Comment choisir une entreprise de métallurgie de précision ?

In the industrial manufacturing chain, precision metal components are the “invisible cornerstone” of the performance and reliability of end products. From motor cores of new energy vehicles to micro connectors of electronic equipment, their quality directly determines the product competitiveness of downstream industries. Therefore, choosing a precision metal enterprise with comprehensive strength is a key decision in the procurement link. The core standard for measuring enterprise strength lies in whether it has built a full-process capability of “precision metal stamping + precision metal machining + fabrication”. The three are like interlocking gears, indispensable. They jointly form the core barrier to serve the high-demand needs of various industries.

Precision Metal Stamping: The Core Technical Support of Precision Metal Enterprises

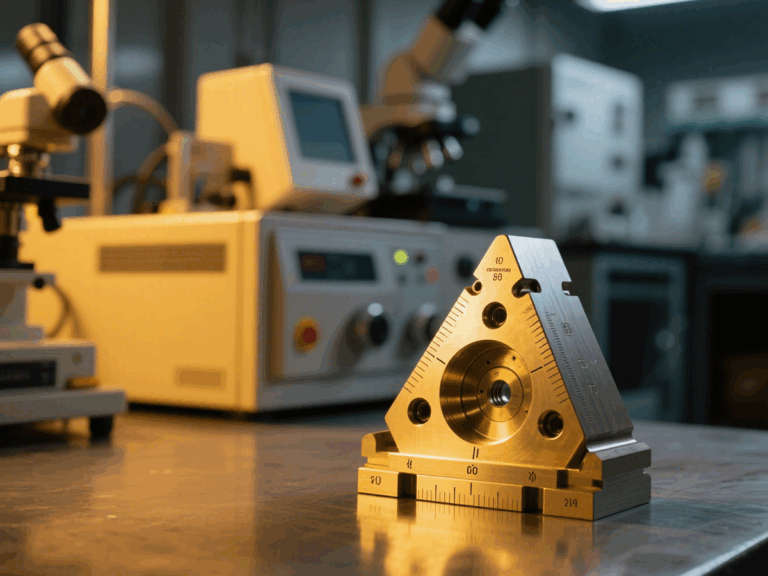

Precision metal stamping technology is a process that applies pressure to metal plates through molds to cause plastic deformation. This obtains precision components that meet design requirements. For precision metal enterprises, the precision, stability and efficiency of precision metal stamping directly affect product qualification rates and production cycles. Therefore, this technology has become one of the cores of enterprise competition.

High-quality precision metal stamping relies on three key factors. First, mold precision: High-precision molds control stamping part dimensional tolerances to the micron level, requiring professional teams to customize molds for automotive, electronics, new energy and other industries. Second, equipment performance: Advanced automated stamping equipment boosts efficiency, reduces metal loss, and uses computer systems for real-time process monitoring to ensure product consistency. Third, material adaptability: Different metals (stainless steel, aluminum alloy, copper alloy) have unique properties, so stamping parameters must be adjusted to avoid cracking or deformation, demanding rich material processing experience.

In practical applications, precision metal stamping has a very wide range of application scenarios. In the new energy vehicle field, ev metal part stamping relies on high-precision precision metal stamping technology. Key components in automobiles, such as battery tabs and motor cores, need to be mass-produced through this technology. They have extremely high requirements for the flatness and thickness tolerance of components. If the precision of precision metal stamping is insufficient, it may lead to reduced battery performance and abnormal motor operation. In addition, in the electronic equipment field, precision connectors and shielding covers in mobile phones and computers also need precision metal stamping to ensure their dimensional accuracy and assembly compatibility. It can be seen that precision metal stamping has become one of the core capabilities of precision metal enterprises to serve customers in various industries.

Metal Stamping Manufacturing: The Key Link to Realize Mass Production of Precision Components

If precision metal stamping is the core technology, then metal stamping manufacturing is the key link to implement the technology and realize mass production of precision components. Metal stamping manufacturing covers the entire process from raw material procurement, process planning, production execution to quality inspection. Its management level and production capacity directly determine whether the enterprise can stably and efficiently provide qualified products to customers.

Top precision metal stamping enterprises rely on a robust production management system. Raw materials undergo strict inspections for thickness, material and surface quality to meet stamping process requirements. Automated production lines enable continuous manufacturing, reducing manual errors, while MES tracks progress in real time to adjust plans and avoid delays. High-precision testing equipment (coordinate measuring machines, image measuring instruments) conducts full-size inspections on each batch to ensure products meet customer standards.

In addition, metal stamping manufacturing also needs to have efficient and flexible customized production capabilities. There are significant differences in the demand for metal stamping parts in various industries. For example, some customers need small-batch, high-precision customized components. Some customers need large-batch, standardized products. This requires the enterprise’s metal stamping manufacturing system to quickly respond to customer needs. It adjusts production parameters and production rhythms. Taking custom metal stamping for high-precision applications as an example, such demands often have special requirements for product precision and performance. Enterprises need to optimize process schemes during metal stamping manufacturing. They may even develop exclusive production processes to meet customers’ personalized needs. This customization capability has also become an important indicator to measure the level of metal stamping manufacturing.

