Precision Stamping of Micro-Parts for 3C Products

3C products—smartphones, wearables, laptops—are rapidly trending toward slimmer, higher-performance designs. Crucially, micro-part precision and reliability directly define end-product quality. As a core 3C industry support, custom precision metal stamping services expertly master small-size, high-tolerance requirements. Therefore, they have become strategic partners for many 3C enterprises. From phone motherboard micro-springs to smartwatch conductive terminals, precision metal stamping parts quality directly impacts 3C product stability. Essentially, professional metal stamping manufacturing capabilities are the core guarantee for this quality.

Small Size, Big Challenges: Custom Precision Stamping Solves 3C Part Pain Points

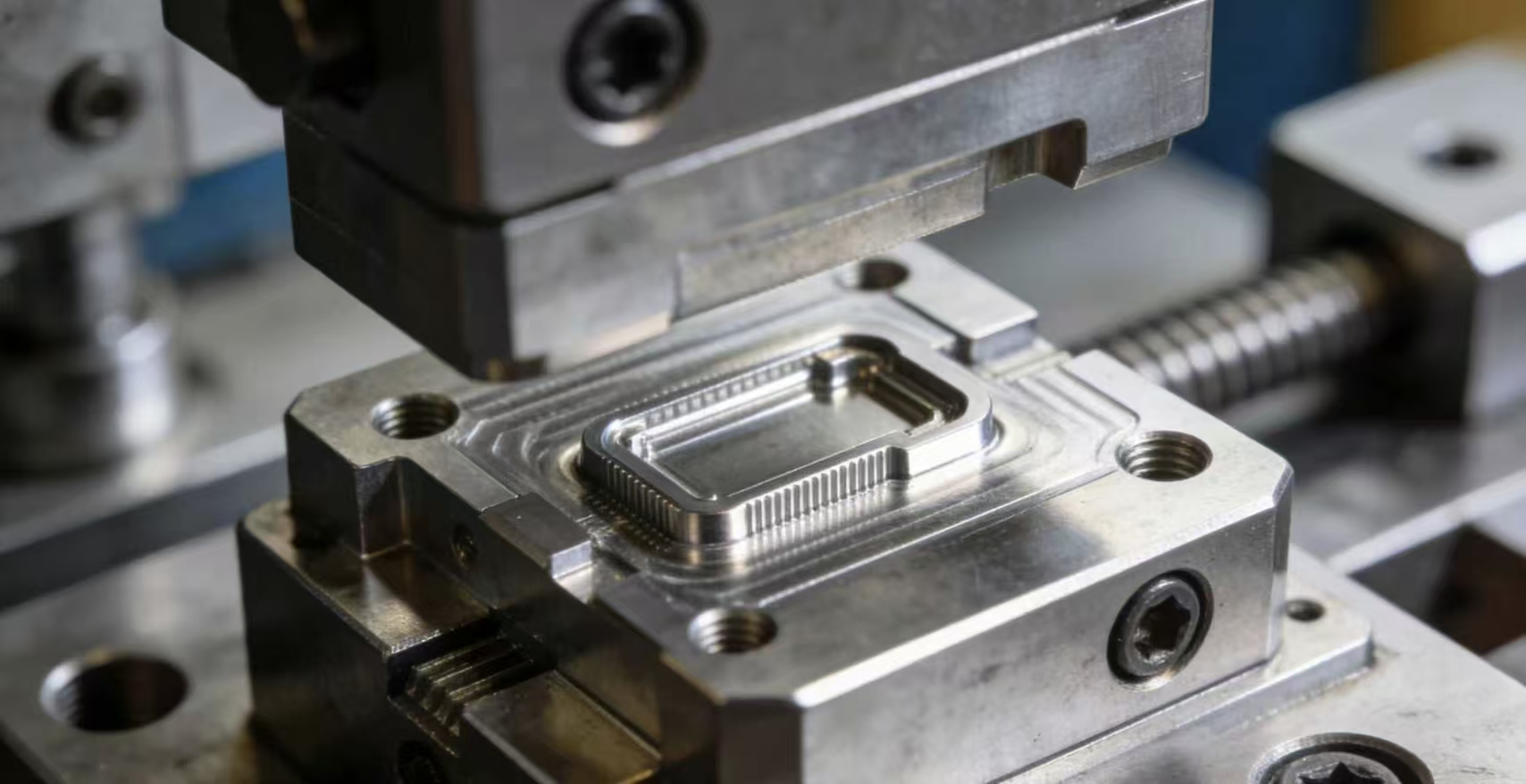

3C micro-parts typically feature small dimensions, complex structures, and stringent precision. Unfortunately, conventional stamping struggles to meet these needs. For example, a foldable phone hinge component measures just 2mm×1mm. Moreover, it requires a tolerance of ±0.01mm. This means the process demands top-tier stamping equipment, mold precision, and process control. Thankfully, custom precision metal stamping services are designed to address these needs. Specifically, they use customized process design, high-precision molds, and full-process quality control. Ultimately, they perfectly fit 3C micro-part production requirements.

