Kundenspezifisches Metallstanzen für höchste Präzision: Die Herausforderungen beim Stanzen von Metallteilen für Elektrofahrzeuge meistern

Mit der rasanten Entwicklung der Elektromobilitätsbranche beeinflussen Qualität und Präzision der Metallbauteile von Elektrofahrzeugen unmittelbar Leistung, Sicherheit und Reichweite des gesamten Fahrzeugs. Die Stanztechnik für diese Bauteile steht jedoch vor zahlreichen Herausforderungen, wie komplexen Materialeigenschaften, strengen Präzisionsanforderungen und unzureichender Stabilität in der Serienfertigung. Um diese Schwierigkeiten zu bewältigen, haben wir uns intensiv mit dem Bereich der Präzisionsmetallstanzung auseinandergesetzt. Dank unserer langjährigen Erfahrung in der Metallstanzfertigung bieten wir zielgerichtete, kundenspezifische Lösungen an. Die kundenspezifische Metallstanzung für hochpräzise Anwendungen hat sich dabei zu unserem Kernkompetenzfeld entwickelt, um den Anforderungen der Elektromobilität gerecht zu werden und der Branche neue Impulse zu verleihen.

Zentrale Herausforderungen beim Stanzen von Metallteilen für Elektrofahrzeuge und die Bedeutung des Präzisionsstanzens

Die Metallteile von Elektrofahrzeugen umfassen verschiedene Komponenten wie Batteriegehäuse, Motorabdeckungen und Karosseriestrukturteile. Diese Bauteile stellen extrem hohe Anforderungen an den Stanzprozess. Zum einen neigen hochfester Stahl, Aluminiumlegierungen und andere in Elektrofahrzeugen verwendete Werkstoffe während des Stanzprozesses zu Rückfederung, Rissbildung und anderen Problemen. Diese lassen sich mit herkömmlichen Stanzverfahren nur schwer präzise kontrollieren. Zum anderen weisen die Metallteile von Elektrofahrzeugen eine extrem geringe Toleranz gegenüber Abweichungen in Maßgenauigkeit und Oberflächenbeschaffenheit auf. Selbst Fehler im Mikrometerbereich können zum Ausfall der Bauteilmontage und damit zum Ausfall des gesamten Fahrzeugs führen.

