Estampage de précision pour instruments dentaires

In the field of dental care, instrument precision directly impacts treatment outcomes and patient safety. Crucially, the key process to meet this core requirement is precision metal stamping technology. From tiny dental implant components to precise orthodontic brackets, every dental stamped part bears medical responsibilities. Therefore, this demands precision metal stamping surpass conventional industrial standards. Specifically, it must achieve remarkable medical-grade micron-level precision. As a specialized high-end sector in metal stamping manufacturing, dental instrument stamping needs advanced equipment and technologies. Moreover, it also requires deep understanding of medical needs and uncompromising quality pursuit.

Medical-Grade Mandate: Precision Metal Stamping Defines Dental Instrument Precision Baseline

Dental instruments are unique. In fact, they are used in the narrow, complex oral cavity. Files for root canal therapy and crown bridge components for tooth restoration all need high dimensional accuracy. Additionally, they also require strict morphological consistency. This means the requirement passes directly to the precision metal stamping process. Only then can micron-level error control ensure stamped parts meet clinical standards. For example, a 5-micron curvature error in orthodontic traction hooks may cause imbalanced force. Consequently, it can affect tooth straightening results.

In precision metal industries, dental instrument stamping has the highest precision demands. By contrast, general industrial stamped metal parts allow tens of microns of error. Dental-specific stamped components need error control within 2–5 microns. Even more strictly, some core components even require zero error. This stringent standard compels metal stamping manufacturers to upgrade technologies continuously. In practice, they must refine every detail from mold design and material selection to stamping processes.

To understand high-precision stamping application logic, read Everything You Need to Know: Why Custom Metal Stamping Is Indispensable for High-Precision Applications. Notably, its core viewpoint aligns with dental instrument stamping demands. Essentially, high-precision applications rely on full industrial chain collaboration, not single technologies. For precision metal stamping, this collaborative concept must guide every stage of dental instrument production. Ultimately, it ensures every stamped component becomes a “precision benchmark”.

Technological Breakthroughs: Multi-Dimensional Assurance System Behind Precision Stamped Components

