Metallstanzen

Beschreibung

Was ist Metallprägen?

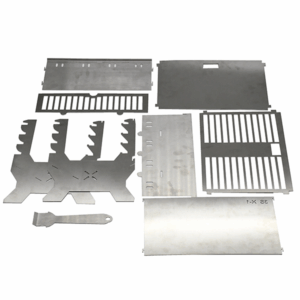

Die Metallstanzung ist ein hocheffizientes Fertigungsverfahren, das flaches Blech (Stahl, Aluminium, Messing usw.) in präzise, komplexe Bauteile umwandelt. Dabei werden spezielle Werkzeuge verwendet, die als Stanzwerkzeuge bezeichnet werden. Stanzwerkzeuge Mithilfe leistungsstarker Pressen werden Schneiden, Biegen, Stanzen, Prägen und Umformen in schneller Folge durchgeführt – oft werden Teile in Sekundenschnelle fertiggestellt.

Warum Industrien auf Stanzverfahren angewiesen sind:

-

Kosteneffizienz: Ideal für die Massenproduktion, wodurch die Stückkosten deutlich gesenkt werden

-

Präzision und Konsistenz: Hält Toleranzen innerhalb von ±0,05 mm über Millionen von Teilen hinweg ein.

-

Materialvielfalt: Verarbeitet alles von dünnen Folien (0,1 mm) bis hin zu dicken Platten (6,0 mm+).

-

Komplexe Geometrie: Erzeugt komplexe Formen, die mit maschineller Bearbeitung oder Guss nicht möglich sind.

Wichtigste Stanzverfahren, die wir beherrschen:

-

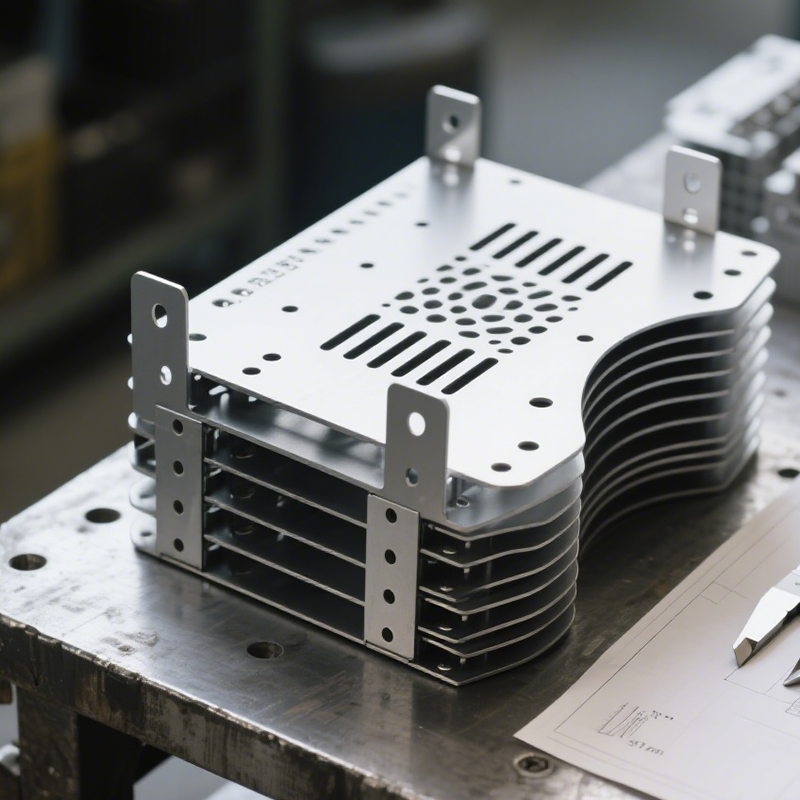

Folgeverbundstanzen: Mehrere Arbeitsgänge werden nacheinander in einem einzigen Werkzeug durchgeführt, wobei das Spulenmaterial durch automatisierte Pressen geführt wird. Ideal für Steckverbinder, Halterungen und elektrische Kontakte.

-

Transferstempelung: Die Teile werden mittels mechanischer Transfersysteme zwischen den jeweiligen Stationen bewegt. Ideal für größere Bauteile wie z. B. Strukturbauteile im Automobilbereich.

