Стратегии ценообразования и советы по гарантированию прибыли при импорте и экспорте штампованных металлических деталей.

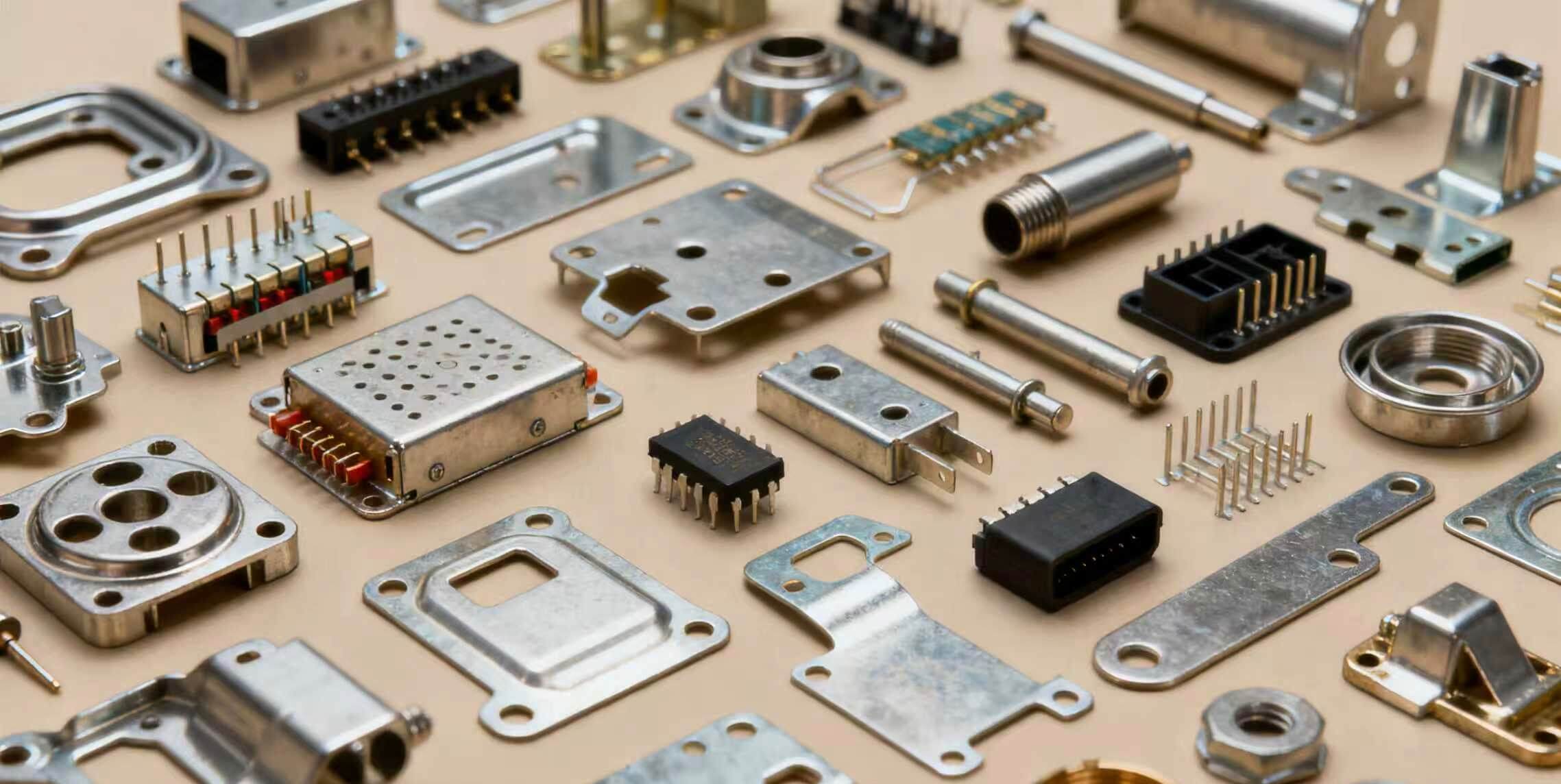

В современную эпоху глубокой интеграции в глобальном производстве, штампованные металлические детали, являющиеся основными компонентами в машиностроении, автомобилестроении, электронике и других областях, демонстрируют устойчивый рост объемов импорта и экспорта. Для предприятий, занимающихся высокоточной штамповкой металла, научно обоснованные стратегии ценообразования являются не только ключом к выходу на международные рынки, но и основной линией защиты для обеспечения стабильной прибыли. В данной статье будет рассмотрена логика ценообразования при импорте и экспорте штампованных металлических деталей с таких точек зрения, как исследование рынка, учет затрат, методы ценообразования и контроль рисков, а также будут предложены практические советы по обеспечению прибыли, которые помогут предприятиям получить конкурентное преимущество на международном рынке.

