Präzisions-Metallstanzwerkzeuge

Beschreibung

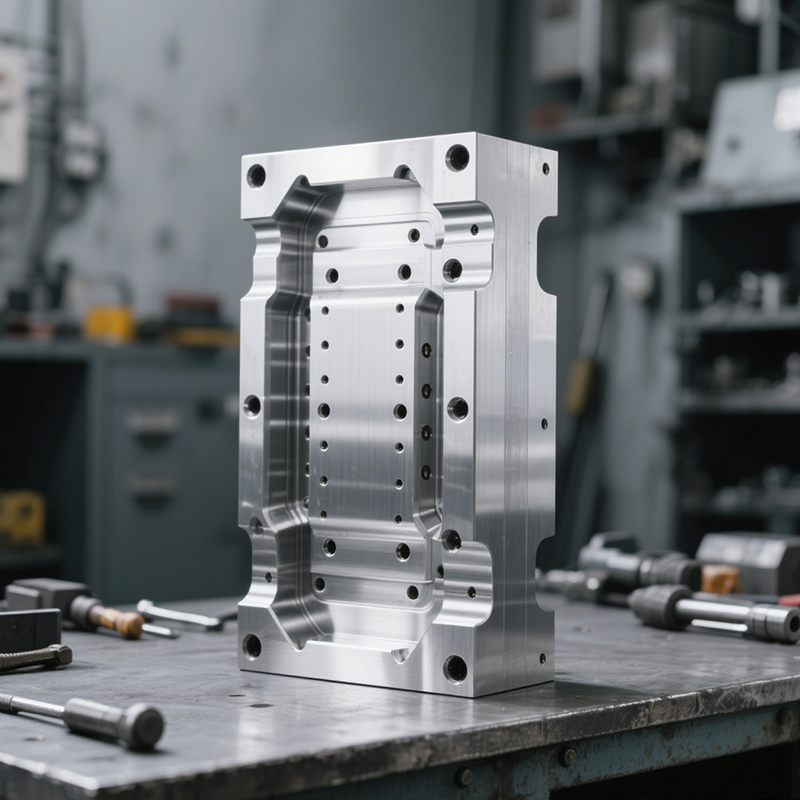

Präzisionsmetallformen: Entwickelt für höchste Qualität in der Serienfertigung

Das Herzstück jeder makellos gefertigten Komponente ist eine meisterhaft gestaltete Präzisionsmetallform. In der Tat, Es ist mehr als nur ein Werkzeug, es dient als Grundstein Ihrer Produktionslinie und bestimmt direkt die Endproduktqualität, die Fertigungseffizienz und die Kosten pro Teil. Entsprechend, VanModel ist spezialisiert auf die Entwicklung und den Bau dieser Hochleistungsformen – die zuverlässigen Motoren Ihrer Massenproduktion. Dort Wir garantieren, dass jedes einzelne Teil, vom ersten bis zum millionsten, mit unübertroffener Konstanz exakten Spezifikationen entspricht.

Warum sollten Sie bei Ihren Präzisionsformen mit VanModel zusammenarbeiten?

