Emboutissage de précision des métaux

Là où la précision rencontre le volume

Vanmodel | Votre partenaire de confiance en emboutissage de précision des métaux

Vanmodel excelle dans l'emboutissage de précision de métaux en grande série. Nous produisons entre 50 000 et plus de 100 000 unités par an. Notre spécialité : les composants miniatures d'une épaisseur minimale de 0,05 mm (0,002 pouce). Nous travaillons avec des industries où la précision est primordiale.

Estampage de précision pour applications critiques

Nous collaborons avec des clients des secteurs médical, électronique et automobile. Ils exigent des tolérances serrées et une variation minimale. Nous emboutissons des matériaux d'une épaisseur de 0,05 mm à 2 mm. Des options de pré-placage sont également disponibles.

Polyvalence des matériaux

Nos capacités comprennent :

- aluminium et acier inoxydable

- Acier nickelé et pré-galvanisé

- acier laminé à froid (à haute et basse teneur en carbone)

- Laiton, bronze phosphoreux et cuivre

Pourquoi les tolérances sont importantes

Les tolérances définissent la précision des pièces. Même de petites erreurs peuvent compromettre des assemblages entiers, entraînant des pertes de temps, de matériaux et d'argent. Vanmodel allie modélisation CAO, outillage et emboutissage. Nous atteignons des tolérances serrées sans compromettre la conception.

Méthodes d'estampage avancées

Estampage progressif

Une bande métallique défile dans une presse. Chaque passage de presse contribue à la fabrication de la pièce. Ce procédé garantit des tolérances serrées. Les pièces finies sont ensuite automatiquement séparées et collectées.

Emboutissage profond

Ce procédé permet de créer des formes creuses et des cavités. Il aspire la matière dans une cavité de matrice. Nous obtenons des profondeurs constantes, conformes aux spécifications.

Découpage fin

Idéal pour les bords lisses et les surfaces planes. Nous traitons des matériaux jusqu'à 15 x 15 cm.

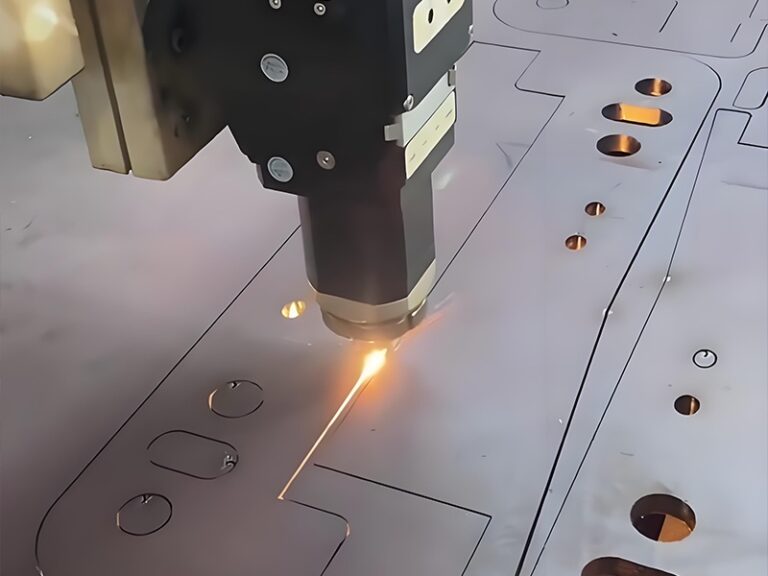

Perçage et découpe

Nous réalisons des perçages et des découpes précis. Ces opérations peuvent être effectuées isolément ou s'inscrire dans un processus progressif.

Pourquoi choisir Vanmodel ?

- Volume élevéProduction fiable de 50 000 à plus de 100 000 unités par an

- MicroprécisionComposants d'une épaisseur minimale de 0,05 mm (0,002″).

- Gamme de matériaux: Vaste choix, y compris des options pré-plaquées

- Équipe d'expertsDes décennies d'expérience dans la conception et la fabrication d'outils

- Priorité à la qualitéDes contrôles rigoureux garantissent une qualité constante

Démarrez votre projet

Contactez-nous pour nous faire part de vos besoins. Demandez un devis pour votre prochain projet. Découvrez pourquoi les fabricants font confiance à Vanmodel pour leurs composants essentiels.

Pour en savoir plus, consultez vanmodel-sheetmetal.com