I. Закрепление ключевых сегментов рынка: спрос и конкурентная среда в сфере прецизионной штамповки металлов.

Точное понимание рынка является необходимым условием ценообразования. Особенно для технологически сложных продуктов, таких как прецизионная штамповка металла, рыночный спрос и динамика конкуренции напрямую определяют ценовой диапазон.

Сегментация спроса: Различные требования на разных рынках

Со стороны спроса, высокотехнологичные производственные отрасли в Европе и США предъявляют строгие требования к точности и долговечности деталей, изготовленных методом прецизионной штамповки металла. В отличие от них, развивающиеся рынки, такие как Юго-Восточная Азия и Южная Америка, больше ориентированы на экономическую эффективность. В результате, ценовая политика на этих двух типах рынков значительно различается.

Например, при поставке металлических штампованных деталей для электромобилей европейским автомобильным предприятиям необходимо в полной мере учитывать техническую добавленную стоимость, принимая во внимание строгие стандарты безопасности и охраны окружающей среды. С другой стороны, при поставке обычных металлических штампованных деталей на заводы по сборке электроники в Юго-Восточной Азии следует подчеркивать ценовые преимущества за счет строгого контроля затрат.

Конкурентная среда: глобальная структура и позиционирование предприятия.

С точки зрения конкурентной среды, мировые производители в секторе металлообработки в настоящее время демонстрируют модель «концентрации в сегменте высокого класса и фрагментации в сегменте среднего и низкого ценового сегмента». Европейские и американские предприятия доминируют в сфере услуг по изготовлению прецизионных деталей на заказ благодаря технологическим преимуществам. В отличие от них, китайские предприятия обладают конкурентоспособностью в крупномасштабном производстве прецизионных компонентов благодаря полной производственной цепочке. Перед установлением цен предприятиям необходимо уточнить свою конкурентную позицию на целевых рынках. Они могут сделать это с помощью отраслевых отчетов, выставок и других каналов, а затем решить, следует ли им создавать бренд высокого класса с помощью технологий прецизионной обработки или завоевывать рынок среднего и низкого ценового сегмента за счет экономически эффективной стратегии. Это решение напрямую определит дальнейшие направления ценообразования. Между тем, подробный анализ статьи Индивидуальная штамповка металла для высокой точности: решение проблем штамповки металлических деталей электромобилей Это может помочь предприятиям лучше понять болевые точки спроса на рынках товаров премиум-класса, что позволит привести ценообразование в соответствие с ожиданиями клиентов.

II. Учет затрат: краеугольный камень ценообразования штампованных металлических деталей.

Стоимость — это определяющий фактор ценообразования. Импортные и экспортные издержки на штампованные металлические детали включают в себя множество звеньев, в том числе производство, логистику и таможенные пошлины — любая ошибка на любом из этих звеньев может привести к снижению прибыли.

Основные производственные затраты: сырье, переработка и рабочая сила.

Производственные затраты являются основными и включают в себя сырье, обработку, рабочую силу и амортизацию оборудования. В качестве примера рассмотрим прецизионные изделия из металла, изготовленные методом штамповки. Высокопрочные сплавы стоят более чем на 301 тыс. тонн дороже обычной стали. С другой стороны, многостанционная технология непрерывной штамповки имеет вдвое большую эффективность обработки по сравнению с традиционными процессами. Хотя эта технология требует больших инвестиций в оборудование, она позволяет сократить удельные издержки обработки на 151 тыс. тонн. Все эти детали должны быть учтены в калькуляции затрат.

Невидимые издержки: логистика, тарифы и дополнительные расходы.

