Industria de semiconductores

The Invisible Battlefield in Semiconductor Manufacturing: How a 0.2μm Warp Can Render $5 Million Worth of Wafers Useless

A vacuum failure costing hundreds of thousands of dollars stems from a tiny warp invisible to the naked eye.

In the world of semiconductor manufacturing, a relentless battle is being fought at the microscopic scale. Here, the adversaries are invisible, and the outcomes of these battles are decided at the micron or even nanometer level.

When a multi-million-dollar EUV lithography machine loses vacuum due to a minuscule warp in a FOUP door, or when $5 million worth of 3nm wafers are scrapped due to particulate contamination—these are not isolated incidents but extreme examples of the daily challenges in semiconductor precision manufacturing.

In this pursuit of extreme precision, traditional manufacturing methods can no longer meet the demanding requirements of semiconductor equipment. As a partner to ASML, Lam Research, and Applied Materials suppliers, Vanmodel Sheet Metal is redefining the manufacturing standards for core components in semiconductor equipment.

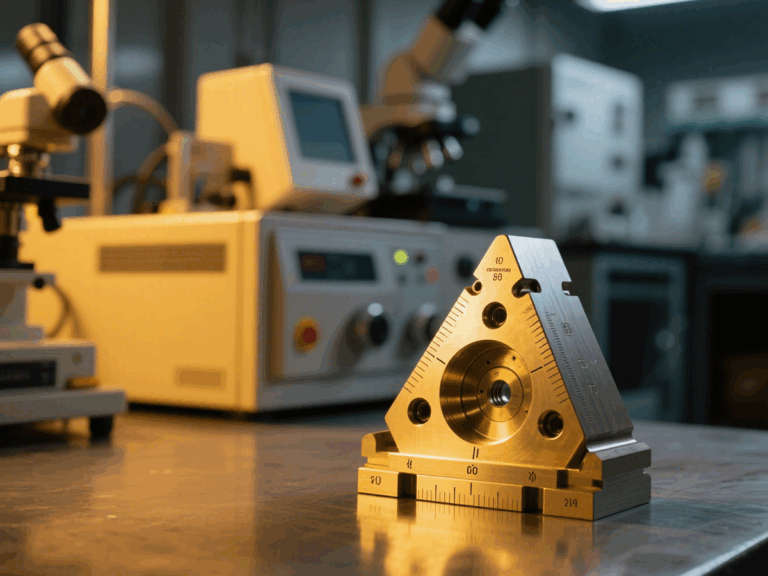

Precision is Everything: The Flatness Revolution in Semiconductor Equipment

A warp of just 1μm/m² is enough to compromise vacuum seals—a requirement that becomes even more critical in advanced processes like Extreme Ultraviolet Lithography (EUV). As the core container for wafer transport and storage within fab facilities, the FOUP’s (Front-Opening Unified Pod) sealing performance directly determines the production line’s yield.

The root cause often lies in internal material stresses. Components in semiconductor equipment develop internal stresses during processing, which release over time, leading to gradual deformation during use. To address this, we implement a 48-hour thermal aging process at 300°C, stabilizing the crystal structure of 6061-T651 aluminum alloy at the material source by precisely controlling the temperature curve, thereby preventing future deformation.

In flatness processing, we combine surface grinding technology with laser interferometer detection to achieve 0.5μm flatness. This level of precision is equivalent to variations no greater than the diameter of a human hair across an area the size of a football field—a standard unattainable through traditional manufacturing methods.

Welding distortion presents another critical challenge. Our pulsed TIG welding process with argon back-purging effectively controls heat input, minimizing welding distortion. This technique ensures FOUP doors maintain excellent sealing flatness post-welding.

Contamination Control: Guardians of Semiconductor Yield

Semiconductor manufacturing environments demand extremely stringent contamination control. A single microscopic particle can lead to the loss of wafers worth tens of thousands of dollars. Research shows that molecular contamination inside FOUPs directly causes wafer defects, including crystal growth issues and metal interconnect corrosion.