-

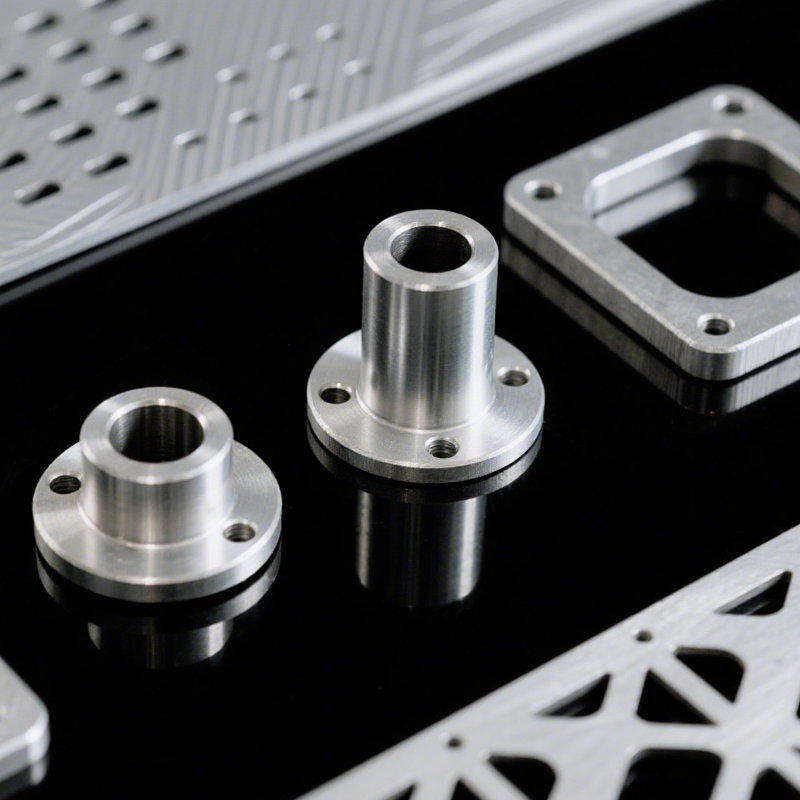

Feinstanzen: Liefert ultra-glatte, gratfreie Kanten für kritische Anwendungen. Unverzichtbar für medizinische Geräte und Präzisionszahnräder.

-

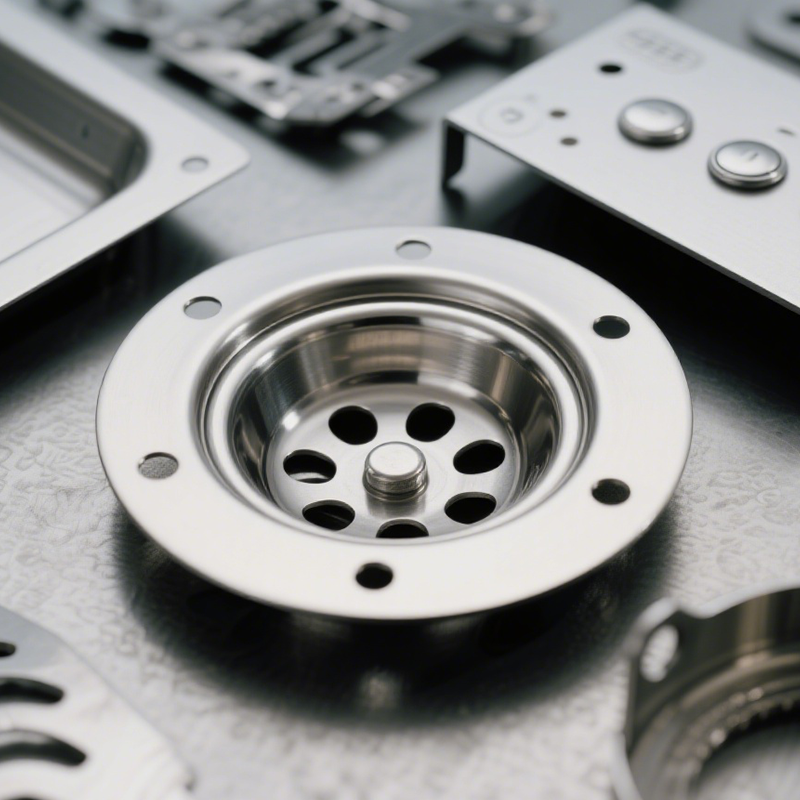

Tiefziehen: Formt Bleche zu nahtlosen 3D-Formen (Becher, Gehäuse, Zylinder). Wird für Spülbecken, Gehäuse und Abschirmungskomponenten verwendet.

Über die Presse hinaus: Unsere Mehrwertdienste

-

Werkzeugexzellenz: Eigene Konstruktion und Fertigung von Präzisionsstanzwerkzeugen

-

Integrierte Sekundäroperationen:

-

CNC-Bearbeitung für kritische Merkmale

-

Oberflächenveredelung (Galvanisieren, Pulverbeschichten, Anodisieren)

-

Automatisiertes Schweißen und Montage

-

-

Qualitätssicherung: Echtzeitüberwachung mit im Werkzeug integrierten Sensoren, CMM-Inspektion und Materialrückverfolgbarkeit

Materialwissenschaftliche Expertise:

Wir stempeln:

-

Kohlenstoff- und Edelstahl

-

Aluminium- und Kupferlegierungen

-

Exotische Metalle (Inconel, Titan)

-

Spezialbeschichtungen (verzinkt, Aluzink)

Warum sollten Sie bei Ihren Stempelprojekten mit VanModel zusammenarbeiten?

-

Markteinführungsgeschwindigkeit: Schnelle Prototypenerstellung und Werkzeugentwicklung

-

Technischer Support: DFM-Optimierung (Design for Manufacturing)

-

Vertikale Integration: Vollständiger Produktionszyklus vom Rohmaterial bis zur fertigen Montage

-

Branchenkonformität: Erfüllt die Normen IATF 16949, ISO 13485 und die Luft- und Raumfahrtnormen.

Sind Sie bereit, die Vorteile der Präzisionsmetallstanzung für Ihr nächstes Projekt zu nutzen?

Entdecken Sie unsere fortschrittlichen Funktionen und fordern Sie noch heute ein Angebot an:

www.vanmodel-sheetmetal.com