Tiefziehen

Beschreibung

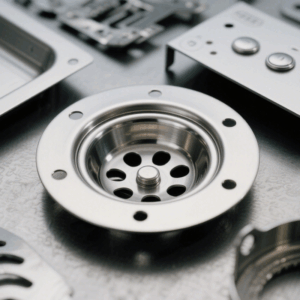

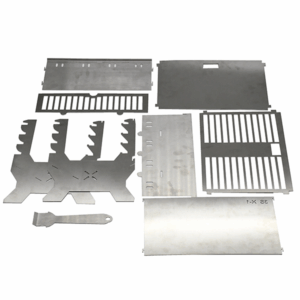

Präzisionstiefziehdienstleistungen für komplexe Metallbauteile

Tiefziehen ist ein fortschrittliches Blechumformverfahren, bei dem ein Blechzuschnitt durch die präzise mechanische Wirkung eines Stempels radial in ein Formwerkzeug gezogen wird. Diese ausgefeilte Formgebungstechnik erhält die Materialintegrität und ermöglicht die Herstellung tiefer, nahtloser Bauteile. Man spricht von Tiefziehen, wenn die Tiefe des Bauteils seinen Durchmesser übersteigt. Dadurch eignet sich das Verfahren ideal für die Fertigung komplexer, dreidimensionaler Geometrien.

Wichtigste Vorteile des Verfahrens:

-

Nahtlose Konstruktion – Herstellung komplexer, hohler Bauteile ohne Verbindungen oder Schweißnähte.

-

Materialeffizienz – Maximale Materialausnutzung bei minimalem Abfall

-

Strukturelle Integrität – Gleichmäßige Wandstärke und Materialfestigkeit gewährleisten

-

Hohes Produktionsvolumen – Ideal für die Massenproduktion mit gleichbleibender Qualität

-

Designvielfalt – Komplexe Geometrien aus einfachen Rohlingen herstellen

Unsere Tiefziehkapazitäten:

-

Mehrstufige Tiefziehprozesse

-

Kundenspezifische Werkzeug- und Formenkonstruktion

-

Verschiedene Presskapazitäten und Konfigurationen

-

Integration der Sekundärprozesse

-

Präzise Steuerung des Durchmesser-Tiefen-Verhältnisses

Materialexpertise:

-

Edelstahl und Kohlenstoffstahl

-

Aluminium- und Kupferlegierungen

-

Spezialmetalle und beschichtete Werkstoffe

Qualitätssicherung:

Jedes Tiefziehteil wird einer strengen Prüfung auf Maßgenauigkeit, Oberflächenqualität und strukturelle Integrität unterzogen, um die Einhaltung internationaler Normen und Kundenspezifikationen zu gewährleisten.

Branchenanwendungen:

-

Automobilkomponenten und Kraftstoffsysteme

-

Teile für Luft- und Raumfahrt sowie Verteidigung

-

Gehäuse für medizinische Geräte

-

Elektronikgehäuse und -abschirmungen

-

Industriecontainer und Gehäuse

-

Komponenten von Konsumgütern

Technischer Support:

-

Analyse der Herstellbarkeit im Design

-

Prototypenentwicklung und -prüfung

-

Produktionsoptimierung

-

Kundenspezifische Engineering-Lösungen

[Technische Beratung anfordern] oder [Detailliertes Angebot anfordern]