Cleanroom control serves as the first line of defense against contamination. Nuestro Class 5 cleanrooms ensure that the particle count for critical component manufacturing remains strictly below 3,520 particles/m³—a standard far exceeding that of conventional manufacturing environments.

Surface treatment technology is equally crucial. Nuestro electropolishing process achieves a surface roughness of Ra<0.1μm, which not only reduces particle adhesion areas but also significantly lowers material outgassing rates. Studies indicate that proper surface treatment can reduce the outgassing rates of stainless steel and aluminum alloys by several times.

In passivation treatment, we have adopted an environmentally friendly citric acid passivation process to replace traditional nitric acid passivation. This shift maintains the passivation effectiveness on stainless steel surfaces while substantially reducing environmental impact—a change widely recognized by numerous semiconductor manufacturers.

From CAD to Fab: The Speed Advantage in Semiconductor Innovation

In the high-stakes semiconductor industry, time-to-market is directly proportional to market share. The ability to rapidly iterate and validate component designs directly impacts our clients’ competitive edge.

We have compressed the FOUP prototyping cycle from the industry standard of 6 weeks to just 10 days—from CAD design to functional pod. This acceleration is made possible by our integrated manufacturing approach and zero-particulate deburring technology using Magnetic Abrasive Finishing (MAF).

Our equipment capabilities include:

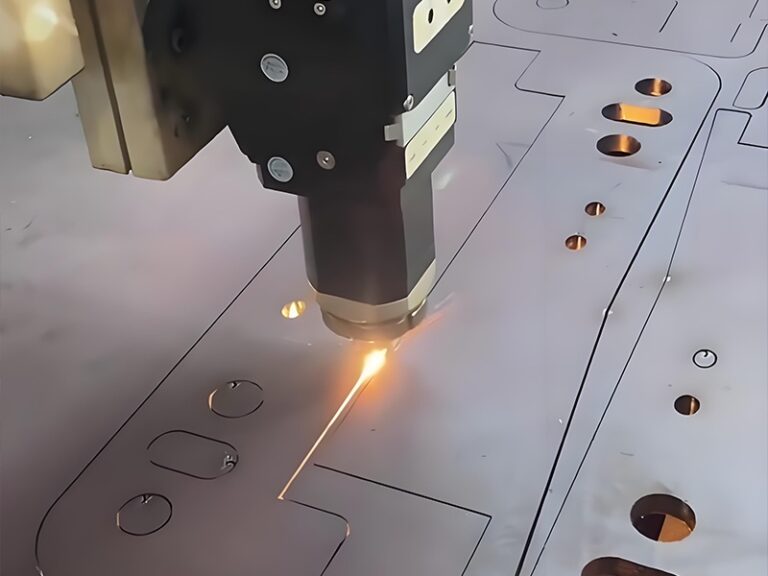

- AMADA LC-3015 F1 6kW laser cutting system with ±0.03mm precision

- Certified 6061-T651 aluminum and 304/316L stainless steel materials with low outgassing properties

- Helium leak testing capabilities down to 1×10⁻⁹ Pa·m³/s

One semiconductor equipment manufacturer attested: “Vanmodel’s FOUP doors maintained a vacuum below <0.01Pa for over 200 cycles—matching OEM specifications at a 40% lower cost.”

Conclusion: Precision Without Compromise

In semiconductor manufacturing, there is no room for compromise. Every micron, every surface finish, and every material choice carries profound implications for final yield.

Vanmodel Sheet Metal brings semiconductor-grade precision to every component we manufacture. From material selection and processing to final inspection, we maintain standards that meet or exceed industry requirements.

Exija precisión de grado semiconductor

Descargue nuestra hoja de especificaciones de planitud FOUP

Vanmodel Sheet Metal—Precision Components for the Semiconductor Industry

Trusted by suppliers to ASML, Lam Research, and Applied Materials