Kompromisslose Genauigkeit und Wiederholbarkeit

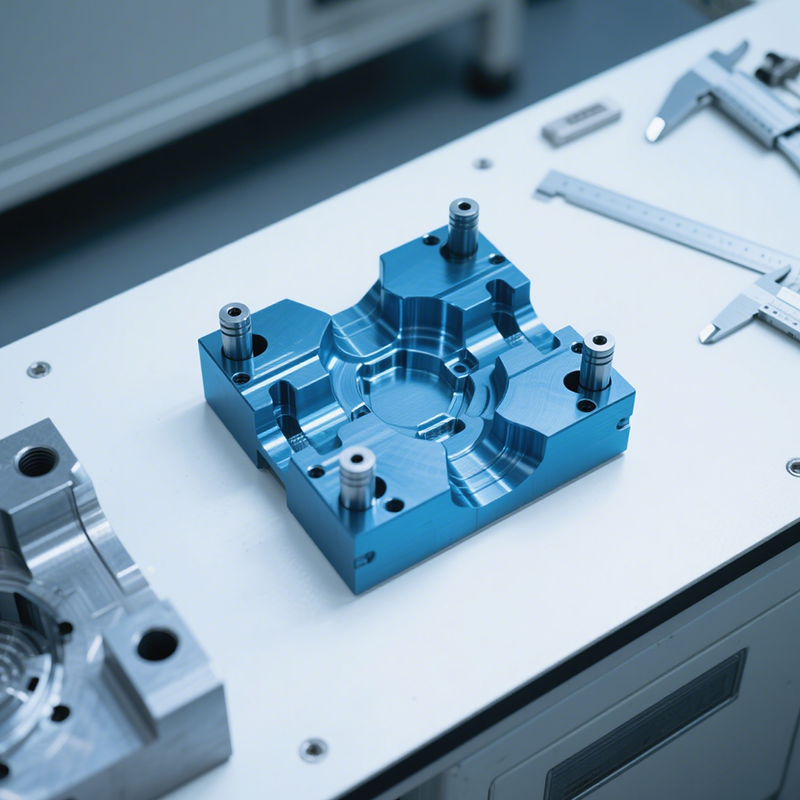

Wir konstruieren Formen, die extrem enge Toleranzen einhalten und Präzisionswerte von bis zu ±0,005 mm erreichen. Folglich, Dadurch werden Abweichungen zwischen den einzelnen Teilen eliminiert. was ist insbesondere wichtig für komplexe Baugruppen in anspruchsvollen Branchen wie der Luft- und Raumfahrt, der Medizintechnik und dem Automobilbau.

Überragende Haltbarkeit und Langlebigkeit

Seit Unsere Formen werden aus hochwertigen, gehärteten Werkzeugstählen gefertigt und fortschrittlichen Wärmebehandlungsverfahren unterzogen. Sie widerstehen extremem Druck und abrasivem Verschleiß über Millionen von Zyklen mit hohem Produktionsvolumen. Infolge, Dies führt zu einer drastisch verlängerten Lebensdauer. dadurch Minimierung von Produktionsausfallzeiten und Reduzierung Ihrer langfristigen Werkzeugkosten.

Optimiert für maximale Produktionseffizienz

Unsere Expertise liegt in der Entwicklung fortschrittlicher Formen für Verfahren wie Stanzen, Druckgießen und Spritzgießen, die auf maximalen Durchsatz optimiert sind. Zum Beispiel, Intelligente Funktionen wie Mehrfachkavitäten-Layouts und progressive Arbeitsabläufe reduzieren die Zykluszeiten erheblich. daher wodurch Ihre Gesamtleistung und Markteinführungszeit beschleunigt werden.

Eine umfassende Ingenieurpartnerschaft

Darüber hinaus, Wir bieten mehr als nur eine Form; wir liefern eine komplette Fertigungslösung. Speziell, Unser Team bietet Ihnen von Anfang an eine fachkundige Analyse der fertigungsgerechten Konstruktion (Design for Manufacturability, DFM) und arbeitet mit Ihnen zusammen, um die Teilekonstruktion für den Spritzgießprozess zu optimieren. Daher, Dies gewährleistet eine reibungslose Fertigung, verbessert die Leistung des Endprodukts und beugt kostspieligen Problemen in der Zukunft vor.

Unsere Leistungen im Überblick:

-

Prozesse: Präzisionsstanzformen, Druckgussformen, Spritzgussformen

-

Bediente Branchen: Automobilindustrie, Luft- und Raumfahrt, Medizintechnik, Unterhaltungselektronik

-

Hauptunterscheidungsmerkmal: Integrierte DFM-Unterstützung und das Engagement für eine langfristige Partnerschaft im Engineering-Bereich.

Bereit, Ihre Produktion mit Präzision anzutreiben?

Daher, Wenn Sie Formen suchen, die nicht nur auf Präzision, sondern auch auf Leistung und Partnerschaft ausgelegt sind, kontaktieren Sie VanModel noch heute, um Ihr Projekt zu besprechen.

[Kostenlose DFM-Beratung anfordern] | [Individuelles Angebot anfordern]