Präzisionsstanzen: Gezielte Lösungen

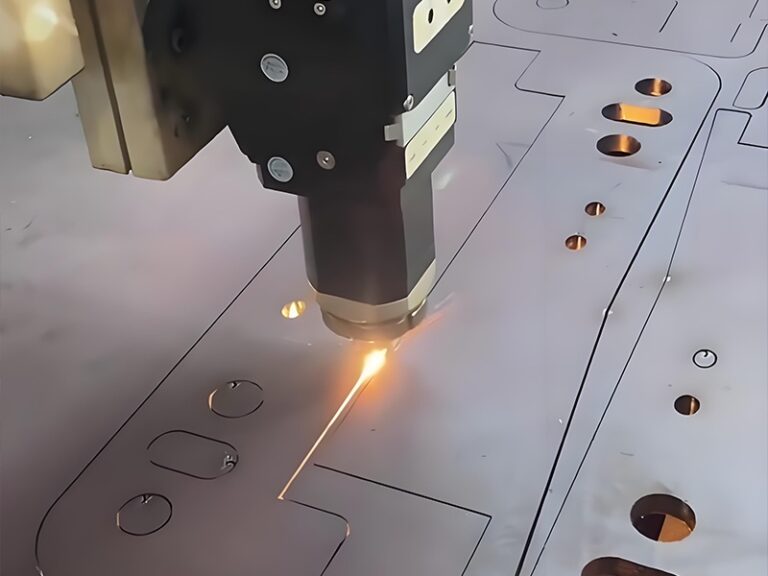

Als Kernstück der hochpräzisen Stanztechnologie löst das Präzisionsstanzen diese Herausforderungen effektiv. Durch die Optimierung des Stanzwerkzeugdesigns, die präzise Steuerung von Stanzdruck und -geschwindigkeit sowie den Einsatz fortschrittlicher Prüftechnik gewährleistet es zuverlässige Ergebnisse bei der Fertigung von Metallteilen für Elektrofahrzeuge. Beim Stanzen von Batteriegehäusen werden Maßtoleranzen innerhalb von ±0,02 mm und eine Oberflächenrauheit unter Ra 0,8 eingehalten, wodurch die Anforderungen an Dichtung und Festigkeit vollständig erfüllt werden. Zudem wird die Stabilität der Serienfertigung sichergestellt und durch Prozessschwankungen bedingte Qualitätsschwankungen vermieden – ein entscheidender Faktor für die Großserienfertigung.

Vorteile der Bearbeitung komplexer Teile

Die Präzisions-Metallstanztechnik eignet sich hervorragend für die Bearbeitung komplexer Strukturbauteile. Sie ermöglicht die einstufige Formgebung von Stanzteilen, wie beispielsweise Motordeckeln mit mehreren Bohrungen und Sonderformen, wodurch aufwendige Nachbearbeitungen entfallen. Dies steigert nicht nur die Produktionseffizienz, sondern reduziert auch Präzisionsverluste während der Bearbeitung. Die so gefertigten hochpräzisen Motordeckel gewährleisten eine optimale Abstimmung mit Motorrotor und -stator, wodurch Geräusche und Energieverluste im Betrieb reduziert und indirekt die Reichweite von Elektrofahrzeugen erhöht wird.

Kundenspezifische Metallstanzung für hochpräzise Anwendungen: Maßgeschneiderte Lösungen für die Bedürfnisse von Elektrofahrzeugen

Unterschiedliche Marken und Modelle von Elektrofahrzeugen stellen spezifische Anforderungen an die Konstruktion und Leistung ihrer Metallbauteile. Standardisierte Stanzlösungen können diesen vielfältigen Anforderungen nicht gerecht werden. Daher ist die hochpräzise, kundenspezifische Metallstanzung eine Schlüssellösung für die Herausforderungen bei der Fertigung von Elektrofahrzeug-Metallbauteilen. Wir entwickeln maßgeschneiderte, hochpräzise Stanzlösungen, die exakt auf die Bedürfnisse unserer Kunden abgestimmt sind.

Kundenspezifische Bedarfsabstimmung

In der frühen Phase der Kundenanpassung führen wir intensive Gespräche mit unseren Kunden, um die Anwendungsszenarien, Leistungskennzahlen, die Materialauswahl und spezielle Anforderungen an die Metallteile für Elektrofahrzeuge zu verstehen – beispielsweise die Leichtbauweise des Batteriegehäuses oder die Stoßfestigkeit von Karosserieteilen. Unser Ingenieurteam kombiniert hochpräzise Stanztechnik, um exklusive Fertigungsprozesse zu entwickeln. So wählten wir beispielsweise für einen Kunden, der ultradünne und hochfeste Stanzteile für das Batteriegehäuse benötigte, eine neue, hochfeste Aluminiumlegierung und kombinierten diese mit einem speziellen Stanzverfahren. Dadurch konnte die Dicke des Batteriegehäuses um 201 TP3T reduziert und gleichzeitig die Druckfestigkeit um 151 TP3T erhöht werden – eine optimale Kombination aus geringem Gewicht und hoher Festigkeit.

Präzisionskontrolle im gesamten Prozess

Die Lösung für kundenspezifisches Metallstanzen für hochpräzise Anwendungen legt Wert auf die präzise Steuerung des gesamten Prozesses. So wird beispielsweise in feuchten Umgebungen korrosionsbeständiges 304-Blech verwendet, während in Bereichen mit hohen Leichtbauanforderungen 6061-Blech bevorzugt wird. Für die Werkzeugkonstruktion nutzen wir eine integrierte CAD/CAM/CAE-Software. Der Stanzprozess wird mittels Finite-Elemente-Analyse simuliert, um mögliche Probleme frühzeitig zu erkennen und zu optimieren. Dies gewährleistet die Präzision und Lebensdauer des Werkzeugs. Parallel dazu wird im Produktionsprozess IoT-Technologie eingesetzt, um die Betriebsparameter der Stanzanlage in Echtzeit zu erfassen und zu analysieren. Sobald ein Parameter den voreingestellten Bereich verlässt, alarmiert das System und passt die Anlage automatisch an. Dadurch wird sichergestellt, dass jedes Produkt aus kundenspezifischem Metallstanzen für hochpräzise Anwendungen den Präzisionsanforderungen entspricht.