Логистические и таможенные издержки являются невидимыми пороговыми значениями для импортно-экспортных компаний. Морские перевозки дешевы, но медленны, и сопряжены с дополнительными затратами на складские запасы. Авиаперевозки быстры, но дороги, идеально подходят для дорогостоящей продукции, такой как высокоточные детали из металла, изготовленные методом штамповки на заказ.

Предприятиям необходимо заранее изучить тарифную политику стран-целей. Например, китайские детали, изготовленные методом штамповки, экспортируемые в страны АСЕАН, пользуются льготными тарифами в рамках RCEP, что увеличивает прибыль или позволяет предлагать более низкие цены. Необходимо заранее оценить затраты на страхование, таможенное оформление и обменный курс. Тщательный и отслеживаемый учет затрат на штампованные детали является ключом к установлению разумных цен.

III. Научные методы ценообразования: основная логика баланса между конкурентоспособностью и прибылью

Исходя из рыночного спроса и ценовых показателей, предприятия, занимающиеся точной штамповкой металла, могут применять различные методы ценообразования, гибко реагируя на различные сценарии импорта и экспорта.

Ценообразование по принципу «затраты плюс прибыль»: для высокотехнологичных барьерных изделий.

Для услуг по изготовлению прецизионных металлических штампованных изделий на заказ, характеризующихся высокими техническими барьерами, может быть применен метод ценообразования «себестоимость плюс прибыль» — добавление разумной наценки (обычно 151-301 тыс. рупий) сверх покрытия всех затрат. Этот метод подходит для эксклюзивных или дефицитных продуктов. Например, прецизионные металлические штампованные детали для конкретного медицинского оборудования имеют низкую ценовую чувствительность клиентов из-за технической эксклюзивности, и стабильная прибыль может быть гарантирована за счет ценообразования «себестоимость плюс прибыль».

Ценообразование, ориентированное на конкуренцию: для обычных товаров-конкурентов

Для обычных штампованных металлических деталей на высококонкурентных рынках более целесообразно ценообразование, ориентированное на конкуренцию. Предприятиям необходимо изучать предложения основных конкурентов, комбинировать собственные преимущества в затратах для установления цен немного ниже, чем у конкурентов, или поддерживать ценовую конкурентоспособность за счет предоставления дополнительных услуг (таких как бесплатное тестирование и послепродажное обслуживание). Например, на рынке Юго-Восточной Азии китайские предприятия могут продавать штампованные металлические детали по ценам в 701-801 тыс. тонн ниже, чем европейские и американские предприятия, используя преимущества производственной цепочки и обещая более короткие сроки поставки для завоевания доли рынка.

Многоуровневое ценообразование и динамическая корректировка

Для крупных долгосрочных клиентов в рамках кооператива применяется многоуровневое ценообразование — скидки предоставляются в зависимости от объема закупок, что стабилизирует партнерские отношения и снижает удельные издержки за счет эффекта масштаба. На практике предприятия могут использовать методологию, описанную в [ссылка на методологию]. Как удвоить эффективность производства штамповки металлических изделий на заказ? для оптимизации производственных процессов, дальнейшего снижения затрат и расширения ценовой гибкости.

Следует отметить, что цены на прецизионные изделия из металла, изготовленные методом штамповки, не являются фиксированными. При резких колебаниях цен на сырье, корректировке тарифной политики стран-получателей или внезапных изменениях рыночного спроса предприятиям необходимо оперативно корректировать свои ценовые стратегии. Возьмем, к примеру, колебания цен на сталь: если цены на сталь недавно выросли на 101 тыс. тонн, предприятия могут предоставить клиентам отчеты о себестоимости и умеренно повысить цены на штампованные металлические детали. При этом они могут частично снизить издержки за счет оптимизации производственного процесса, тем самым уравновешивая интересы как предложения, так и спроса.

IV. Советы по гарантированию прибыли: от контроля рисков до повышения ценности

Ценообразование — это лишь отправная точка. Обеспечение прибыльности в импортно-экспортном бизнесе штампованных металлических деталей также требует комплексных стратегий контроля рисков и повышения добавленной стоимости.

Управление рисками: снижение валютных и качественных рисков

Валютный риск представляет серьезную проблему для импортеров и экспортеров. Компании могут зафиксировать такие риски с помощью форвардных валютных контрактов или инструментов хеджирования валютного риска, предотвращая потери дохода от обесценивания валюты. Например, компания, экспортирующая прецизионные металлические штампованные детали в США, договорилась об обменном курсе 6,9 на 3-месячный срок расчетов. Даже если курс упадет до 7,2, компания все равно сможет получить оплату по согласованному курсу, обеспечив себе стабильную прибыль.

