Разборка процесса изготовления прецизионных изделий из листового металла

In modern industrial manufacturing, precision sheet metal fabrication stands as a crucial core process. It boasts advantages of high precision and high flexibility. It is widely applied in many industries such as electronic equipment, medical devices and automotive parts. The complete process of precision sheet metal fab connects every key link from design drawings to final finished products. Among them, sheet metal laser cutting and custom cnc metal cutting, as core processing steps, directly determine the precision and quality of products. This article will detail the entire process of precision sheet metal fab processing. It will take you to deeply understand every key action from drawing analysis to finished product delivery.

Preliminary Preparation: Drawing Analysis and Material Selection to Lay the Foundation for Precision Sheet Metal Fabrication

Any successful precision sheet metal fab processing starts with rigorous preliminary preparation work. The core tasks at this stage are to convert the product design drawings provided by customers into executable processing plans. At the same time, complete the selection of appropriate sheet metal materials to lay a solid foundation for subsequent processing links.

First is the drawing analysis link. Engineers will use professional CAD software to carefully disassemble the product drawings. They clarify key parameters such as product dimensional tolerance, structural complexity, bending angle and hole distribution. These parameters will determine the processing path of subsequent sheet metal laser cutting and custom cnc metal cutting. For example, if the drawing requires the product to have multiple special-shaped holes with a tolerance of ±0.05mm, engineers need to plan the laser cutting path and CNC machining tool selection in advance to ensure every detail meets the design standards.

Second is material selection. Different industries have distinct performance requirements for sheet metal materials, so manufacturers must choose the most suitable options based on the product’s use scenarios and functional needs. Common choices include aluminum sheet metal, 304 sheet metal, and 6061 sheet metal. 304 sheet metal offers excellent corrosion resistance, making it ideal for rust-prone scenarios like food machinery and medical devices. 6061 sheet metal has good strength and processability, widely used for electronic equipment enclosures and automotive parts. Aluminum sheet metal is lightweight with strong thermal conductivity, commonly applied in aerospace and communication equipment. During selection, close communication with aluminum and stainless steel sheet metal suppliers is maintained to ensure stable quality of purchased sheets, laying a solid raw material foundation for precision sheet metal fabrication.

Core Processing Step 1: Sheet Metal Laser Cutting to Achieve High-Precision Material Cutting

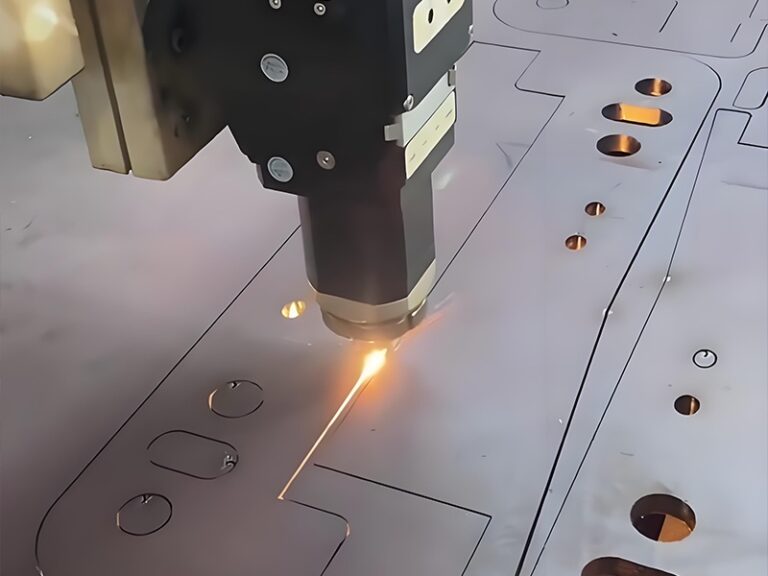

After the preliminary preparation, the precision sheet metal fab processing enters the core link – sheet metal laser cutting. As the current mainstream sheet metal cutting technology, sheet metal laser cutting has a series of advantages such as high cutting precision, fast speed and smooth cuts. It can easily meet customers’ various complex shape cutting needs. It is a key means to realize custom cut metal and custom cut metals.

