Automobilindustrie

Wenn 12.000 Rückrufaktionen von Elektrofahrzeugen auf eine einzige fehlerhafte LiDAR-Halterung zurückzuführen sind: Die unsichtbare Herausforderung

In der Elektrofahrzeugindustrie kann ein scheinbar geringfügiger Defekt an einer Blechhalterung eine Kettenreaktion technischer Ausfälle auslösen.

Im Jahr 2023 war ein namhafter Hersteller von Elektrofahrzeugen gezwungen, 12.000 Fahrzeuge zurückzurufen. eine einzelne fehlerhafte LiDAR-HalterungDurch Vibrationen verursachte Materialermüdung führte zu Rissen in der Halterung, wodurch Sensoren falsch ausgerichtet wurden und Fehlalarme bei Kollisionen ausgelöst wurden.

Dies war kein Einzelfall. Da die Automobilindustrie den Übergang von herkömmlichen Verbrennungsmotoren zu Elektrofahrzeugen vollzieht, Tier-1- und Tier-2-Lieferanten Wir stehen vor einer entscheidenden Herausforderung: der Herstellung von Blechbauteilen, die rauen Straßenbedingungen standhalten können.

Als Partner für Blechbearbeitungslösungen für Zulieferer von BMW, Tesla und BYD begegnet Vanmodel diesen Problemen mit folgenden Ansätzen:

Der Vibrationskiller: 3 Ingenieursgeheimnisse

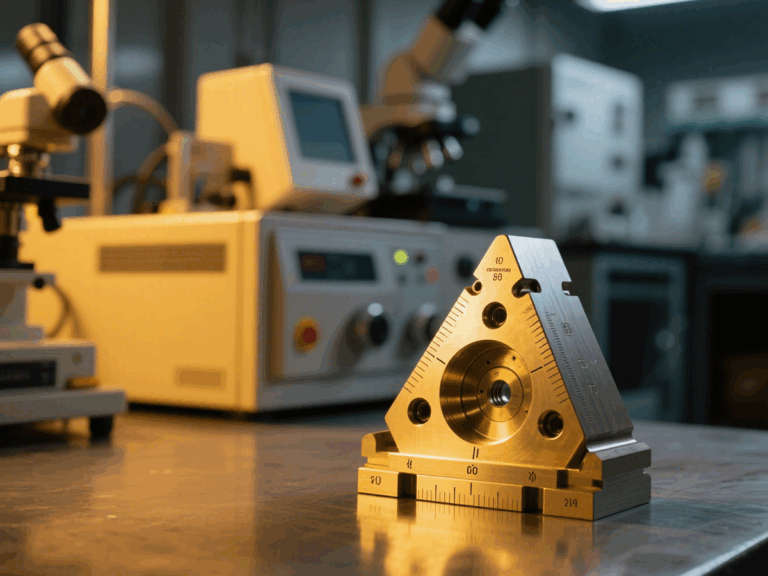

Topologieoptimierte Designs

Bei der Bauteilkonstruktion nutzen wir Altair-Simulationstechnologie um Spannungskonzentrationen in Halterungen und Befestigungen zu identifizieren.

Durch die Vorhersage des Schwingungsverhaltens mittels Finite-Elemente-Modellierung, unser neu gestaltete Bremssensorhalterung hält nun stand 20G Vibration (Erhöhung von 8G).

Diese Methodik ermöglicht es uns, proaktiv potenzielle Schwachstellen zu identifizieren, die bei traditionellen Konstruktionsprozessen übersehen würden.

Ermüdungsbeständige Materialien

Die Materialauswahl ist entscheidend für die Beständigkeit gegen Vibrationsermüdung. Wir verwenden:

- Aluminiumlegierung 6061-T6Angebote 35% höhere Dauerfestigkeit als Standard-6061-Aluminium

- Präzisionsstanzen: Erreicht Toleranz ±0,05 mm auf AMADA-Servopressen, Vermeidung von Mikrorissen

- Hochfester StahlHRC 45 bietet überlegene strukturelle Unterstützung

Die Eigenfrequenz und die Schwingungsformen von Metallkonstruktionen hängen von ihrer Masse und Steifigkeit ab, weshalb eine geeignete Materialauswahl unerlässlich ist.

