Präzisionsmetallstanzen

Where Precision Meets Volume

Vanmodel | Your Trusted Partner in Precision Metal Stamping

Vanmodel excels in high-volume precision metal stamping. We produce 50,000 to 100,000+ units annually. Our specialty is miniature components as thin as 0.002″. We serve industries where accuracy cannot be compromised.

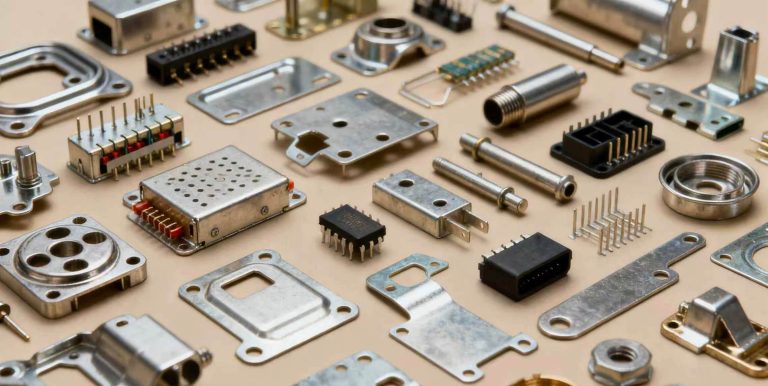

Precision Stamping for Critical Applications

We work with medical, electronics, and automotive clients. They need tight tolerances and minimal variation. We stamp materials from 0.002″ to 0.080″ thick. Pre-plated options are also available.

Materialvielfalt

Zu unseren Kompetenzen gehören:

- Aluminum and stainless steel

- Nickel-plated and pre-galvanized steel

- Cold rolled steel (high and low carbon)

- Brass, phosphor bronze, and copper

Why Tolerances Matter

Tolerances define part accuracy. Even small errors can ruin entire assemblies. This wastes time, materials, and money. Vanmodel combines CAD modeling, tool building, and stamping expertise. We achieve tight tolerances without sacrificing design intent.

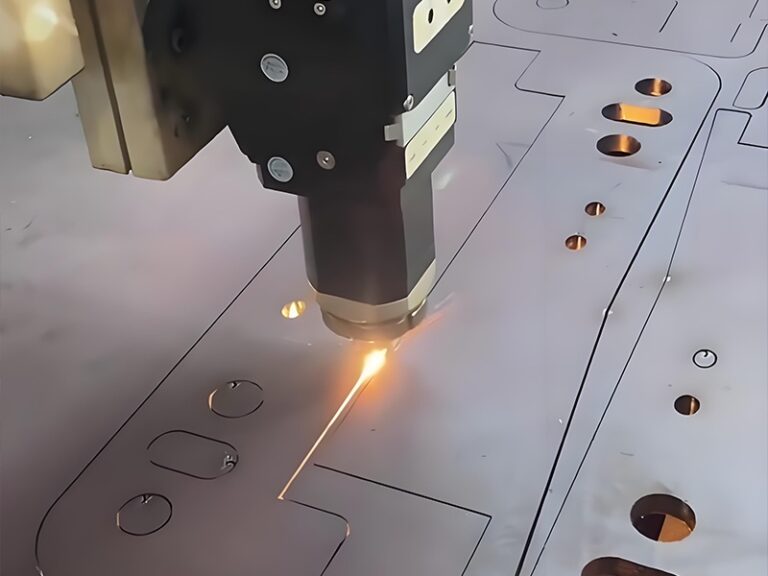

Advanced Stamping Methods

Folgestanzen

A metal strip moves through a press. Each press stroke forms part of the component. This method ensures tight tolerances. Finished parts are automatically separated and collected.

Tiefziehen

This process forms hollow shapes and recesses. It pulls material into a die cavity. We create consistent depths as specified.

Feinschneiden

Ideal for smooth edges and flat surfaces. We handle materials up to 6″ x 6″.

Durchstechen und Schneiden

We create precise holes and cutouts. These operations can be standalone or part of a progressive process.

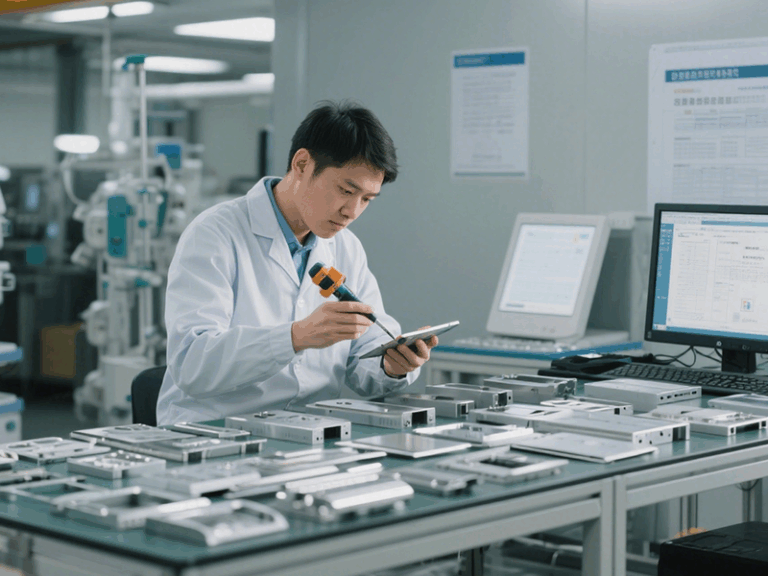

Why Choose Vanmodel

- High Volume: Reliable production of 50,000-100,000+ units yearly

- Micro Precision: Components down to 0.002″ thickness

- Material Range: Broad selection including pre-plated options

- Expert Team: Decades of tool design and manufacturing experience

- Quality Focus: Rigorous checks ensure consistent quality

Start Your Project

Contact us to discuss your needs. Request a quote for your next project. Discover why manufacturers trust Vanmodel for critical components.

Learn more at vanmodel-sheetmetal.com