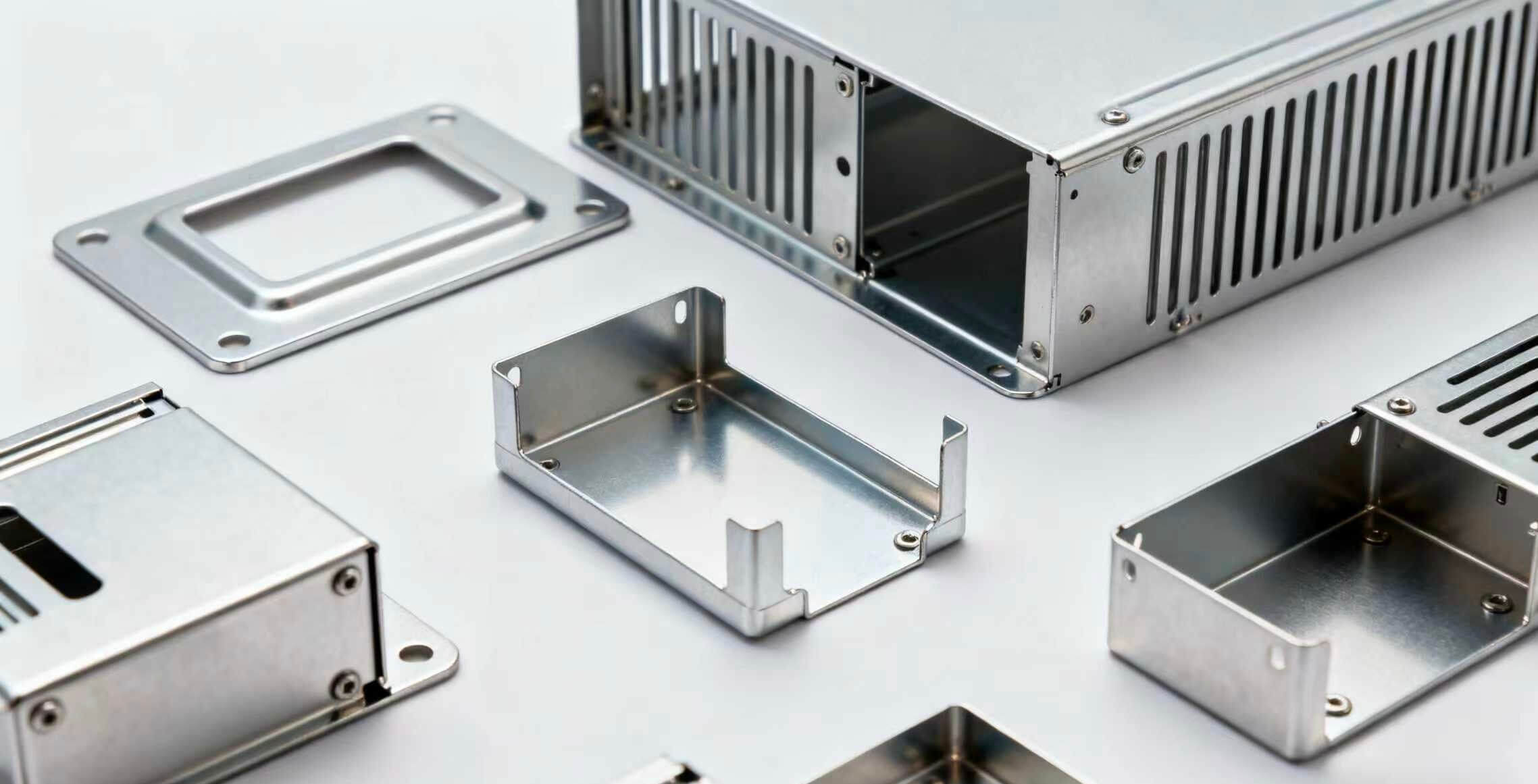

Основные методы прецизионной штамповки металла для стали и алюминия.

В высокоточной металлообработке эффективность и точность имеют ключевое значение. Высокоточная штамповка металла отвечает этим требованиям. Она стала неотъемлемым процессом во многих отраслях промышленности. Сталь и алюминий — два наиболее распространенных основных материала. Их физические свойства сильно различаются. Эти различия напрямую влияют на то, как адаптируется процесс высокоточной штамповки металла. Детали, изготовленные методом высокоточной штамповки металла, можно найти повсюду. Они используются в автомобильных компонентах, электронике и энергетическом оборудовании. Освоение технологий работы с этими материалами имеет жизненно важное значение. Это напрямую влияет на качество продукции и скорость производства. Эта статья начинается с характеристик материалов. В ней будут проанализированы основные различия между сталью и алюминием. Наша цель — предоставить практические технические рекомендации для специалистов отрасли.

