From Metal Stamping Manufacturing to Precision Sheet Metal Fabrication

In modern industrial production, metal processing accuracy and efficiency determine product quality and competitiveness. As a professional metal processing enterprise with years of experience, we offer a full-process service system from metal stamping manufacturing to precision metal fabrication. We provide diverse solutions like precision metal stamping and custom precision metal stamping services to help clients gain market advantages.

I. Deepen Metal Stamping Manufacturing, Lay a Solid Quality Foundation

Metal stamping manufacturing is the basis of metal processing, and its technology affects subsequent process quality. We pursue excellence in equipment and technology, with multiple advanced international stamping machines to handle different specifications and materials. These machines process both small precision parts and large structural components.

In production, we strictly control every link: we select high-quality raw materials meeting international standards. Our engineers design optimal stamping plans based on client needs, material properties and product uses. A real-time monitoring system tracks stamping pressure, speed, temperature to ensure qualified stamped metal parts. We have served automotive, electronics, home appliance and medical device industries, winning client recognition.

Meanwhile, we keep investing in technological innovation, exploring cold and hot stamping optimizations. We also upgrade equipment for energy efficiency to achieve green and sustainable development.

II. Focus on Precision Metal Stamping, Build High-Accuracy Processing Capability

Precision metal stamping is a core metal processing technology and our core competitiveness. It requires micron-level error control, demanding strict equipment, technology and personnel.

To ensure accuracy, we introduce high-precision CNC stamping equipment, paired with molds accurate to 0.005mm. Our experienced team adjusts parameters flexibly to meet precision metal stamping part requirements.

We offer customized services for different industries: we provide EV metal parts stamping for the automotive sector. For electronics, we stamp fine structures for small, highly integrated components. For medical devices, we follow quality standards to ensure biocompatibility and safety. Now we are long-term partners of many well-known enterprises.

III. Expand Precision Metal Fabrication, Achieve Full-Process Service Closure

To meet diverse market needs, we introduce precision metal fabrication, forming a full process from stamping to fabrication and offering one-stop solutions.

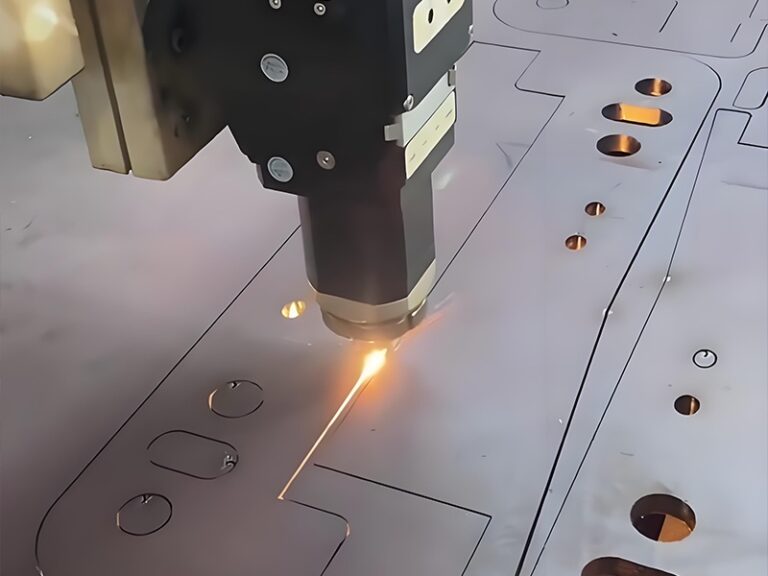

Precision metal fabrication includes laser cutting, bending, welding and surface treatment. Laser cutting enables high-precision sheet cutting with smooth, burr-free edges. CNC bending machines control angles and sizes accurately. Professional welders use advanced techniques to ensure joint strength and tightness. Surface treatment options like galvanizing, chrome plating and spraying enhance corrosion resistance and appearance.

This business coordinates with stamping services. Clients only need to provide drawings; we handle the whole process from stamping to fabrication and deliver finished products. This reduces client communication and time costs, avoiding quality deviations and delays from multi-link outsourcing. For example, we once delivered high-precision metal shell components for a communication client via this full process.

IV. Provide Custom Precision Metal Stamping Services, Meet Personalized Needs

For different industry needs, we offer custom precision metal stamping services and tailor-made solutions.

In the service, we first communicate deeply with clients to understand product uses, performance requirements, working environments and batch needs. Our engineers then conduct process analysis and design, including mold design, material selection and parameter setting. After client confirmation of samples, we start mass production.

This service handles complex needs: it stamps hard-to-process materials like titanium and magnesium alloys. It processes parts with special shapes like irregular holes and multi-step structures. It meets ultra-high precision size and geometric tolerance requirements. We once produced high-demand precision metal gaskets for automotive engine clients. We also serve high-end fields like aerospace and instrumentation.

V. Strict Quality Control and Efficient Delivery, Ensure Cooperation Experience

For all businesses, we prioritize product quality and delivery efficiency. We provide quality services through strict quality control and efficient production management.

In quality control, we build a full-process inspection system from raw material storage to finished product delivery. We test raw material composition and mechanical properties before storage. Each production step has inspection, using coordinate measuring machines and projectors to test part size, accuracy and appearance. We conduct final inspections before delivery to ensure 100% qualification. We also hold ISO9001 certification, integrating quality management into all links.

In delivery, we optimize production planning and scheduling, using advanced systems for real-time monitoring and adjustment. We arrange tasks reasonably to utilize resources and shorten cycles. For urgent orders, we activate emergency plans to ensure delivery dates. For years, our on-time delivery rate has stayed high, winning wide client recognition.

VI. Contact vanmodel Sheet Metal Now, Start Efficient Metal Processing Cooperation

We are committed to providing professional, efficient and high-quality metal processing services. No matter which industry you are in—automotive, electronics, home appliances, medical devices, aerospace—or whether you have standard batch or custom needs, we can offer satisfying solutions with our technical strength and experience.

If you need a reliable metal processing partner and full-process solutions, please contact vanmodel sheet metal now. Our professional team will provide one-on-one consulting and detailed plans to create a better industrial future with you!