Collaboration between Precision Metal Machining and Stamping

With the rapid development of the consumer electronics industry, the update and iteration speed of 3C products is constantly accelerating. Users have higher requirements for product precision, performance and delivery efficiency. As the core components of 3C products, the production cycle of precision parts affects the launch rhythm of the entire product. To break the problems of slow delivery and low efficiency under the traditional production mode, the industry is actively exploring technical collaboration paths. Among them, the in-depth collaboration between precision metal stamping and precision metal machining has become a key force driving the acceleration of delivery of precision parts for consumer electronics. It has effectively shortened the production cycle of 3C products and provided strong support for enterprises to seize market opportunities.

Precision Metal Stamping: The Efficiency Cornerstone of Mass Production of Precision Parts for Consumer Electronics

As core components of 3C products, precision parts’ production cycle affects the entire product launch rhythm. To solve slow delivery and low efficiency in traditional production, the industry is exploring technical collaboration paths. In-depth collaboration between precision metal stamping and machining has become key to accelerating consumer electronics precision parts delivery. This greatly reduces processing steps and improves production efficiency.

Precision control in precision metal stamping directly dictates part quality. Top manufacturers use high-precision equipment and advanced mold technology to limit batch dimensional errors to the micron level, fully satisfying consumer electronics’ strict precision requirements. For mobile phone camera module brackets, stamping precisely controls thickness, aperture, and flatness, ensuring stable module installation and enhanced shooting performance. Additionally, mature stamping lines deliver 10,000 to 100,000 precision parts daily, guaranteeing sufficient supply for large-scale consumer electronics production and preventing downtime from part shortages.

In addition, precision metal stamping can flexibly cooperate with other processes to support subsequent precision metal machining. After stamping completes initial part forming, parts are sent to precision metal machining for fine processing. This not only reduces the workload of precision metal machining but also further improves the overall precision of parts. It realizes the complementary advantages of the two processes.

