About

About Us

Welcome to Vanmodel Sheet Metal

We are industry experts in precision sheet metal fabrication, with 15 years of global customer collaboration. Our real-time order tracking system ensures on-time delivery of:

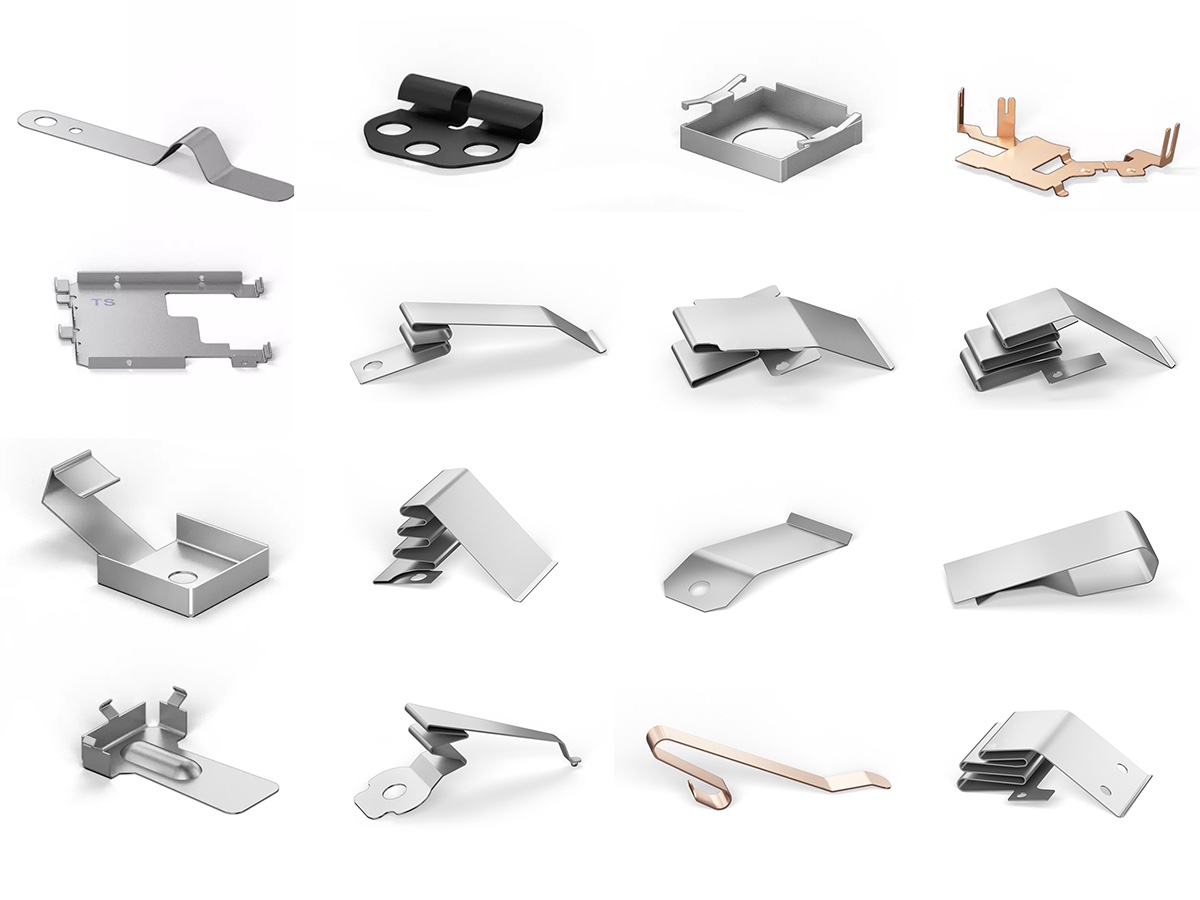

✔ Precision sheet metal parts

✔ Precision metal stamping dies & components

As an ISO 9001-certified manufacturer, we utilize advanced inspection equipment—including VMM (Video Measuring Machine), CMM (Coordinate Measuring Machine), height gauges, and micrometers—to provide dimensional inspection reports for every batch, guaranteeing the quality of your custom precision parts.

We serve leading companies like ASML and Huawei, producing parts with extremely high dimensional and cosmetic requirements. From product design, material selection, precision machining, to surface finishing, Vanmodel Sheet Metal delivers end-to-end manufacturing solutions. We work with 50+ certified metal and plastic materials, catering to industries such as automotive, medical, and semiconductor.

Global logistics support via DHL, FedEx, air freight, and sea shipping ensures efficient delivery worldwide.

1. Our Manufacturing Expertise

✔ High-Speed Precision Stamping – Advanced presses with expertise in multi-stage & progressive die design, specializing in auto parts, electronic connectors, and high-precision components.

