L'efficacité du prototypage de tôles métalliques réalise de nouvelles percées au Salon international des machines de Shenzhen

At the just-concluded China Shenzhen International Machinery Exhibition, technological innovation and efficiency upgrades in the sheet metal processing field became the focus of attention. Among them, the breakthrough progress of sheet metal prototyping was particularly striking. This breakthrough solves key industry pain points. Traditional sheet metal prototyping has long production cycles. It also has limited precision. Precision sheet metal fabrication serves as core support. This brings new possibilities for downstream manufacturing enterprises. They can achieve cost reduction and efficiency improvement. Exhibition on-site demonstration data has been released. The new solution boosts sheet metal prototyping efficiency by over 40% compared with traditional processes. The qualification rate of precision sheet metal fabrication stabilizes at 99.8%. Aluminum sheet metal suppliers and metal workshop directors at the scene have shown extensive interest. They have launched numerous inquiries.

With Precision Sheet Metal Fabrication as the Core, Laying a Solid Foundation for Efficiency Upgrades

Behind the efficiency breakthrough is the full maturity and in-depth application of precision sheet metal fabrication technology. In the sheet metal processing industry, there is often a balance challenge between precision and efficiency. However, the new solution presented at this exhibition has broken this bottleneck through the collaborative upgrade of software and hardware. At the exhibition site, a well-known enterprise demonstrated a precision sheet metal fabrication production line integrated with AI intelligent planning and automated equipment. It can automatically match the optimal processing parameters according to different sheet metal prototyping needs. Whether it is lightweight prototypes of 6061 sheet metal or high-strength samples of 304 sheet metal, precision sheet metal fabrication can achieve precise control.

For enterprises engaged in sheet metal prototyping, the importance of precision sheet metal fabrication is self-evident. In traditional prototype production, the process of repeatedly adjusting dimensions and correcting errors often takes a lot of time. Through pre-precise modeling and real-time data monitoring, precision sheet metal fabrication controls errors within 0.01mm, reducing rework frequency from the source. As the exhibition technical consultant said: “Today’s precision sheet metal fabrication is no longer a simple processing link, but a core system running through the entire sheet metal prototyping process. It transforms prototype production from ‘trial-and-error’ to ‘precision-based’, which is the key to efficiency breakthroughs.”

At this exhibition, many precision sheet metal fabrication companies brought cases based on new processes. One set of data is impressive: for a battery shell sheet metal prototyping project of a new energy enterprise, the traditional process required 15 days to complete the first sample. Precision sheet metal fabrication technology has been used for optimization. The qualified prototype was completed in just 4 days. The connection efficiency of subsequent mass production also increased by 30%. This case fully proves that precision sheet metal fabrication can not only improve the speed of sheet metal prototyping but also help enterprises open up an efficient channel from prototype to mass production.

Focusing on Sheet Metal Prototyping Pain Points, Technological Innovation Achieves Comprehensive Empowerment