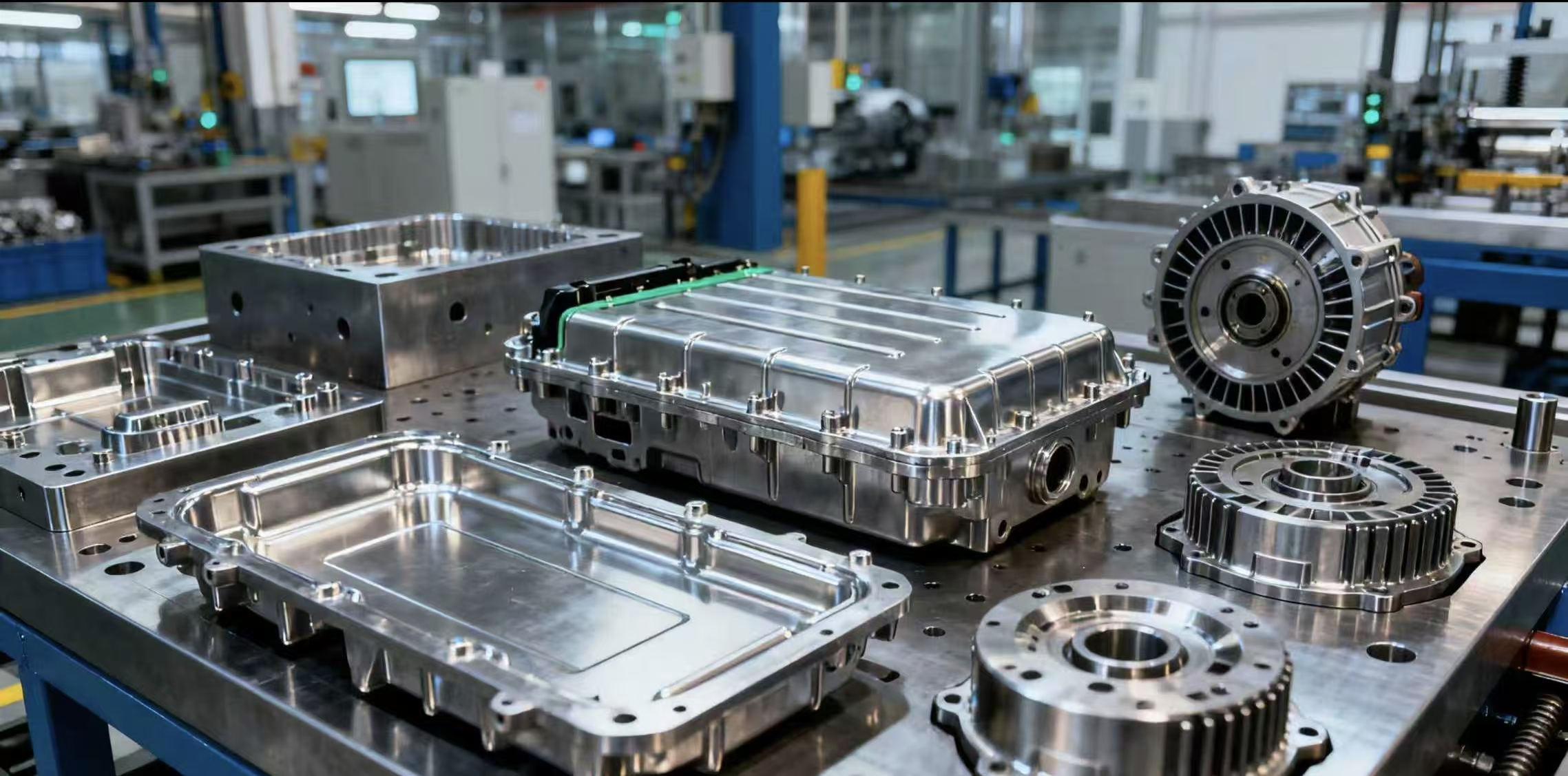

Precision Metal Machining: The Core Guarantee of High-Precision Processing of Precision Parts for Consumer Electronics

If precision metal stamping is the efficiency cornerstone for mass-producing consumer electronics precision parts, precision metal machining is the core guarantee for high-precision part processing. Precision metal machining uses numerical control processing equipment, such as CNC lathes, CNC milling machines, machining centers, etc. It controls the processing process through computer programs. It can perform a series of high-precision cutting, drilling, milling and other processing operations on metal materials. This meets the requirements of consumer electronics precision parts for complex structures and ultra-high precision.

Indispensable Role in Key 3C Parts Processing

In 3C products, many key precision parts such as chip heat dissipation bases and connector pins not only require complex geometric shapes but also have extremely high standards for surface roughness and dimensional precision. These are inseparable from the precise processing of precision metal machining. For example, the chip heat dissipation base needs to be closely attached to the chip to achieve efficient heat dissipation. Its surface flatness requirements are extremely high. Our precision metal machining’s milling and grinding processes control the base’s surface roughness below Ra0.8 to ensure the heat dissipation effect.

Strong Flexible Production Capabilities

Precision metal machining also has good flexible production capabilities. It can quickly respond to the design change needs of consumer electronics parts. When enterprises need to adjust the part structure, they only need to modify the numerical control program. There is no need to replace a large number of equipment and molds. This greatly shortens the product R&D cycle and provides solid technical support for the rapid iteration of 3C products.

Continuous Improvement of Processing Efficiency

The processing efficiency of precision metal machining is also constantly improving. The application of high-speed machining technology and multi-axis linkage machining technology further improves the processing speed and precision of precision metal machining equipment. It can complete the processing tasks of complex parts in a shorter time. For example, an enterprise introduced a five-axis linkage machining center for precision metal machining of mobile phone middle frames. Compared with traditional three-axis machining equipment, the processing time is shortened by 30%, and the precision and surface quality of parts are also significantly improved.

Synergy with Precision Metal Stamping to Shorten Production Cycles

When cooperating with precision metal stamping, precision metal machining can quickly perform subsequent fine processing on stamped and formed parts. This further shortens the overall production cycle of parts.

Case Study: Efficiency Upgrade in Smartphone Metal Middle Frame Production

For example, in the production process of smartphone metal middle frames, the traditional production mode may need to rely solely on precision metal machining for overall processing. This not only takes a long time but also wastes a lot of materials. Adopting the stamping-machining collaborative mode, metal plates are first stamped into preliminary middle frame shapes to remove most excess material. Then, precision metal machining finely processes key parts like edges and interfaces. This method reduces machining allowance, shortens time, cuts material loss, and boosts production efficiency. Statistics show this mode shortens smartphone middle frame production cycles by over 25%, improving enterprise delivery capacity.