In production, custom precision metal stamping services first optimize parameters by material and use case. Common materials include stainless steel, copper alloy, and aluminum alloy. For conductive micro-terminals, for instance, high-purity copper is used. Additionally, multi-pass precision stamping ensures conductivity and structural strength. For lightweight camera brackets, on the other hand, aluminum alloy is chosen. Furthermore, precision stamping and surface treatment achieve “light yet sturdy” performance. Importantly, every step of making precision metal stamping parts relies on metal stamping manufacturing technology. In practice, full-process refined management ensures consistent part quality, including raw material cutting, stamping, and inspection.

Many 3C enterprises often face the issue of “qualified samples but unstable mass production”. In fact, this stems from immature metal stamping manufacturing systems. Conversely, professional custom precision stamping providers proactively build a full-chain system. This system covers mold validation to mass production control. They also use automated stamping equipment and inline inspection systems. These tools effectively minimize production errors. As a result, every batch of precision metal stamping parts meets 3C standards. As Stamping Factory Pitfalls: Sample to Mass Production Guide ¿Cómo elegir una fábrica de chapa metálica de precisión? Puntos clave aquí. notes, stable mass production is key to a provider’s strength. Notably, this is especially true for 3C micro-parts.

Technological Iteration: The Code to Upgrade Precision Stamping Part Quality

3C product functions keep advancing at a fast pace. Naturally, performance demands for core components applied in related devices rise continuously. For example, 5G phones need better electromagnetic shielding for signal transmission. Similarly, wearable battery contact plates require excellent wear resistance and conductivity. To meet these evolving needs, custom precision metal stamping services actively drive technological iteration. Specifically, they combine precision metal machining with stamping to achieve dual improvements in part precision and overall performance.

In mold development, custom precision stamping services first use high-precision CNC machines. Crucially, mold precision directly determines part dimensional accuracy. Additionally, special mold surface treatments reduce friction during stamping. This not only extends mold life but also cuts production losses. In stamping processes, furthermore, multi-station continuous stamping is adopted. It integrates cutting, forming, and punching into one line. As a result, this boosts efficiency and avoids part damage from repeated handling. Ultimately, it ensures consistent dimensions of precision metal stamping parts.

For high-precision uses like chip heat dissipation components, for instance, laser inspection is introduced. It conducts full-dimensional testing of each precision metal stamping part. Impressively, detection accuracy reaches 0.001mm. This ensures full compliance with design requirements. Moreover, collaboration with precision sheet metal fabrication firms enables integrated supply. This supply chain covers micro-stampings to full sheet metal assemblies. Consequently, it offers more efficient solutions for 3C enterprises. As Why Custom Stamping Is Indispensable for High-Precision AppsEstampado de metales personalizado para alta precisión: Abordando los desafíos en el estampado de piezas metálicas para vehículos eléctricos details, custom service value is significant. Clearly, this value is fully reflected in 3C micro-part production.

Full-Chain Assurance: Core Competitiveness of Metal Stamping Manufacturing

A mature metal stamping manufacturing system is absolutely key to ensuring stable 3C micro-part supply. Professional providers comprehensively offer full-process services. These include design optimization, mold development, sample validation, and mass production delivery. In design, for example, engineers provide suggestions based on stamping characteristics to optimize part structures. This cuts production difficulty and costs effectively. In mold development, additionally, rapid prototyping shortens cycles. This allows clients to validate samples faster. In mass production, furthermore, automation and intelligent systems enable real-time monitoring and data traceability. Ultimately, this ensures consistent quality of precision metal stamping parts.

The 3C industry is known for rapid iteration. Therefore, metal stamping manufacturing needs fast response capabilities. Professional providers proactively build flexible production scheduling systems. They prioritize resources for urgent orders to shorten delivery times. Additionally, a robust supply chain system ensures stable, quality-controlled raw material supply. This effectively prevents delays from material issues. In after-sales, moreover, regular quality feedback and technical support are provided. We promptly resolve client issues with precision metal stamping parts. As a result, we form a “production-delivery-service” closed loop.

EV and 3C industries are currently integrating closely. Interestingly, ev metal parts stamping technology offers new ideas for 3C micro-stamping. For in-vehicle 3C parts, for instance, EV high-strength stamping processes are borrowed. This enhances part impact resistance to meet in-vehicle needs. Importantly, all these technologies and services rely on custom precision stamping capabilities. They also depend on metal stamping manufacturing technical accumulation.

Choose a Reliable Partner for Precision Collaboration

3C product quality competition is ultimately core part quality competition. Precision metal stamping parts are often referred to as the “bones and muscles” of 3C products. Their precision and reliability directly determine end-product market competitiveness. Custom precision metal stamping services not only offer customized solutions but also have high-precision production capabilities. They also provide full-process support, making them key to 3C enterprise quality upgrades. Professional metal stamping manufacturing providers can adapt to small-batch custom samples. They also handle large-scale mass production needs efficiently. Ultimately, they create greater value for clients.

If you are currently seeking a reliable partner for 3C micro-part stamping, please contact vanmodel sheet metal now. We comprehensively provide professional custom precision metal stamping services. We also help you obtain high-precision compliant precision metal stamping parts. Ultimately, we will significantly boost your products’ market competitiveness.