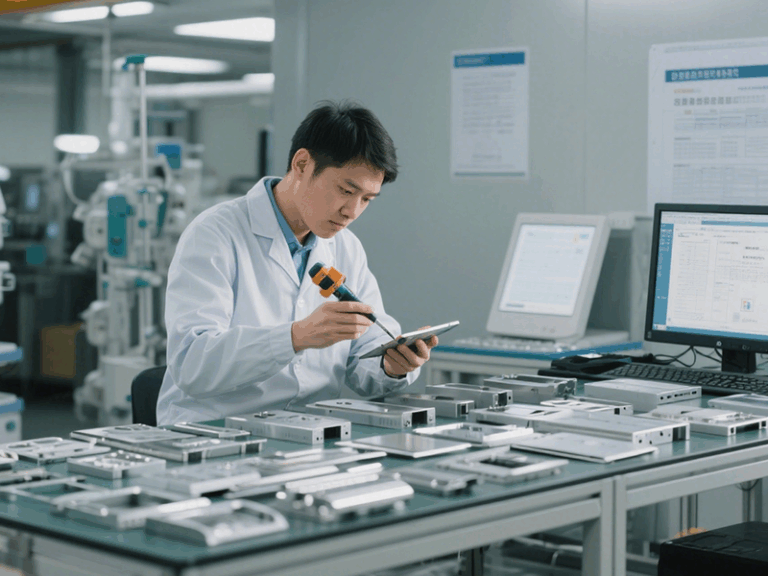

Контроль качества — это жизненно важный фактор, гарантирующий прибыль. Изделия, изготовленные методом высокоточной штамповки металла, требуют высокой точности: проблемы с качеством приводят к возвратам и доработкам, увеличению затрат и ухудшению репутации. Предприятия должны создать систему контроля качества полного цикла, контролирующую закупку сырья, производственные процессы и тестирование готовой продукции. Использование профессиональных рекомендаций по контролю качества позволяет предотвратить проблемы на ранней стадии, избегая снижения прибыли.

Повышение ценности: от обработки данных до интегрированных услуг.

Повышение добавленной стоимости продукции — эффективный способ увеличения прибыли. Предприятия могут трансформироваться из «переработчиков» в «поставщиков услуг», предлагая клиентам комплексные услуги по высокоточной штамповке металла на заказ, включая полный цикл услуг, таких как проектирование продукции, разработка пресс-форм, серийное производство и логистическая дистрибуция. Например, предоставляя услуги по штамповке металлических деталей для электромобилей предприятиям, занимающимся разработкой новых энергетических транспортных средств, они могут участвовать в ранних этапах проектирования продукции, предлагать варианты оптимизации для снижения общих затрат клиентов и, таким образом, получать большую ценовую власть. Кроме того, предприятия могут модернизировать технологии высокоточной штамповки металла за счет инноваций. Таким образом, они могут разрабатывать более легкие и прочные штампованные металлические детали. Такой подход может значительно повысить добавленную стоимость продукции и рентабельность.

V. Заключение: Точная компоновка для завоевания международного рынка штампованных металлических деталей.

В сфере импорта и экспорта штампованных металлических деталей ценовые стратегии являются ключевым звеном, связывающим рынки и прибыль. В то же время, гарантия прибыли опирается на многостороннюю поддержку, включающую контроль затрат, предотвращение рисков и повышение ценности. Для предприятий, занимающихся высокоточной штамповкой металла, только точное исследование рыночного спроса, точный учет затрат и гибкое применение методов ценообразования позволят им занять прочное положение в условиях жесткой международной конкуренции.

Если у вас есть вопросы о ценах на импорт и экспорт штампованных металлических деталей, применении технологии прецизионной штамповки металла или вам необходимы индивидуальные решения по штамповке металла, пожалуйста, немедленно свяжитесь с компанией Vanmodel Sheet Metal. Благодаря профессиональному опыту и передовым технологиям мы поможем вам добиться роста прибыли и расширения бизнеса на мировом рынке.