Before performing sheet metal laser cutting operations, technicians will first import the analyzed drawing data into the control system of the laser cutting equipment. They set cutting parameters, including laser power, cutting speed, gas type (such as oxygen for carbon steel cutting, nitrogen for stainless steel cutting to avoid oxidation), etc. Then, the selected sheet metal plate is fixed on the cutting workbench. The equipment will start cutting according to the preset path. Throughout the process, the laser beam is like a “precision scalpel”. It can accurately cut various shapes of workpieces on the sheet metal plate. Whether it is straight lines, curves or special-shaped holes, it can achieve a cutting tolerance of ±0.03mm. This fully meets the high-precision requirements of precision sheet metal fabrication.

For example, when a customer needs to customize a batch of custom metal brackets, we will use sheet metal laser cutting technology to cut 304 sheet metal or aluminum sheet metal plates into the basic shape of the bracket. We first ensure that the hole positions and edge dimensions of the bracket are completely consistent with the drawings. Sheet metal laser cutting outperforms traditional mechanical cutting methods. It avoids precision errors caused by tool wear. It also greatly improves cutting efficiency. The advantages are more obvious for batch processing of products such as custom metal plates and laser cut steel panels. In our metal workshop, sheet metal laser cutting equipment can process hundreds of sheet metal plates of different specifications every day. It provides high-quality semi-finished products for the subsequent CNC processing link.

Core Processing Step 2: Custom CNC Metal Cutting to Complete Fine Structure Processing

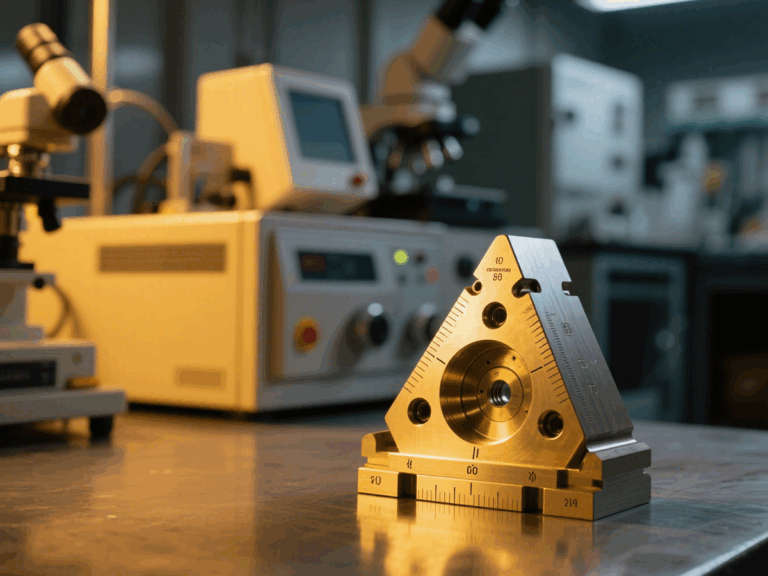

The semi-finished products obtained after sheet metal laser cutting often require further fine processing to meet product requirements. Custom cnc metal cutting is the core process at this stage. Custom cnc metal cutting uses computer numerical control technology. It can realize complex processing actions such as drilling, tapping and milling on sheet metal workpieces. It accurately completes the processing requirements for detailed structures in precision sheet metal fab.

Before custom CNC metal cutting operations, technicians create exclusive CNC processing programs. These programs are based on the detailed requirements of product drawings. If the workpiece requires drilling and tapping at specific positions, the program specifies key parameters. It includes hole diameter and depth, as well as tapping specifications and rotation speed.Then, the semi-finished product after laser cutting is fixed on the fixture of the CNC machining center. The equipment will automatically complete the processing actions according to the program instructions. Due to the repeat positioning accuracy of CNC equipment up to ±0.005mm, it can ensure that the processing precision of each workpiece is highly consistent. This fully meets the mass production needs of precision sheet metal fabrication.

Take custom sheet metal enclosure processing as an example. Laser cutting completes the enclosure’s overall contour. Custom CNC metal cutting is then used. It processes holes for installing interfaces and screws on the enclosure. Some holes are tapped to ensure the smooth progress of the subsequent assembly link. In addition, for products such as custom metal enclosures that require structural strength, custom cnc metal cutting can also perform chamfering and deburring on the edges of the workpiece through milling processes. This improves the safety and appearance of the product. In our sheet metal workshop, custom cnc metal cutting equipment and sheet metal laser cutting equipment work together to form an efficient collaborative precision sheet metal processing line.