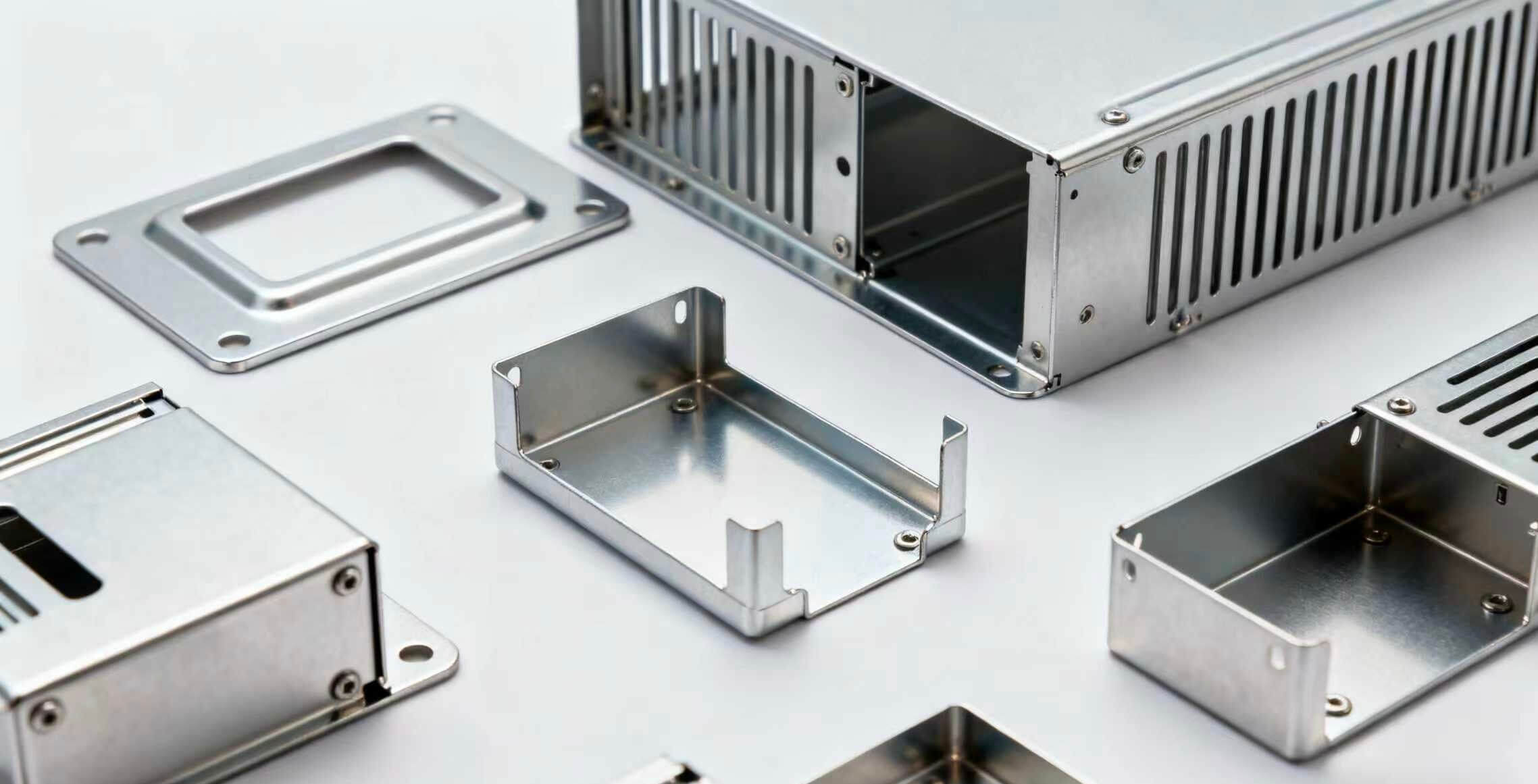

As a key link in product R&D, its efficiency directly affects enterprises’ market response speed. In the past, many enterprises faced various problems in sheet metal prototyping. For example, it was difficult to meet customized needs, the cost of small-batch processing was high, and delivery cycles were uncontrollable. Especially in the prototype production of complex parts, such as custom metal enclosures and custom metal brackets, these pain points are more prominent. The technological breakthroughs at this Shenzhen Machinery Exhibition target these problems directly. They solve the key pain points effectively. Sheet metal prototyping thus achieves three core goals: high efficiency, precision and low cost.

Technological innovation is first reflected in the upgrading of processing equipment. The exhibition displayed a new generation of sheet metal laser cutting equipment. It is combined with custom CNC metal cutting technology. Thus, it can quickly respond to the diverse needs of sheet metal prototyping. Whether it is complex patterns of laser cut steel panels or fine holes in aluminum sheet metal, the equipment can ensure precision. At the same time, it can increase processing speed by more than 50%. This efficient processing capability frees sheet metal prototyping from structural complexity constraints, providing R&D personnel with greater design space.

In addition to equipment upgrades, the application of digital management systems has also provided important support for improving sheet metal prototyping efficiency. Enterprises can establish full-process digital files for sheet metal prototyping. They can track processing progress in real time, monitor quality data, and enable information sharing with subsequent links. These links include custom sheet metal enclosures. As mentioned in “Guide complet du rôle des presses plieuses pneumatiques dans le traitement de la tôle“, digital process management is an effective means to solve the efficiency problem of customized processing, and this concept has been fully reflected in the sheet metal prototyping technology at this exhibition.

