A Comprehensive Guide to the Role of Pneumatic Bending Machines in Sheet Metal Processing

Sheet metal processing serves as a core link in metal forming within modern manufacturing. It directly impacts product quality, precision, and production efficiency. As a key piece of equipment in sheet metal machinery, pneumatic bending machines play an irreplaceable role in the field of precision sheet metal fabrication with their unique advantages. This article will delve into how pneumatic bending machines reshape the sheet metal processing workflow and reveal the core secrets behind their ability to enhance the efficiency of metal part forming.

Pneumatic Bending Machines: The Efficiency Engine for Precision Sheet Metal Manufacturing

Precision sheet metal fabrication imposes extremely strict requirements on processing accuracy. From millimeter-level dimension control to the precise rendering of radians, every detail can potentially affect the performance of the final product. Pneumatic bending machines, with their stable power output and precise control capabilities, have become core equipment in precision sheet metal fabrication.

Compared with traditional mechanical bending machines, pneumatic bending machines generate pressure by driving pistons with compressed air. This design enables more uniform force transmission and avoids stress fluctuations that may occur in mechanical transmission. This feature allows them to maintain consistent bending accuracy when processing sheet metal—whether it is aluminum foil as thin as 0.1mm or steel plates as thick as 10mm. In precision sheet metal fabrication, this stability directly translates to an increase in product qualification rates. According to industry data, production lines using pneumatic bending machines can reduce product defect rates by more than 30%.

Furthermore, the response speed of pneumatic bending machines far exceeds that of traditional equipment. In sheet metal processing, the entire process—from positioning the workpiece to be processed to completing the bending action—can be shortened to less than 0.5 seconds. For mass production needs, this means the daily production capacity can be increased by 40%. It is this dual advantage of “high precision + high speed” that makes pneumatic bending machines the first choice for precision sheet metal fabrication enterprises when upgrading their equipment.

Adapting to Diverse Materials and Expanding the Boundaries of Sheet Metal Processing

Sheet metal comes in a variety of materials, ranging from common aluminum sheet metal and 304 sheet metal to high-strength alloy steel plates. Materials with different physical properties impose differentiated requirements on processing equipment. Pneumatic bending machines, however, can perfectly meet the processing needs of various types of sheet metal thanks to their flexible pressure adjustment capabilities.

For relatively soft materials like aluminum sheet metal, pneumatic bending machines can reduce the working pressure. This prevents wrinkles or cracks from forming during the bending process. When dealing with harder materials such as 304 sheet metal, they can instantly increase the pressure to ensure the bending angle is precise. This adaptability not only reduces the time cost of equipment replacement but also enables sheet metal processing enterprises to undertake more personalized and unique orders. They can efficiently complete tasks ranging from customized custom metal brackets to standardized laser-cut steel panels.

In actual production, a company specializing in precision sheet metal fabrication once encountered a problem. A customer required the processing of both 6061 sheet metal and thick-walled stainless steel plates. Traditional equipment needed frequent parameter adjustments, resulting in low production efficiency. After introducing a pneumatic bending machine, operators only needed to select the corresponding type of sheet metal from the preset material parameter library. The equipment would then automatically match the pressure and speed. As a result, the daily processing volume increased from 200 pieces to 350 pieces, perfectly solving the pain point of multi-material processing.

Intelligence in Sheet Metal Machinery: The Efficiency Secret of Pneumatic Bending Machines

With the advancement of Industry 4.0, sheet metal machinery is rapidly upgrading toward intelligence and high efficiency. Pneumatic bending machines have demonstrated strong adaptability in this process and have become the key to improving efficiency.

Modern pneumatic bending machines are generally equipped with numerical control systems. These systems can store hundreds of bending programs through programming. When processing the same type of sheet metal, operators only need to call up the preset program to achieve “one-click bending.” This significantly reduces the time spent on manual adjustments. In precision sheet metal fabrication, this standardized operation not only lowers the reliance on the skills of operators but also ensures the consistency of each product. This stability is particularly important for custom sheet metal enclosures that require mass production.

In addition, the energy consumption advantage of pneumatic bending machines cannot be ignored. Compared with hydraulic bending machines, their energy consumption in the standby state is reduced by more than 60%. They also do not require frequent replacement of hydraulic oil, cutting maintenance costs by nearly 50%. For sheet metal workshops, long-term use can significantly reduce production costs and indirectly enhance the competitiveness of the enterprise.

What is more noteworthy is that some high-end pneumatic bending machines have achieved linkage with sheet metal laser cutting equipment. Through data sharing, sheet metal after laser cutting can directly enter the bending process. This eliminates the need for secondary positioning, shortening the connection time of the entire production process by 30%. This “cutting-bending” integrated model is becoming a mainstream solution for precision sheet metal fabrication companies to improve efficiency.