Dämpfungsintegration

- Lasergeschnittene Elastomerschlitze: Schädliche Resonanzen absorbieren und so die Vibrationsübertragung auf die Sensoren reduzieren

- Elektrisch isolierte Halterungen: Vermeidung von elektromagnetischen Störungen in ADAS-Gehäusen

Durch die Anwendung geeigneter Randbedingungen können wir kritische Bereiche isolieren und Testfrequenzen auswählen, um die gewünschten charakteristischen Moden anzuregen.

Geschwindigkeitsvorteil für EV-Startups

Im wettbewerbsintensiven Markt für Elektrofahrzeuge, Die Markteinführungszeit korreliert direkt mit dem Marktanteil.Wir unterstützen unsere Kunden dabei, die Produktentwicklung zu beschleunigen, durch:

- 15-tägiger Werkzeug- und Formenbau: Folgeverbundwerkzeuge für die Serienfertigung

- Vom Prototyp zur ProduktionDie gleichen AMADA RG-100 Pressgriffe 5-teilige Muster und Chargen von 50.000 Einheiten

- Oberflächenbehandlung: KTL-Beschichtung, Zink-Nickel-Beschichtung zum Korrosionsschutz

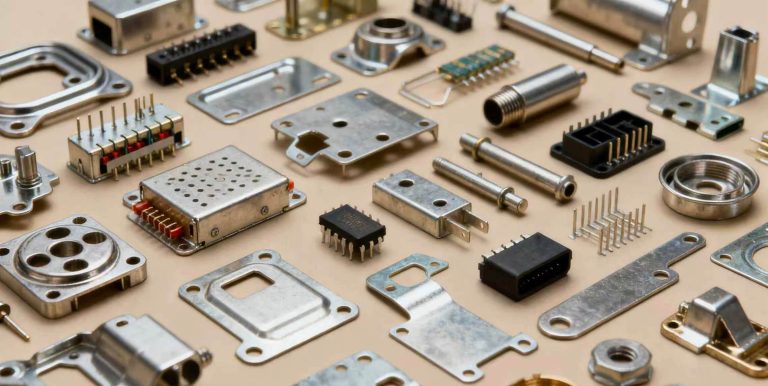

Fähigkeiten in Automobilqualität

Unsere Kompetenzen erfüllen die strengsten Automobilstandards:

- Toleranz: ±0,1 mm für Stanzteile

- Materialien: Hochfester Stahl HRC 45, Al 6061-T6, Kupfer-Nickel-EMI-Abschirmmaterialien

- Einhaltung: IATF 16949-bereite Prozesse

Vanmodel Blechsensorhalterungen hat die 1000-Stunden-Salzsprüh- und Vibrationstests beim ersten Versuch bestanden—Kunden sparen $250.000 an Validierungsnacharbeitskosten.

Abschluss

Im Bereich der Elektrofahrzeuge und des autonomen Fahrens muss jede Komponente zuverlässig sein. Schwingungsermüdung ist keine nachträgliche Überlegung, sondern eine Herausforderung, die bereits in der Entwurfsphase angegangen werden muss.

Durch die Kombination Topologieoptimierung, sorgfältig ausgewählte Materialien, Und innovative DämpfungstechnologienWir stellen sicher, dass die LiDAR-Halterungen und andere kritische Komponenten auch unter anspruchsvollsten Straßenbedingungen ihre Integrität und Funktionalität beibehalten.

Vanmodel Blechbearbeitung – Präzisionsblechlösungen für die Automobilindustrie

Zulieferer von BMW, Tesla und BYD

Stoppen Sie Vibrationsausfälle jetzt

Fordern Sie einen kostenlosen Schwingungssimulationsbericht für Ihr Design an