Coordination of Stamping + Machining + Fabrication to Build a Complete Service Chain for Precision Metal Enterprises

In addition to having the two core capabilities of precision metal stamping and metal stamping manufacturing, precision metal enterprises also need to have excellent processing and fabrication capabilities. The three cooperate to build a complete service chain. They provide customers with one-stop precision metal solutions.

Processing capabilities mainly include precision metal machining. This process performs further refined processing on stamped metal components, such as drilling, milling, grinding, etc. It meets the higher precision requirements of components. For example, after stamping and forming, some precision metal stamping parts may have small defects such as burrs or dimensional deviations. Through precision metal machining, burrs can be removed and dimensions can be corrected. This ensures that the components can be assembled smoothly. At the same time, some precision components with complex structures cannot be fully processed only through stamping processes. They must be combined with precision metal machining to realize the manufacturing of complex structures. Therefore, processing capabilities have become an important support link to supplement the shortcomings of precision metal stamping and improve product precision.

Metal fabrication—assembling and forming metal components—is critical to integrating precision parts into complete assemblies. Take precision sheet metal fabrication: it involves cutting, bending, welding and assembly of sheet metal parts. It combines stamping or sheet metal components into finished products like industrial equipment enclosures and electronic equipment racks. Strong fabrication capabilities require professional assembly technology and a robust quality control system. This ensures that the assembled components meet standards in terms of structural strength, dimensional accuracy and appearance quality. The coordinated cooperation of stamping, machining and fabrication can greatly shorten the customer’s procurement cycle and reduce supply chain management costs. This is also the core competitiveness of high-quality precision metal enterprises.

How to Comprehensively Evaluate the Service Capabilities of Precision Metal Enterprises?

After understanding the core capabilities of precision metal enterprises, enterprises need to conduct a comprehensive evaluation from multiple dimensions when choosing partners. This ensures that they select the most suitable partner for their own needs.

First

Investigate the enterprise’s technical strength and industry experience. Focus on the enterprise’s technical accumulation in precision metal stamping and metal stamping manufacturing fields. For example, whether it has patented technologies, whether it has served well-known enterprises in the industry, and whether it has cases to meet complex needs. At the same time, understand the enterprise’s precision metal fabrication and precision metal machining capabilities. Check whether it has a complete process chain and can provide full-process services from design, stamping, machining to fabrication.

Second

Evaluate the enterprise’s production scale and delivery capabilities. The size of production scale directly affects the enterprise’s order undertaking capacity and delivery cycle. Especially for customers with large-volume procurement needs, it is necessary to confirm whether the enterprise’s metal stamping manufacturing production line has sufficient production capacity. It can complete order delivery within the agreed time. In addition, the enterprise’s supply chain management capability is also crucial. Stable raw material supply and efficient production plan scheduling are key factors to ensure delivery capabilities.

Finally

Pay attention to the enterprise’s quality control system and after-sales service. The quality of precision metal components is directly related to the safety and performance of end products. Therefore, enterprises need to have a sound quality control system. From raw material inspection, production process monitoring to finished product inspection, each link must have strict standards and processes. At the same time, high-quality after-sales service is also indispensable. For example, if there is a quality problem with the product, can the enterprise respond in a timely manner and provide solutions? Can it adjust the production plan in a timely manner according to changes in customer needs?

Choose Vanmodel Sheet Metal to Enjoy Professional Precision Metal Solutions

If you are troubled by choosing a precision metal enterprise, you may consider Vanmodel Sheet Metal. We have many years of experience in precision metal stamping and metal stamping manufacturing. We can provide you with high-precision and high-stability precision metal stamping parts and stamped metal parts. At the same time, we have complete precision metal machining and precision sheet metal fabrication capabilities. We can realize one-stop services from product design, process development to mass production and component assembly to meet your diverse needs.

In terms of technology, we have a professional mold design team and advanced stamping equipment. We can accurately control the precision of precision metal stamping to ensure the consistency of each batch of products. In terms of production management, we realize full-process monitoring of metal stamping manufacturing through the MES system. We can quickly respond to your order needs and shorten the delivery cycle. We use high-precision testing equipment to strictly inspect each product, ensuring compliance with your design standards. For high-precision custom metal stamping needs, our rich industry experience enables exclusive process schemes to solve your technical problems.

Whether you are a new energy enterprise in need of ev metal part stamping or a technology company in need of precision electronic components, Vanmodel Sheet Metal can provide you with professional and reliable precision metal solutions. Contact us now to cooperate with us to jointly improve the competitiveness of your products!

Choose Us! Click for more details

https://vanmodel-sheetmetal.com/wp-admin/post.php?post=2970&action=edit