Laser Cutting

描述

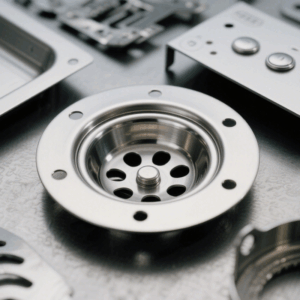

Precision Laser Cutting Services for Industrial & Creative Applications

Laser cutting represents an advanced manufacturing technology that employs high-power lasers guided by precision optics and computer numerical control (CNC) systems. This sophisticated process utilizes a motion control system that accurately follows CNC or G-code patterns to cut intricate designs into various materials with exceptional precision.

Key Process Advantages:

-

Exceptional Precision – Achieve intricate designs and tight tolerances with clean, sharp edges

-

Versatile Material Compatibility – Process metals, plastics, wood, acrylics, and composites

-

Superior Edge Quality – Obtain smooth, finished edges without secondary processing

-

High Efficiency – Rapid cutting speeds with minimal material waste

-

Complex Geometry Capability – Execute intricate patterns and detailed designs effortlessly

Our Laser Cutting Capabilities:

-

CNC-controlled laser systems with precision optics

-

Multi-axis cutting for complex three-dimensional components

-

High-speed processing for production volumes

-

Fine detail etching and engraving services

-

Custom programming for unique design requirements

Quality & Precision Assurance:

Each project undergoes stringent quality checks to ensure dimensional accuracy, edge quality, and adherence to specified tolerances, guaranteeing consistent results across all production runs.

Industry Applications:

-

Industrial component manufacturing

-

Architectural metalwork and signage

-

Automotive and aerospace parts

-

Electronic enclosures and panels

-

Custom artistic installations and displays

-

Prototype development and rapid manufacturing

Advanced Technical Features:

-

Automated material handling systems

-

Real-time monitoring and calibration

-

CAD/CAM integration for seamless workflow

-

Gas-assisted cutting for optimal edge quality

Start Your Laser Cutting Project:

[Request Instant Quotation] or [Consult Our Technical Team]