In addition, the improvement of material adaptability has expanded the application scope of sheet metal prototyping. The technical solutions displayed at this exhibition can perfectly adapt to various commonly used materials such as 304 sheet metal, 6061 sheet metal, and stainless steel sheet metal, and can even meet the precision processing needs of flat sheet of precious metal. This means efficient solutions are available for diverse needs. For example, aerospace sheet metal fabrication prototypes in the aerospace field. Or small enclosure sheet metal prototyping in the consumer electronics field. A sheet metal specialist at the exhibition shared his view. He said today’s sheet metal prototyping has entered a new era. The era is defined by “full material adaptation and full-process efficiency”. This has injected new vitality into product R&D across various industries.

Industrial Collaboration to Build a New Ecology of Sheet Metal Processing

This China Shenzhen International Machinery Exhibition showcased efficiency breakthroughs. The breakthroughs cover sheet metal prototyping and precision sheet metal fabrication. They are not isolated achievements of a single enterprise. They are the result of collaborative efforts across the entire sheet metal processing industry chain. From high-quality raw materials provided by aluminum sheet metal suppliers to technological innovations of sheet metal machinery enterprises, and process optimization of sheet metal workshops, progress in every link has laid the foundation for the final efficiency breakthrough.

In industrial chain collaboration, precision sheet metal fabrication technology plays a core linking role. It not only connects upstream material supply and equipment manufacturing but also closely integrates with downstream product R&D and mass production. For example, stainless steel sheet metal suppliers respond to the needs of precision sheet metal fabrication. They optimize the flatness and finish of materials. This thus reduces polishing time in subsequent processing. Sheet metal contractors master precision sheet metal fabrication technology. They then improve the delivery quality and efficiency of sheet metal prototyping. This positive interaction between upstream and downstream enterprises is ongoing. It is promoting the sheet metal processing industry to form a more efficient and collaborative industrial ecology.

At the same time, the continuous improvement of industry standards has provided guarantee for technological innovation. At this exhibition, multiple enterprises jointly released the “Precision Sheet Metal Fabrication Quality Control Specifications”, which made a series of clear provisions on the precision standards, processing processes, and testing methods of sheet metal prototyping. This specification is introduced. It will help avoid vicious competition in the industry, and guide enterprises to invest more energy in technological R&D and efficiency improvement. Thus, it promotes the healthy development of the entire industry. For enterprises, carrying out sheet metal prototyping and precision sheet metal fabrication in accordance with unified standards is beneficial. It can not only improve product quality, but also reduce communication costs and improve cooperation efficiency.

Seize Efficiency Dividends and Choose Professional Partners to Start a New Journey

The technological breakthroughs at the China Shenzhen International Machinery Exhibition have brought unprecedented development opportunities to the sheet metal processing industry. For enterprises engaged in product R&D, seizing the efficiency dividends of sheet metal prototyping and precision sheet metal fabrication is crucial. Choosing professional partners is also crucial. Professional sheet metal processing enterprises have mature precision sheet metal fabrication technology. Moreover, they can provide one-stop solutions according to the specific needs of enterprises. The solutions cover from prototype design to mass production.

When choosing a partner, enterprises can focus on their sheet metal prototyping case experience, precision sheet metal fabrication equipment strength, and industrial chain resource integration capabilities. As emphasized in “Comment choisir une usine de tôlerie de précision ? Voici les points clés.“, enterprises with strong comprehensive strength can provide customers with stable and efficient services. Taking the outstanding enterprises at this exhibition as examples, they not only have advanced laser cutting and CNC processing equipment but also have established a sound supply chain system. They can quickly allocate raw materials such as 304 sheet metal and 6061 sheet metal to ensure the timely delivery of sheet metal prototyping.

Are you troubled by sheet metal prototyping efficiency? Or do you need high-quality precision sheet metal fabrication services? Feel free to contact vanmodel sheet metal immediately. We have years of industry experience, and we master the latest sheet metal processing technology. Therefore, we can provide you with efficient and precise customized solutions. These solutions help your products quickly seize market opportunities. Whether it is prototype production of custom sheet metal enclosures or small-batch processing of custom metal brackets, we can meet your needs with professional services. Let’s win the new era of the sheet metal processing industry hand in hand.