Collaborative Advantages in Production Plan Management

In addition, the collaboration between precision metal stamping and precision metal machining is also reflected in the overall arrangement of production plans. Through the digital management system, enterprises can real-time monitor the production progress of precision metal stamping production lines and precision metal machining equipment. It realizes the orderly flow of parts and avoids production delays caused by poor process connection. At the same time, the unification of technical standards in the two processes also reduces the quality inspection time of parts between different processes and further speeds up the production rhythm of parts.

Supported by Industry-Leading Technologies: Helping the Collaborative Upgrade of Precision Metal Stamping and Precision Metal Machining

To further improve the collaborative effect between precision metal stamping and precision metal machining, the industry continues to introduce advanced technologies to accelerate the upgrading and optimization of the two processes.

Technological Upgrades in Precision Metal Stamping

In terms of precision metal stamping, enterprises have adopted intelligent mold monitoring systems. They can real-time monitor the wear of molds and parameters such as pressure and temperature during the stamping process. They timely detect mold failures and perform maintenance to avoid production interruptions caused by mold problems. This ensures the stable operation of the precision metal stamping production line. At the same time, the application of 3D printing technology in mold manufacturing has also shortened the R&D and manufacturing cycle of precision metal stamping molds. It enables enterprises to respond faster to the new product development needs of consumer electronics parts.

Technological Innovations in Precision Metal Machining

In the field of precision metal machining, the integration of artificial intelligence technology makes the processing process more intelligent and efficient. The intelligent numerical control system can automatically optimize processing parameters according to the material, shape and processing requirements of parts. It improves processing efficiency and precision. In addition, the combination of industrial robots and precision metal machining equipment has also realized the automatic loading, unloading and handling of parts. This reduces manual operation time and further improves production efficiency. For example, after an enterprise introduced industrial robots into the precision metal machining workshop, the loading and unloading time of parts was shortened by 40%, and the utilization rate of equipment was also significantly improved. When cooperating with precision metal stamping in production, precision metal machining can quickly perform subsequent fine processing on stamped and formed parts, further shortening the overall production cycle of parts.

Digital Collaboration Platform: Strong Support for In-Depth Collaboration

In addition to the technological upgrades of precision metal stamping and precision metal machining themselves, the construction of a digital collaboration platform also provides strong support for the in-depth collaboration of the two processes. Through this platform, the design department, precision metal stamping workshop and precision metal machining workshop can realize real-time data sharing. Changes in design drawings can be quickly transmitted to the production link. This avoids production errors caused by information lag. At the same time, the platform can also analyze production data, optimize production plans, improve the collaboration efficiency between precision metal stamping and precision metal machining, and further shorten the production cycle of 3C products.

Choose a Professional Partner: Vanmodel Sheet Metal to Escort the Delivery of Your Precision Parts for Consumer Electronics

In consumer electronics precision parts production, the collaboration effect of stamping and machining depends on both technical level and partner professionalism. As an industry-leading precision metal enterprise, Vanmodel Sheet Metal boasts rich experience and advanced technology in both processes. It can provide consumer electronics enterprises with comprehensive precision part solutions.

Advanced Equipment and Professional Mold Design Capabilities

Vanmodel Sheet Metal has multiple advanced precision metal stamping production lines. It is equipped with high-precision stamping equipment and a professional mold design team. It can customize various precision stamping molds according to customer needs to achieve efficient mass production of parts. The company also has multiple high-end precision metal machining equipment, including five-axis machining centers and high-speed CNC lathes. It has the high-precision processing capability of complex precision parts to ensure that the part quality fully meets customer requirements.

Seamless Process Collaboration and Digital Production Management

In terms of process collaboration, Vanmodel Sheet Metal has established a sound digital production management system. It can realize the seamless connection between precision metal stamping and precision metal machining. It reasonably arranges production plans to minimize the part production cycle. In addition, the company also provides custom metal stamping for high-precision applications and custom precision metal stamping services. It can meet the production needs of consumer electronics enterprises for personalized precision parts.

Professional Support and Cooperation Invitation

Worry about the delivery efficiency and quality of consumer electronics precision parts? Want to shorten 3C product production cycles via the collaboration of precision metal stamping and machining? Contact Vanmodel Sheet Metal immediately. We will provide you with professional technical support and efficient production services according to your specific needs. We help your enterprise seize opportunities in the fierce market competition and achieve rapid development.

How to choose a precision metal enterprise?

https://vanmodel-sheetmetal.com/wp-admin/post.php?post=2984&action=edit