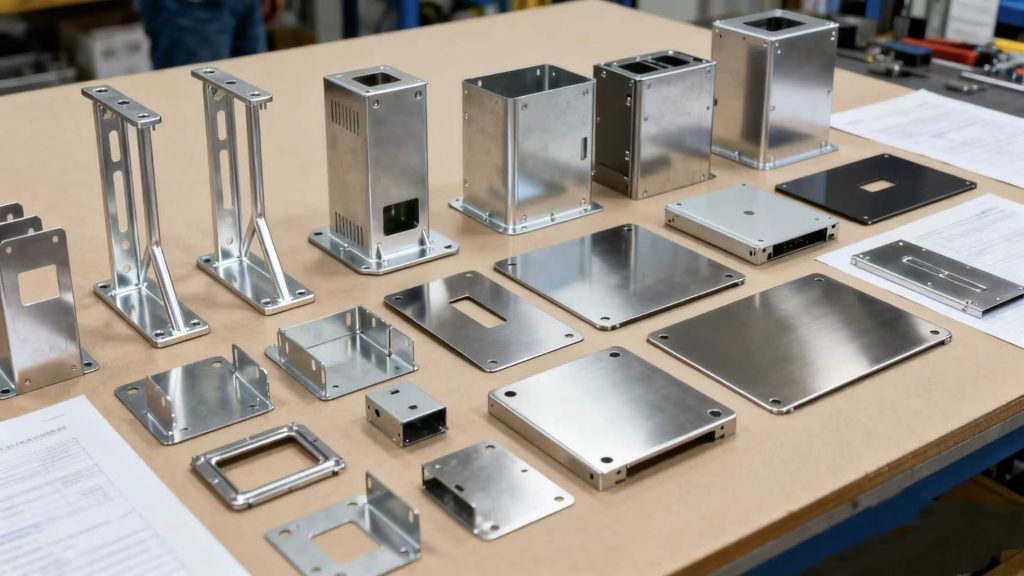

From Customized Needs to Mass Production: Full-Scenario Empowerment of Pneumatic Bending Machines

In the field of sheet metal processing, demands often feature a combination of “multiple varieties, small batches” and “few varieties, large batches.” Pneumatic bending machines, with their flexibility and stability, can seamlessly cover all-scenario processing needs and provide comprehensive support for precision sheet metal fabrication.

For bending needs after custom metal cutting, pneumatic bending machines can quickly adjust parameters. This allows them to meet the personalized requirements of different customers for angles and radians. For example, when producing custom metal enclosures, customers may need to adjust the bending angle according to the internal structure of the equipment. The real-time pressure feedback system of pneumatic bending machines ensures that each adjustment is accurate. This avoids material waste caused by repeated trial and error.

In mass production, the continuous operation capability of pneumatic bending machines becomes even more prominent. An auto parts supplier once used a pneumatic bending machine to process sheet metal brackets for automobile chassis. By combining an automated feeding device with the bending machine, they achieved a stable output of 500 pieces per hour. This efficiency was nearly double that of traditional equipment. This high-efficiency production capacity enables enterprises to be more flexible when responding to peak order periods and meet order demands effectively.

In addition, for scenarios like sheet metal prototyping that have high timeliness requirements, the quick mold change capability of pneumatic bending machines can shorten the prototype delivery cycle to within 24 hours. This helps customers advance their product research and development processes more quickly.

Selecting the Right Sheet Metal Machinery to Maximize the Value of Pneumatic Bending Machines

To fully leverage the role of pneumatic bending machines in precision sheet metal fabrication, selecting suitable equipment is a crucial step. When purchasing, enterprises need to comprehensively evaluate the pressure range, bending length, and intelligence level of the equipment. They should base this evaluation on the type, thickness of the sheet metal they process, and their production capacity requirements.

For enterprises mainly engaged in processing aluminum sheet metal and thin steel plates, small and medium-sized pneumatic bending machines can meet their needs. If thick plates or high-strength alloy materials are involved, high-pressure models should be selected. At the same time, priority should be given to equipment with data traceability functions. This is very important for quality control in precision sheet metal fabrication. By recording the parameters of each bending operation, enterprises can quickly trace the source of problems and continuously optimize the production process.

In addition, regular maintenance is key to ensuring the long-term stable operation of pneumatic bending machines. It is recommended that sheet metal workshops establish an equipment maintenance plan. They should focus on inspecting core components such as the cleanliness of the air source and the tightness of the piston. This prevents production delays caused by equipment failures.

Conclusion

As an innovative force in sheet metal machinery, pneumatic bending machines are reshaping the industry standards of precision sheet metal fabrication. They achieve this through their characteristics of high precision, high efficiency, and high adaptability. Whether it is improving the qualification rate of sheet metal processing or expanding the production boundaries of multi-material and multi-scenario processing, they bring tangible efficiency improvements to enterprises.

If your enterprise is seeking a breakthrough in the efficiency of precision sheet metal fabrication or needs solutions for adapting to multi-material sheet metal processing, please feel free to contact Vanmodel Sheet Metal. We have a professional technical team and advanced pneumatic bending equipment. We can customize processing solutions according to your needs and help your production efficiency reach a new level. Contact us now to embark on a new era of efficient sheet metal processing!

With the role of pneumatic bending machines in precision sheet metal fabrication clarified, shifting focus to Three Key Quality Control Points in Precise Metal Production will help refine your metal processing quality management.

https://vanmodel-sheetmetal.com/wp-admin/post.php?post=2947&action=edit