Schnelle Reaktionsfähigkeit und Flexibilität

Darüber hinaus bietet die kundenspezifische Metallstanzung für hochpräzise Anwendungen ein hohes Maß an Flexibilität. Sie ermöglicht eine schnelle Reaktion auf Designänderungen seitens der Kunden. Angesichts der rasanten technologischen Weiterentwicklung von Elektrofahrzeugen kann das Design von EV-Metallteilen entsprechend den technologischen Neuerungen angepasst werden. Dank eines ausgereiften Fertigungssystems für Metallstanzung und unserer technischen Kompetenz in diesem Bereich können wir Werkzeugmodifikationen und Prozessanpassungen in kürzester Zeit effizient durchführen. So stellen wir sicher, dass die neuen Produkte unserer Kunden zeitnah in Serie gefertigt werden können, um Marktchancen optimal zu nutzen.

Vollständige Unterstützung der industriellen Wertschöpfungskette: Komplettservice von Präzisions-Metallstanzteilen bis hin zur Präzisions-Metallbearbeitung

Um unsere Kunden im Bereich der Elektrofahrzeuge optimal zu bedienen, konzentrieren wir uns nicht nur auf Kernprozesse wie hochpräzises Stanzen und kundenspezifisches Stanzen, sondern bauen auch ein umfassendes System für die gesamte Wertschöpfungskette auf – von der Produktion präzisionsgestanzter Teile bis hin zur präzisen Metallbearbeitung. Wir bieten unseren Kunden Komplettlösungen aus einer Hand, senken ihre Kosten im Lieferkettenmanagement und steigern die Effizienz der Zusammenarbeit.

Präzisionsstanzfertigung: Qualität und flexible Lieferung

In der Fertigung von Präzisions-Metallstanzteilen kontrollieren wir die Qualität der Rohstoffe streng. Wir pflegen langjährige Kooperationen mit renommierten in- und ausländischen Zulieferern von Präzisionsmetallen. Dadurch stellen wir sicher, dass die verwendeten hochfesten Stähle, Aluminiumlegierungen und anderen Werkstoffe internationalen Standards entsprechen. Darüber hinaus verfügen wir über mehrere moderne Fertigungslinien für Metallstanzteile. Wir können Präzisions-Metallstanzteile in großen Stückzahlen produzieren und so die unterschiedlichen Anforderungen unserer Kunden erfüllen. Ob Kleinserien kundenspezifischer Präzisions-Metallstanzteile oder Großserien standardisierter Produkte – wir garantieren Ihnen zuverlässige Lieferzeiten und höchste Produktqualität.

Präzisionsmetallbearbeitung: Professionelle Bearbeitung & Anpassung

Im Bereich der Präzisionsmetallbearbeitung verfügen wir über professionelle Bearbeitungsanlagen und qualifizierte Fachkräfte. Wir führen an Präzisionsmetallstanzteilen nachfolgende Schweiß-, Biege-, Oberflächenbehandlungs- und weitere Bearbeitungsschritte durch. Beispielsweise verschweißen wir bei Produkten wie Karosseriestrukturteilen, die eine mehrkomponentige Montage erfordern, mehrere Präzisionsmetallstanzteile mittels hochpräziser Schweißtechnik zu einem Ganzen. Die Schweißgenauigkeit wird auf ±0,05 mm begrenzt, um die Stabilität und Sicherheit der Karosseriestruktur zu gewährleisten. Im Bereich der Oberflächenbehandlung bieten wir verschiedene Verfahren wie Verchromen, Verzinken und Lackieren an. Dies verbessert nicht nur die Korrosionsbeständigkeit der Präzisionsmetallstanzteile, sondern ermöglicht es uns auch, individuelle Kundenwünsche hinsichtlich des Produktbildes zu erfüllen.