Subsequent Processing: Bending, Welding and Surface Treatment to Shape the Finished Product Form

After completing the two core processing steps of sheet metal laser cutting and custom cnc metal cutting, the precision sheet metal fab process enters the subsequent processing stage. It mainly includes bending, welding and surface treatment. These steps directly determine the final form and service performance of the product.

Shaping from Plane to Three-Dimensional Structure

The bending link is mainly completed through jet sheet metal brake. Technicians will adjust the mold and pressure parameters of the bending machine according to the bending angle and bending sequence required by the drawings. They bend the flat sheet metal workpiece into the required three-dimensional structure. Bending is a key step in sheet metal processing. Examples include bending custom metal plates into right-angle structures for custom metal brackets. It also involves bending laser-cut steel panels into box shapes for custom metal enclosures. During the bending process, strict control of bending precision is essential. This avoids subsequent assembly difficulties caused by angle deviations. This is also a strict requirement of precision sheet metal fabrication for process details.

Integral Splicing and Fusion of Multiple Components

The welding link is used to splice multiple sheet metal components into a complete product. Technicians will select an appropriate welding method (such as argon arc welding, spot welding, etc.) according to the type of material to ensure the strength and sealing of the welding joint. For example, when processing custom metal enclosures, we splice each panel of the enclosure into a whole through welding. We then grind the welds to ensure a flat and smooth appearance.

Dual Improvement of Performance and Appearance

The surface treatment link is also crucial to improve product performance and appearance. Common surface treatment methods include spraying, electroplating, wire drawing, anodizing, etc. To enhance corrosion and wear resistance, anodizing is a common choice for aluminum sheet metal products. 304 sheet metal products, on the other hand, can undergo wire drawing treatment to achieve a more textured visual effect. For custom sheet metal enclosures that demand specific colors, electrostatic spraying technology is employed to guarantee the coating’s uniformity and strong adhesion. In addition, to address possible metal sheet door rust problems, we will add an anti-rust coating during the surface treatment link to extend the service life of the product.

Quality Inspection and Finished Product Delivery: Control the Last Pass of Precision Sheet Metal Fabrication

Throughout the entire process of precision sheet metal fab, quality inspection runs through. After all processing steps are completed, we will also conduct a final finished product inspection to ensure that the products delivered to customers fully meet the requirements.

The finished product inspection link mainly includes dimensional inspection and performance inspection. For dimensional inspection, we use high-precision inspection equipment to measure the key dimensions of the product one by one. It verifies whether they meet the tolerance requirements of the drawings. We effectively guarantee the processing precision of sheet metal laser cutting and custom CNC metal cutting. For performance inspection, we conduct strength, sealing, corrosion resistance and other tests based on the product’s usage scenarios. For example, we perform load-bearing testing on custom metal brackets and waterproof testing on custom metal enclosures.

Only products that pass all quality inspection items can enter the finished product delivery link. We will provide professional packaging and logistics services according to customer needs to ensure that the products are delivered safely and on time. In addition, as a professional precision sheet metal fabricator, we also provide customers with comprehensive after-sales support. We answer questions during subsequent use to help customers achieve efficient application of products.

Contact Vanmodel Sheet Metal Immediately to Start Your Precision Sheet Metal Processing Cooperation

Whether you need laser cut steel panels processed by sheet metal laser cutting, custom metal brackets processed by custom CNC metal cutting, or complete precision sheet metal fabrication solutions, Vanmodel Sheet Metal delivers. Leveraging professional technology, advanced equipment and rich experience, we deliver high-quality products and services tailored to your needs. Our facilities include a modern metal workshop and a dedicated sheet metal workshop, ensuring efficient production capabilities. With long-term partnerships with top-tier aluminum and stainless steel sheet metal suppliers, we can swiftly respond to customized demands—from custom cut metal to custom sheet metal enclosures.

Синергия прецизионной штамповки и обработки металла: открытие новых возможностей

If you are looking for reliable precision sheet metal fabrication companies, please contact Vanmodel Sheet Metal immediately. Our engineers will provide you with one-on-one scheme design. They will control every link of precision sheet metal fab to ensure that every step of your product from drawing to finished product is accurate. We look forward to cooperating with you to jointly create high-quality precision sheet metal products!