Showing 1–12 of 14 results

-

Precision Sheet Metal Bending Services for Industrial Applications Our specialized metal forming services utilize advanced equipment to create precise V-shapes, U-shapes, and channel profiles in ductile materials. Through our bending processes involving CNC press brakes and precision machinery, we transform flat sheets into accurately formed components while maintaining consistent quality and dimensional accuracy. Key Service…

-

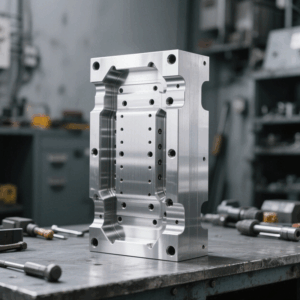

Precision CNC Machining: Advanced Manufacturing Solutions for Demanding Industries CNC machining represents a sophisticated approach to modern manufacturing, where pre-programmed computer software directs industrial equipment with exceptional accuracy. Specifically, this technology operates diverse machinery—from precision grinders and lathes to advanced mills and routers—executing complex three-dimensional cutting tasks through optimized command sequences. Key Advantages of Our CNC Machining…

-

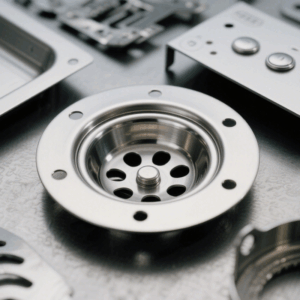

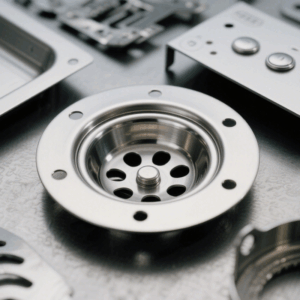

Precision Deep Drawing Services for Complex Metal Components Deep drawing represents an advanced sheet metal forming process where a metal blank is radially drawn into a forming die through the precise mechanical action of a punch. This sophisticated shape transformation technique maintains material integrity while creating deep, seamless components. The process qualifies as “deep drawing”…

-

Precision Sheet Metal Fabrication, Tailored to Your Vision At VanModel, we bridge the gap between your concepts and high-quality, durable sheet metal products. Specifically, our flexible manufacturing processes seamlessly integrate custom mold stamping and precision laser cutting, ensuring your project—from single prototypes to high-volume production runs—is executed with exceptional efficiency and accuracy. Our Commitment to Excellence: Unmatched…

-

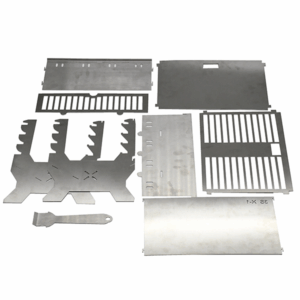

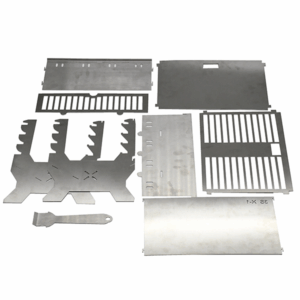

Precision Laser Cutting Services for Industrial & Creative Applications Laser cutting represents an advanced manufacturing technology that employs high-power lasers guided by precision optics and computer numerical control (CNC) systems. This sophisticated process utilizes a motion control system that accurately follows CNC or G-code patterns to cut intricate designs into various materials with exceptional precision….

-

What Is Welding? Welding is a specialized process that joins two pieces of metal together by melting and fusing them. Unlike fabrication, which covers a broader range of activities, welding specifically deals with bonding materials to create a unified structure. There are many welding techniques, each serving unique purposes. MIG (metal inert gas) welding is…

-

Metal Spinning Services: Precision-Formed Components for Demanding Industries Metal spinning services—also called spin forming or metal turning—deliver highly versatile and cost-effective solutions for producing precision symmetric components. This efficient metal forming process transforms flat metal discs or tubes into accurately formed, axially symmetric parts through controlled pressure application during high-speed rotation. Thanks to its inherent…

-

What is Metal Stamping? Metal stamping is a high-volume, high-efficiency manufacturing process that transforms flat sheet metal (steel, aluminum, brass, etc.) into precise, complex components. Using specialized tooling called stamping dies and powerful presses, the process performs cutting, bending, punching, embossing, and forming in rapid succession – often completing parts in seconds. Why Industries Rely on Stamping:…

-

Precision Metal Stamping for Industrial Manufacturing Metal stamping is an advanced cold-forming process that utilizes precision-engineered dies and stamping presses to create complex, high-quality components. This efficient method processes flat sheet metal blanks using specialized equipment, reshaping materials into precise configurations with exceptional accuracy. Key Advantages: • Cost Efficiency – Ideal for high-volume production with reduced per-unit…

-

Precision Sheet Metal Fabrication: Your Vision, Our Craftsmanship At the core of our service is a commitment to transforming your concepts into durable, high-quality sheet metal products. Specifically, we achieve this through flexible manufacturing processes that seamlessly integrate custom mold stamping with precision laser cutting. As a result, whether you require a single prototype or…

-

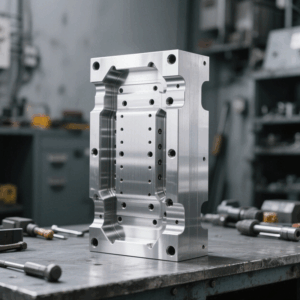

Precision Metal Molds: Engineered for Excellence in High-Volume Production At the heart of every flawlessly manufactured component lies a masterfully crafted precision metal mold. Indeed, more than just a tool, it serves as the cornerstone of your production line, directly determining final product quality, manufacturing efficiency, and per-part cost. Accordingly, VanModel specializes in designing and building these high-performance molds—the…

-

Sheet Metal Fabrication Services – Precision Metal Manufacturing Solutions Sheet metal fabrication is a comprehensive manufacturing process that transforms raw metal sheets into precisely formed components through specialized techniques. This sophisticated process typically involves multiple crucial stages – beginning with precision cutting and CNC bending, progressing through professional surface treatment, and concluding with accurate assembly….