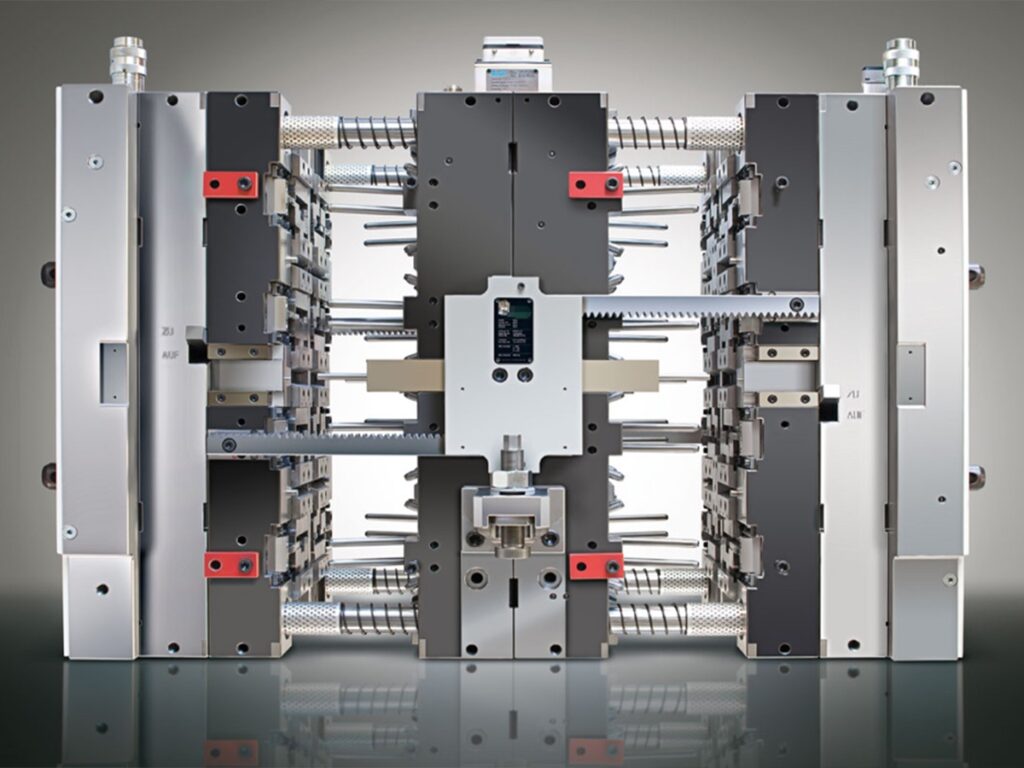

✔ Custom Stamping Die Design & Production – Experienced mold engineers design high-performance, long-life dies (precision progressive dies) to accelerate time-to-market.

✔ Complex Sheet Metal Welding – Mastery of laser, spot, MIG/MAG, and TIG welding, especially for thin-gauge, complex geometries, and critical applications (e.g., medical sterile environments, airtight/watertight seals).

✔ Sheet Metal Fabrication & Forming – Full-service capabilities: laser cutting, CNC bending, shearing, punching, riveting, wire drawing, sandblasting, and die-casting.

✔ Component Integration & Assembly – Turnkey solutions including cleaning, packaging (industry-compliant), and full assembly.

2. Precision Solutions for Key Industries

🔹 Automotive Electronics – Engine brackets, seatbelt components, sensor housings, connector terminals, EV battery parts, interior trim. Focus: tight tolerances, structural strength, high-volume consistency (IATF 16949 compliant).

🔹 Medical Devices – Equipment enclosures, surgical instrument chassis, endoscope parts, sterilization trays, diagnostic device mounts. Focus: biocompatible materials (e.g., 316L stainless steel), ultra-clean processes, sterile packaging (ISO 13485 compliant).

🔹 Semiconductor Equipment – Chamber assemblies, wafer transfer modules, RF shields, sensor mounts, fluid/gas delivery parts. Focus: contamination-free materials (e.g., specially treated aluminum), vacuum compatibility, ESD protection.

🔹 Industrial Enclosures & Chassis – Server racks, network housings, control panels, power distribution units, instrumentation cases. Focus: EMI/RFI shielding, thermal management, IP ratings, modular designs.

🔹 Consumer Electronics – Smartphone/tablet structural frames, charger housings, smart home device casings, speaker grilles, heat sinks. Focus: lightweighting, ultra-thin forming (<0.2mm), aesthetic finishes, cost-effective mass production.

3. Quality Assurance, Meeting Global Standards

Quality is at our core. Our ISO 9001:2015, IATF 16949 (automotive), and ISO 13485 (medical) certifications ensure compliance with industry benchmarks.

- Advanced metrology lab with CMMs, optical comparators, and surface testers for rigorous dimensional validation.

- Real-time material traceability and APQP/PPAP documentation for automotive projects.

4. Our State-of-the-Art Manufacturing Facility

Located in Guangdong, China, our 2,000㎡ modern plant features:

✔ CNC automation: High-speed stamping presses, precision laser cutters, multi-axis CNC press brakes, robotic welding cells (laser/arc).

Expert Team & Specialized Zones

Our facility is segmented into three specialized manufacturing zones: Sheet Metal Fabrication, Precision Stamping and Precision Metal Mold. This strategic division enables us to cater to the diverse production requirements of precision parts with unparalleled expertise and efficiency.

Quality Control

We are committed to exceptional quality at every stage of our operations. Our process begins with careful selection of raw materials and continues through detailed factory acceptance and production. Specialized technicians oversee and document each step, ensuring rigorous standards are met. Before dispatch, we conduct thorough inspections on every product batch to ensure dimensional accuracy, aesthetic integrity, and overall quality.