I. Сначала характеристики материалов: основа совместимости при штамповке.

Перед началом прецизионной штамповки металла необходимо точно определить характеристики материала. Высокая прочность и ударная вязкость стали обеспечивают ее стабильность при штамповочных нагрузках, но также предъявляют более высокие требования к твердости пресс-формы и усилию штамповки. С другой стороны, алюминий обладает низкой плотностью и хорошей теплопроводностью. Детали, изготовленные методом прецизионной штамповки из алюминия, имеют высокое качество поверхности после формовки, но из-за своей высокой пластичности подвержены проблемам упругого восстановления. Эти различия в характеристиках напрямую приводят к существенным отличиям в производственных процессах изготовления прецизионных деталей методом штамповки металла.

Вот исправленный абзац, сокращенный для удобства чтения, но с сохранением ссылки на статью:

- При штамповке стали следует уделять особое внимание пределу прочности на растяжение и пределу текучести. Низкоуглеродистая сталь широко используется в прецизионной штамповке металлов благодаря своей хорошей пластичности. Она подходит для изготовления сложных деталей методом прецизионной штамповки. Высокоуглеродистая сталь прочнее, но хрупкая. Необходимо контролировать скорость штамповки и зазоры в пресс-форме, чтобы предотвратить образование трещин.

- Что касается алюминия, то чистый алюминий мягкий и используется для изготовления легких деталей. В алюминиевые сплавы добавляют магний и кремний. Это повышает прочность штампованных металлических деталей для электромобилей.

В процессе реального производства следует руководствоваться стандартами проверки качества материалов, изложенными в разделе «Ищем мелкосерийное изготовление листового металла на заказЭто еще больше повышает точность выбора базового материала.

II. Оптимизация пресс-форм: основная гарантия качества.

Пресс-форма является основным оборудованием для прецизионной штамповки металла. Оптимизация конструкции пресс-формы с учетом характеристик стали и алюминия является ключом к повышению точности деталей, изготовленных методом прецизионной штамповки металла. Для стальных штамповочных пресс-форм необходимо использовать высокопрочную инструментальную сталь, например, Cr12MoV, и применять закалку для повышения твердости пресс-формы, чтобы предотвратить ее износ при многократной штамповке. Точность установки зазора в пресс-форме также должна быть обеспечена, обычно он контролируется в пределах от 51 до 101 тонны на 3 тонны толщины материала. Если зазор слишком мал, он может легко поцарапать поверхность заготовки; если он слишком велик, появятся заусенцы, что повлияет на точность деталей, изготовленных методом прецизионной штамповки металла.

Основная задача оптимизации штамповочных пресс-форм для алюминия — снижение трения и контроль упругого восстановления. Поскольку алюминий склонен к прилипанию к поверхности пресс-формы, для снижения коэффициента трения необходимо наносить на рабочую поверхность пресс-формы азотирование или износостойкие покрытия. Алюминий имеет тенденцию к упругому восстановлению. Для решения этой проблемы используются методы предварительной гибки. В качестве альтернативы, можно спроектировать пресс-форму с встроенной компенсацией упругого восстановления. Это гарантирует соответствие заготовки заданным размерам после прецизионной штамповки металла. Такое же внимание к деталям относится и к направляющему механизму пресс-формы. Он должен быть высокоточным. Это справедливо как для штамповки стали, так и для штамповки алюминия. Высокая точность предотвращает отклонения в процессе. Это особенно важно для услуг по прецизионной штамповке металла на заказ. В конечном итоге, это гарантирует точность размеров ваших деталей, изготовленных методом прецизионной штамповки металла на заказ.

III. Управление параметрами процесса: ключевые настройки для различных базовых материалов

Точная настройка параметров процесса является ключевым звеном в успешной прецизионной штамповке металла. Характерные различия между сталью и алюминием определяют, что направления регулировки параметров для них совершенно разные.

Оптимизация технологических процессов для различных материалов

- Скорость штамповки: При штамповке стали скорость необходимо регулировать в зависимости от марки стали. Для низкоуглеродистой стали можно использовать более высокую скорость штамповки для повышения эффективности, в то время как для высокоуглеродистой стали требуется более низкая скорость, чтобы избежать разрушения материала из-за чрезмерного удара. Скорость штамповки алюминия может быть немного выше, но ее необходимо контролировать в разумных пределах, чтобы предотвратить неравномерную деформацию из-за чрезмерной скорости, которая влияет на качество поверхности прецизионных металлических штампованных деталей.

