Automotive Industry

When 12,000 EV Recalls Trace Back to a Single Faulty LiDAR Bracket: The Unseen Challenge

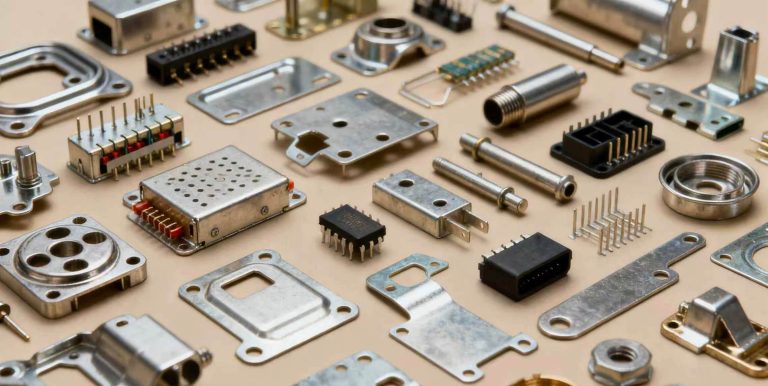

In the electric vehicle industry, a seemingly minor sheet metal bracket defect can trigger a chain reaction of technical failures.

In 2023, a prominent electric vehicle manufacturer was forced to recall 12,000 vehicles due to a single faulty LiDAR bracket. Vibration-induced metal fatigue cracked the mount, misaligning sensors and triggering false collision warnings.

This was not an isolated incident. As the automotive industry transitions from traditional internal combustion engines to electric vehicles, Tier 1 and Tier 2 suppliers face a critical challenge: manufacturing sheet metal components that can withstand harsh road conditions.

As a sheet metal solutions partner to BMW, Tesla, and BYD suppliers, Vanmodel addresses these failures through the following approaches:

The Vibration Killer: 3 Engineering Secrets

Topology-Optimized Designs

In component design, we utilize Altair simulation technology to identify stress concentrations in brackets and mounts.

By predicting vibration response through finite element modeling, our redesigned brake sensor bracket now withstands 20G vibration (increased from 8G).

This methodology allows us to proactively identify potential failure points that would be overlooked in traditional design processes.

Fatigue-Resistant Materials

Material selection is crucial for resisting vibration fatigue. We employ:

- 6061-T6 Aluminum Alloy: Offers 35% higher fatigue strength than standard 6061 aluminum

- Precision Stamping: Achieves ±0.05mm tolerance on AMADA servo presses, preventing micro-cracks

- High-Strength Steel: HRC 45 grade provides superior structural support

The natural frequency and vibration modes of metal structures are functions of their mass and stiffness, making proper material selection essential.

Damping Integration

- Laser-cut elastomer slots: Absorb harmful resonance, reducing vibration transmission to sensors

- Electrically isolated mounts: Prevent EMI interference in ADAS enclosures

By applying appropriate boundary conditions, we can isolate critical areas and select test frequencies to excite the desired characteristic modes.

Speed Advantage for EV Startups

In the competitive EV market, time-to-market directly correlates with market share. We help customers accelerate product development through:

- 15-Day Tool-and-Die: Progressive stamping dies for high-volume production needs

- Prototype-to-Production: The same AMADA RG-100 press handles 5-piece samples and 50,000-unit batches

- Surface Treatment: E-coating, zinc-nickel plating for corrosion protection

Automotive-Grade Capabilities

Our capabilities meet the most stringent automotive standards:

- Tolerance: ±0.1mm for stamped parts

- Materials: HRC 45 high-strength steel, Al 6061-T6, copper-nickel EMI shielding materials

- Compliance: IATF 16949-ready processes

Vanmodel sheet metal sensor mounts passed 1,000-hour salt spray and vibration tests on the first attempt—saving customers $250,000 in validation rework costs.

Conclusion

In the electric vehicle and autonomous driving sectors, every component must be reliable. Vibration fatigue isn’t an afterthought but a challenge that must be addressed from the initial design stage.

By combining topology optimization, carefully selected materials, and innovative damping technologies, we ensure that LiDAR brackets and other critical components maintain their integrity and functionality even under the most demanding road conditions.

Vanmodel Sheet Metal—Precision Sheet Metal Solutions for the Automotive Industry

Trusted Partner to BMW, Tesla, and BYD Suppliers

Stop Vibration Failures Now

Request a Free Vibration Simulation Report for Your Design