support (including: air freight, sea freight, land freight, DHL, UPS, etc.).

Product Categories

Automotive Sheet Metal Fabrication

Specializes in precision auto components for body structures, chassis, and lightweight solutions.

Medical Sheet Metal Fabrication

Vanmodel Sheet Metal manufactures medical device enclosures, surgical tools, and cleanroom-compliant cabinets.

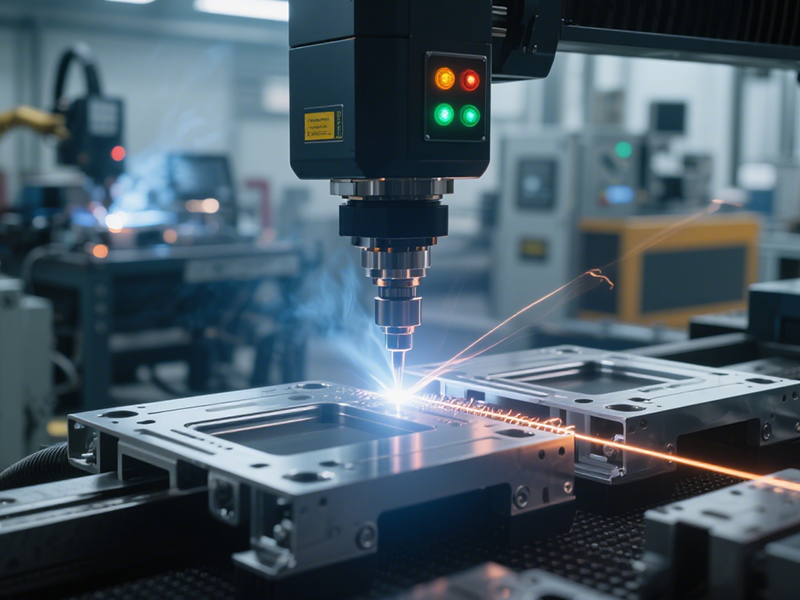

Semiconductor Sheet Metal Fabrication

Vanmodel Sheet Metal creates precision semiconductor parts for wafer handling and equipment housings.

Sheet Metal Enclosure Design

Vanmodel Sheet Metal delivers custom electrical cabinets, server chassis, and protective environmental cases.

Precision Stamping Dies

Vanmodel Sheet Metal produces high-accuracy dies for high-volume microelectronic and auto components.

Other Precision Metal Parts

Vanmodel Sheet Metal supplies specialized tight-tolerance components for aerospace and energy sectors.

Vanmodel Sheet Metal’s One Stop Custom Service

Expertise in Flexible Customization from 1 to 10,000+ Parts

Vanmodel Sheet Metal understands the distinct needs of every product development and production stage. We offer truly flexible custom sheet metal fabrication services, seamlessly supporting the entire workflow from low-volume prototyping to large-scale production.

Whether you need rapid prototyping for design validation or a 50-piece small-batch pilot run, we have no Minimum Order Quantity (MOQ) requirements. Once your design is finalized, our robust production capacity can instantly scale to high-volume manufacturing, ensuring consistent quality, materials, and precision across thousands of parts.

The same commitment to quality and service, for any order size.

DAVE Air deserves respect

Louis Thomas

Governor

FAQ