- Сила штамповки: Контроль имеет не меньшее значение. Высокая прочность стали требует от штамповочного оборудования достаточной грузоподъемности. Например, при обработке стальных пластин толщиной 5 мм необходимо выбирать штамповочное оборудование с усилием более 1000 кН, чтобы обеспечить полную форму материала. Усилие штамповки алюминия относительно меньше, при этом основное внимание уделяется равномерной передаче усилия во избежание вмятин на заготовке, вызванных чрезмерным локальным усилием.

- Смазка: Выбор процесса смазки нельзя игнорировать. Для штамповки стали можно использовать смазки на масляной основе для улучшения смазки и защиты пресс-формы. Для штамповки алюминия производители должны выбирать водорастворимые смазки, чтобы предотвратить образование остатков, влияющих на последующую обработку поверхности. Эти методы настройки параметров особенно важны при штамповке металла на заказ для высокоточных применений и являются ключевыми элементами обеспечения качества продукции.

Комплексная система управления качеством для стали и алюминия

Контроль качества осуществляется на протяжении всего процесса прецизионной штамповки металла. Для деталей из стали, изготовленных методом штамповки, основное внимание следует уделять проверке механических свойств, таких как прочность на растяжение и твердость, чтобы гарантировать соответствие требованиям эксплуатации. Для деталей из алюминия, изготовленных методом штамповки, необходимо уделять пристальное внимание двум основным факторам. Во-первых, точности размеров. Во-вторых, обеспечению высокого качества поверхности. Для проведения точных проверок следует использовать такое оборудование, как координатно-измерительные машины. Одновременно необходимо создать надежную систему отслеживания производства. Необходимо регистрировать источник материала для каждой партии деталей, изготовленных методом прецизионной штамповки металла. Также следует регистрировать параметры процесса. Это упрощает отслеживание проблем и позволяет своевременно вносить корректировки при их возникновении.Три ключевых пункта контроля качества в производстве прецизионных металлоконструкцийВ документе четко указано, что контроль технологического процесса важнее, чем проверка готовой продукции. Эта концепция в равной степени применима к штамповке стали и алюминия.

V. Практические примеры: Оптимизация применения двух базовых материалов

Предприятие по производству автомобильных запчастей улучшило как качество продукции, так и эффективность производства за счет оптимизации процесса высокоточной штамповки металла при изготовлении кронштейнов двигателя (сталь) и корпусов аккумуляторных батарей (алюминий).

- Применение стали (кронштейн двигателя): Для высокопрочной стали, используемой в кронштейнах двигателя, предприятие скорректировало зазор в пресс-форме до 71 Т3Т толщины материала и выбрало штамповочное оборудование мощностью 1200 кН. Благодаря применению сегментированного процесса штамповки — сначала предварительная формовка, а затем точная штамповка — удалось эффективно избежать проблем с растрескиванием, увеличив процент прохождения штамповки прецизионных металлических деталей с 851 Т3Т до 981 Т3Т.

- Применение алюминия (корпус батареи): При штамповке алюминиевого корпуса батареи предприятие применило азотирование пресс-формы, выбрало водорастворимые смазки и добавило в технологию процесс калибровки упругого восстановления. Для соответствия высоким требованиям к точности штамповки металлических деталей электромобилей, погрешности размеров контролировались в пределах ±0,02 мм.

Этот случай наглядно доказывает, что точная настройка методов прецизионной штамповки металла в соответствии с характеристиками стали и алюминия может значительно повысить конкурентоспособность продукции. Для получения дополнительной информации о примерах из практики отрасли, вы можете обратиться к разделу «Как выбрать завод по производству прецизионных листовых металлов? Ключевые моменты здесь«Для получения полного опыта на всех этапах процесса, от проектирования до массового производства».

VI. Заключение: Методы точного контроля для содействия развитию

Основные методы прецизионной штамповки металла для стали и алюминия заключаются в «адаптации к материалу» — оптимизации конструкции пресс-формы на основе характеристик материала, точной настройке параметров процесса и усилении взаимодействия между участниками процесса и контроля качества. Будь то прецизионная штамповка металла…нг Для производителя или предприятия, работающего в смежных отраслях, освоение этих основных технологий может эффективно повысить качество и эффективность производства прецизионных деталей, изготовленных методом штамповки металла, что позволит им получить преимущество в условиях жесткой рыночной конкуренции.

Если вы столкнулись с техническими трудностями в процессе прецизионной штамповки металла из стали и алюминия, или если вам необходимо изготовить на заказ высококачественные детали методом прецизионной штамповки металла, пожалуйста, немедленно свяжитесь с компанией Vanmodel Sheet Metal. Опираясь на профессиональную техническую команду и богатый практический опыт, мы предоставим вам комплексные услуги по изготовлению деталей методом прецизионной штамповки металла на заказ.