Industrie des dispositifs médicaux

7 Critical Mistakes in Medical Enclosure Fabrication That Delay FDA Approval (And How to Solve Them)

When Dr. Elena Rodriguez’s biopsy forceps failed sterilization validation due to microscopic pitting in its 316L stainless steel housing, her FDA submission was delayed by 6 months. The supplier hadn’t accounted for autoclave-induced stress corrosion.

At Vanmodel Sheet Metal, we prevent these disasters for Class I-III medical device manufacturers. Here are the common failures in medical enclosures and our engineered solutions:

Mistake #1: Ignoring Autoclave Physics

The Problem: Repeated steam cycles create micro-fractures in thin-walled sections

Our Solution:

- Thermal Expansion Simulation: FEA analysis predicts warpage points before cutting metal

- Material Selection Optimization: Recommend suitable material specifications for different sterilization methods

- Case Study: We redesigned an insulin pump housing to withstand 500+ autoclave cycles

Mistake #2: Overlooking Particulate Traps

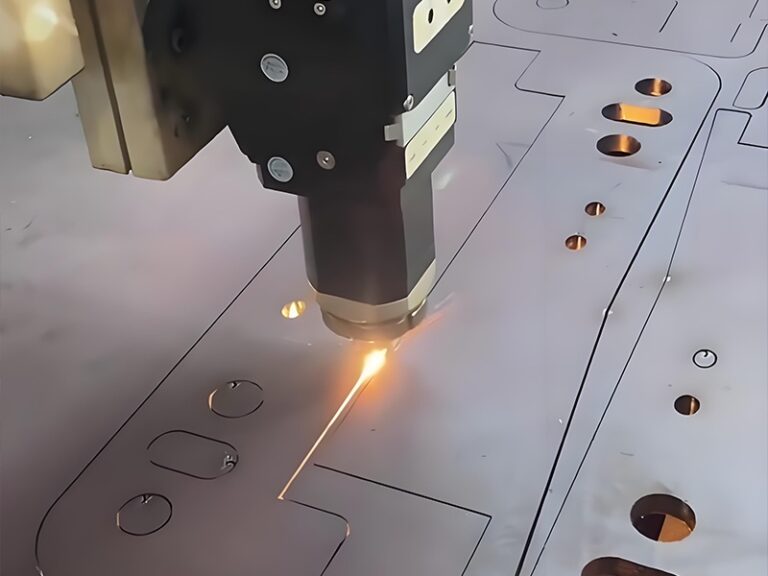

The Problem: Laser-cut edges trapping >5µm particles, failing ISO 14644-1 standards

Our Clean Protocol:

- ISO Class 5 Cleanroom manufacturing environment

- Micro-deburring achieving Ra<0.1µm surface roughness

- ESD Packaging ensuring cleanliness during transportation and storage

Mistake #3: Poor Weld Joint Design

The Problem: Heat-affected zones corroding after ethylene oxide sterilization

Vanmodel’s Fix:

- Argon-backpurged TIG Welding: Prevents atmospheric contamination

- Post-weld Solution Annealing: Eliminates welding stress, restores material properties

- ASTM A967 Passivation: Provides optimal corrosion resistance

Real Client Impact:

“Vanmodel re-engineered our endoscope casing with radiused corners and seamless welds – reducing bacterial adhesion by 92% in validation testing.”

— Quality Director, Orthopedic Device Startup

Mistake #4: Material Certification Gaps

The Problem: Missing MTRs (Mill Test Reports) halting FDA audits

Our Compliance Guardrails:

- EN 10204 3.1 Certificates: Complete traceability documentation for all metal materials

- USP Class VI Polymer Inserts: Meet highest biocompatibility standards

- Full Biocompatibility Documentation: Support 510(k) and PMA applications

Mistake #5: Inadequate Surface Roughness

The Problem: Excessive surface roughness providing hiding places for microorganisms

Our Finishing Technology:

- électropolissage: Achieves ultra-smooth Ra 0.15µm surfaces

- Micro-arc Oxidation: Provides wear-resistant, antimicrobial surfaces for aluminum alloys

- Validation Testing: Including microbial retention tests and cleaning validation

Mistake #6: Designing Without Cleaning Validation

The Problem: Complex geometries failing cleaning protocol validation

Our Design Approach:

- Cleanability Analysis: Evaluate every corner and crevice at design stage

- Radius Optimization: Ensure all internal corners meet minimum radius requirements

- Modular Design: Provide disassemblable solutions when needed

Mistake #7: Ignoring Supply Chain Traceability

The Problem: Inability to provide complete component traceability

Our Quality System:

- Batch Traceability: Complete records from raw materials to finished enclosures

- Electronic Traveler Cards: Real-time tracking of each component’s manufacturing history

- Audit-Ready Documentation: Prepared for FDA or notified body audits at any time

Why 200+ Medical Device Manufacturers Trust Vanmodel Sheet Metal

| Capability | Industry Standard | Our Performance |

|---|---|---|

| Surface Roughness | Ra 0.8µm | Ra 0.15µm |

| Prototype Lead Time | 4 weeks | 72 hours |

| Cleanroom Class | ISO 8 (100k) | ISO 5 (3.5k) |

| Laser Tolerance | ±0,1 mm | ±0.03mm |

Conclusion: Building Compliance from Design Start

In medical device manufacturing, every micron, every surface finish, and every material choice impacts patient safety and regulatory approval. By addressing these critical mistakes early in the design process, manufacturers can avoid costly delays and ensure successful FDA submissions.

Act Now to Prevent Regulatory Delays

[Download Free Checklist: “Medical Enclosure FDA Validation Requirements”]