Vollständige Qualitätsprüfung: Systematische Qualitätsgarantie

Gleichzeitig legen wir großen Wert auf die Qualitätskontrolle während des gesamten Präzisionsmetallbearbeitungsprozesses. Wir haben ein umfassendes Qualitätskontrollsystem etabliert, das die gesamte Wertschöpfungskette abdeckt. Diese umfasst die Wareneingangskontrolle der Rohmaterialien, die laufende Prüfung während des Präzisionsstanzprozesses sowie die Endkontrolle der fertigen Produkte vor deren Auslieferung. Jede Produktionsstufe ist mit professioneller Prüfausrüstung und qualifizierten Prüfern ausgestattet. Wir verwenden hochpräzise Prüfgeräte wie Koordinatenmessgeräte und Projektoren. Diese Geräte prüfen umfassend die Abmessungen, Form und Lagetoleranzen der Präzisionsstanzteile. So stellen wir sicher, dass jedes Produkt die Qualitätsanforderungen unserer Kunden erfüllt. Darüber hinaus sind wir nach ISO 9001 und IATF 16949 für Qualitätsmanagementsysteme der Automobilindustrie zertifiziert. Dies bietet eine starke Garantie für die Produktqualität unserer Präzisionsstanzteile und -bearbeitungsprodukte.

Warum Sie sich für uns entscheiden sollten: Ihr zuverlässiger Partner für Elektromobilität

Als professioneller Hersteller von Metallstanzteilen orientieren wir uns stets an den Bedürfnissen unserer Kunden und treiben technologische Innovationen voran. Aufbauend auf unseren Stärken in der Präzisions- und kundenspezifischen Hochpräzisions-Metallstanzung bieten wir hochwertige Metallbauteile für Elektrofahrzeuge an und bedienen damit die Branche der alternativen Energien.

Wir verfügen über ein erfahrenes technisches Team mit Mitgliedern, die über jahrelange Erfahrung in der Metallstanztechnik verfügen. Dank ihrer Expertise in Kerntechnologien wie hochpräzisem Stanzen und kundenspezifischem Stanzen bieten sie unseren Kunden professionellen technischen Support und maßgeschneiderte Lösungen. Gleichzeitig investieren wir kontinuierlich in Forschung und Entwicklung, bleiben stets über die neuesten technologischen Trends der Branche informiert und optimieren unsere Stanzprozesse und -anlagen. Dies steigert die Präzision und Effizienz unserer Stanzvorgänge und schafft so einen Mehrwert für unsere Kunden.

Im Bereich Service haben wir ein solides Kundendienstsystem etabliert. Von der Programmberatung über die Musterfertigung bis hin zur Serienproduktion und dem After-Sales-Service bieten wir unseren Kunden während des gesamten Prozesses professionelle und effiziente Unterstützung. Wir garantieren, innerhalb von 24 Stunden nach Eingang Ihrer Anfrage erste Lösungsvorschläge zu unterbreiten. Die Musterfertigung dauert maximal 7 Tage. Die Lieferzeit für die Serienproduktion wird flexibel an die Bestellmenge angepasst. Wir stellen sicher, dass unsere Kunden die benötigten Präzisions-Metallstanzteile und Stanzteile termingerecht erhalten.

Wenn Sie Probleme mit dem Stanzen von Metallteilen für Elektrofahrzeuge haben und hochwertige Präzisionsstanzteile oder kundenspezifische Stanzlösungen für anspruchsvolle Anwendungen benötigen, kontaktieren Sie Vanmodel Sheet Metal. Wir entwickeln maßgeschneiderte Lösungen, die genau auf Ihre Bedürfnisse zugeschnitten sind. Wir helfen Ihnen, sich mit Ihren Produkten für Elektrofahrzeuge im Wettbewerb zu behaupten und gemeinsam die Weiterentwicklung der Elektromobilität voranzutreiben!