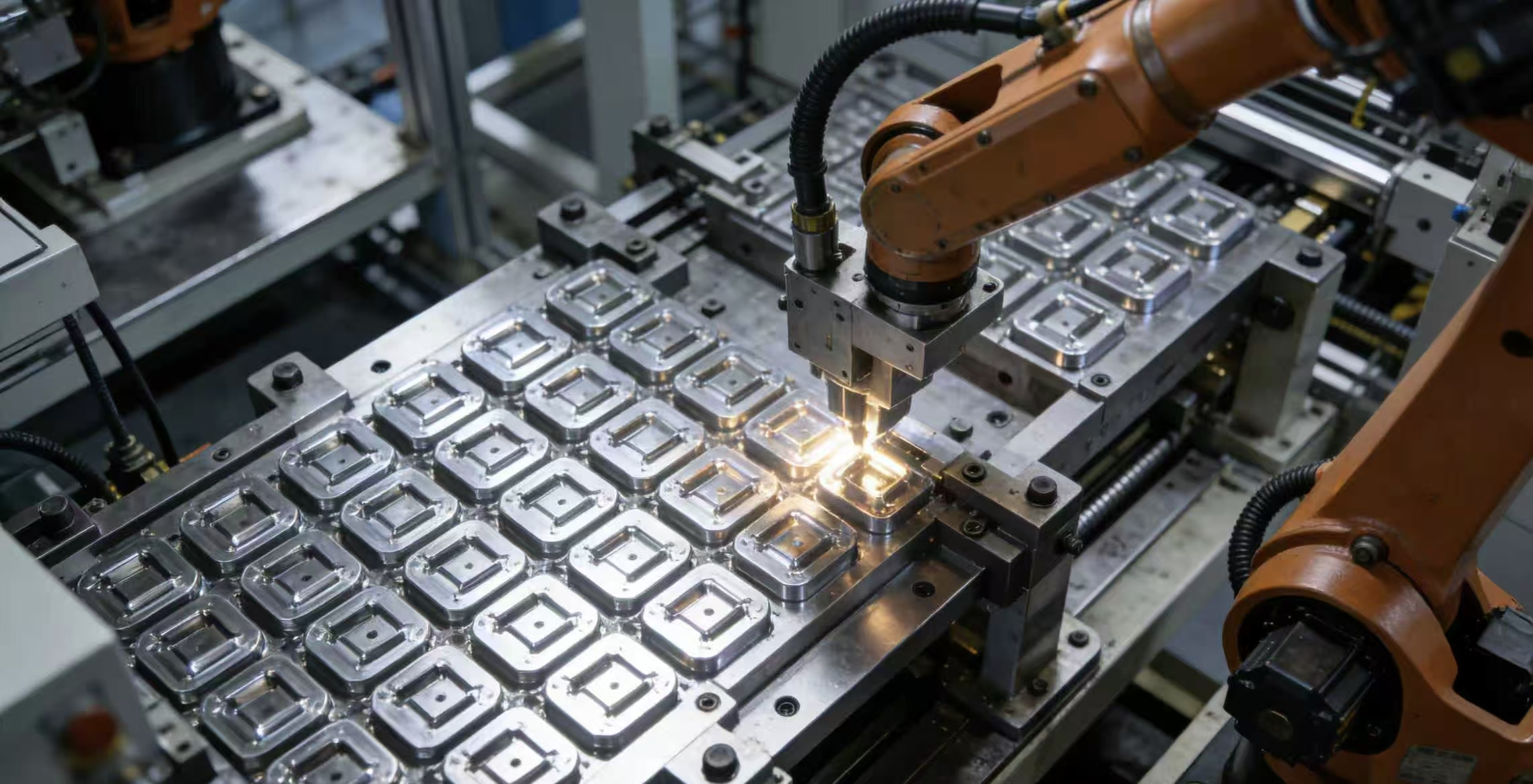

Producing a qualified dental stamped part is like a “precision project in the micro-world”. First and foremost, material selection must use medical-grade stainless steel or titanium alloy. These materials need excellent biocompatibility and stable physical properties. Importantly, they must withstand high-pressure deformation in precision metal stamping. In mold manufacturing, high-precision CNC machining is essential. Specifically, it controls mold dimensional error within 1 micron. Because mold precision directly determines the quality of stamped parts.

In the stamping phase, automated production lines and real-time monitoring systems are crucial. For one thing, automated equipment ensures consistent stamping operations. Thus, it avoids errors from manual operation. For another, real-time monitoring systems inspect each part’s size and shape instantly. Defective products trigger alarms and get removed immediately. This way, it ensures quality from the source. Meanwhile, precision metal machining and stamping collaboration strongly improves product precision. Furthermore, subsequent precision machining optimizes surface roughness and dimensional accuracy of stamped components.

For custom precision metal stamping services, dental instrument demands are more challenging. In particular, different dental treatments need instruments with different structures. This requires metal stamping manufacturers to have rapid response capabilities. Practically speaking, they must design exclusive stamping solutions per customer needs. The article Emboutissage de métal sur mesure pour une haute précision : relever les défis de l’emboutissage de pièces métalliques pour véhicules électriques points out a core principle. Namely, customized services must “accurately match needs with technologies”. This is fully reflected in dental instrument precision metal stamping. For example, every link from clinical need analysis to final delivery requires close coordination.

Application Expansion: Precision Metal Stamping Empowers Full-Range Dental Instrument Development

Dental medical technology advances rapidly. Correspondingly, instrument varieties expand continuously. As a result, precision metal stamping progress enables R&D and mass production of new instrument categories. In dental implants, abutment components need precise fit with implants. Moreover, they have strict outer diameter accuracy requirements. Precision metal stamping produces these abutment accessories efficiently. It not only meets precision demands but also reduces medical costs. In pediatric dentistry, miniaturized instruments have stricter size requirements for stamped parts. Luckily, micron-level stamping control makes these small instruments safe and practical.

High-precision stamping technology from fields like ev metal parts stamping provides references for dental applications. However, dental instrument precision metal stamping has extra requirements. Specifically, it must meet medical-grade sterility and biocompatibility standards. Therefore, this requires adding special surface treatment and disinfection processes after stamping. In turn, it ensures stamped components can be directly used in medical scenarios. Precision metal processing and stamping collaboration is the key to achieving this goal. Additionally, subsequent grinding and polishing processes improve product precision and optimize surface performance.

For dental instrument enterprises, choosing a reliable precision metal stamping partner is critical. The article Comment choisir une usine de tôlerie de précision ? Voici les points clés. lists three core criteria. These include technical strength, quality control systems and industry experience. Importantly, all three points apply equally to the dental field. Only if you select suppliers with medical-grade stamping capabilities can you ensure stable quality of stamped parts. Ultimately, they safeguard patient safety effectively.

Quality Control Core: Full-Process Management of Stamped Components from Production to Delivery

Quality control of medical-grade stamped parts covers every link. Firstly, raw materials need comprehensive composition and mechanical property testing before warehousing. This ensures compliance with medical standards. Secondly, molds require key dimension calibration with high-precision equipment before use. It thus avoids product precision defects caused by mold errors.

During metal stamping manufacturing, a “full-process visualization” quality control model is adopted. For instance, each batch of stamped components has a dedicated quality file. It records stamping parameters and testing data for full traceability. Furthermore, three key precise metal production quality control points are introduced. These are process monitoring, sampling re-inspection and finished product full inspection. Collectively, they ensure every product meets precision requirements. In addition, precision sheet metal fabrication and stamping combination enables production of complex-structured dental instruments. As a result, it further expands the application scope of precision metal stamping.

Dental medical technology progresses fast. Naturally, requirements for precision metal stamping keep rising. In the future, artificial intelligence and big data will enable intelligent stamping process regulation. This will further improve precision stability and production efficiency of stamped parts. Also, continuous improvement of custom metal stamping for high-precision applications services will better meet personalized dental needs. Ultimately, it provides stronger support for dental medical industry development.

Take Action Now: Choose a Professional Partner to Build Solid Foundation for Dental Instrument Precision

Dental instrument precision relates to patient health and trust. Therefore, the quality of every stamped component cannot be compromised. If you need precision metal stamping solutions with medical-grade micron-level assurance, contact vanmodel sheet metal immediately. We provide high-quality custom precision metal stamping services with professional technology and comprehensive quality control systems. In short, we help your products stand out in market competition.