Highlights of the Sheet Metal Zone at China International Industry Fair

In the golden autumn season, the China International Industry Fair (CIIF) kicks off as scheduled. As a benchmark exhibition in the industrial sector, its Sheet Metal Zone has always been a core focus attracting industry attention. With the theme “Precision Intelligent Manufacturing, Customizing the Future”, this year’s zone gathers world-class sheet metal technologies, equipment and solutions. The innovative achievements of precision sheet metal fabrication and efficient custom cut metal solutions are particularly eye-catching, presenting attendees with an industry feast that combines technical depth and application value.

Highlight 1: Technological Iteration, Dual Breakthroughs in Precision and Efficiency

In the field of sheet metal processing, the precision of precision sheet metal fabrication directly determines the quality of end products. The Sheet Metal Zone at this CIIF provides the latest industry answers to this. Many exhibitors displayed precision sheet metal fabrication technology. This technology controls processing tolerances within 0.01 millimeters. Thus, it completely breaks the precision bottleneck of traditional processes. This breakthrough is undoubtedly a major boon for fields with strict precision requirements such as aerospace and medical equipment.

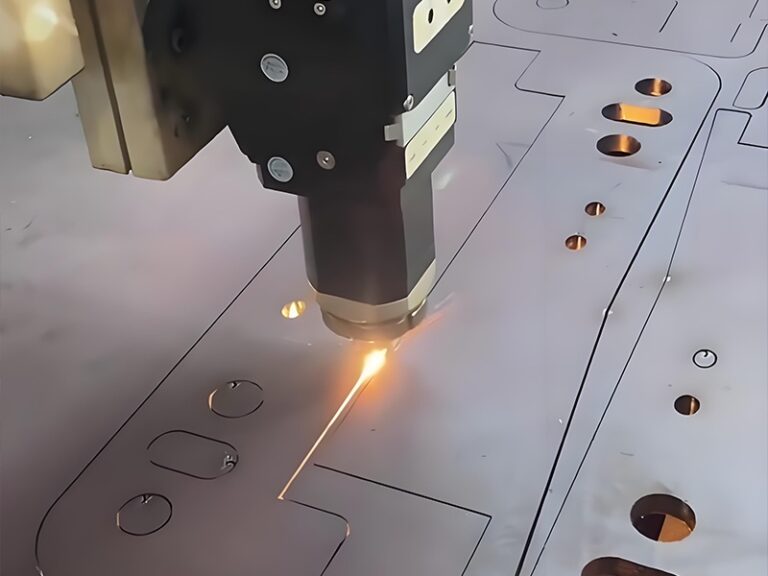

The core of this breakthrough lies in technological integration—the in-depth linkage of laser cutting and CNC processing. It not only improves the precision of precision sheet metal fabrication but also increases efficiency by more than 30%. An intelligent processing equipment on site attracted widespread attention. It can automatically complete multiple processes such as custom cut metal, bending and welding. For different sheet metal materials like 304 sheet metal and 6061 sheet metal, it can accurately match processing parameters, perfectly interpreting the development direction of precision sheet metal fabrication of “improving quality through intelligence and efficiency through technology”.

Participating precision sheet metal fabrication companies also brought customized solutions to meet the market demand for small batches and multiple specifications. Custom metal brackets require precision processing. Custom sheet metal enclosures need integrated manufacturing. We can quickly deliver both through precision sheet metal fabrication technology. This is highly consistent with the “flexible production” concept emphasized in the article “How to Balance Functionality and Design in Custom Sheet Metal Fabrication?“, providing a reference practical path for the industry.

Highlight 2: Upgraded Custom Cut Metal Solutions, Adapting to Full-Scenario Processing Needs

If precision sheet metal fabrication is the “core brain” of sheet metal processing, custom cut metal is the “key hands and feet” to achieve precision manufacturing. The custom cut metal technology is in the Sheet Metal Zone of this CIIF. It has upgraded from single-size cutting. Now it provides full-scenario customized services. Whether it is the thin cutting of aluminum sheet metal or the heavy processing of stainless steel sheet metal, suitable solutions can be found.

A custom cut metal system displayed by an exhibitor allows customers to upload processing drawings through an online platform. The system automatically parses and generates cutting plans, with only 24 hours from order placement to finished product delivery. This efficient service model exactly solves the industry pain points mentioned in the article “Looking for Small-Batch Custom Metal Sheet Fabrication“, making small-batch and personalized custom cut metal needs no longer restricted by production cycles.

In terms of material adaptability, custom cut metal technology has also achieved full coverage. For the high-strength characteristics of 6061 sheet metal, a low-speed and high-power cutting method is adopted to ensure smooth cuts. For the corrosion resistance requirements of 304 sheet metal, cutting parameters are optimized to reduce the heat-affected zone. These detailed treatments enable custom cut metal to not only meet size requirements but also maintain material performance. On-site staff introduced that we have widely applied this technology in metal workshops, automobile manufacturing, electronic equipment and other fields — it has become an important support for enhancing product competitiveness.

Highlight 3: Industrial Chain Collaboration, Building a New Ecology of Sheet Metal Intelligent Manufacturing

In addition to breakthroughs in core technologies, the Sheet Metal Zone of this CIIF also shows distinct characteristics of industrial chain collaborative development. Aluminum sheet metal suppliers provide high-quality raw materials. Sheet metal machinery enterprises display intelligent equipment. Precision sheet metal fabricators offer integrated services. From raw materials to finished products, a complete industrial chain closed loop has thus been formed.

In this industrial chain, precision sheet metal fabrication serves as a core link, connecting upstream and downstream resources to achieve information sharing and efficient collaboration. For example, precision sheet metal fabrication enterprises have processing needs. Aluminum sheet metal suppliers can pre-optimize the material ratio of sheet metal based on these needs. Precision sheet metal fabrication manufacturers carry out joint development. Sheet metal laser cutting equipment enterprises participate in this joint development. This makes the equipment more suitable for processing processes. This collaborative model has significantly reduced the production costs of the industry.

At the same time, supporting services in the zone have also attracted much attention. The selection criteria such as “qualification certification” and “technical strength” mentioned in the article “How to Choose a Precision Sheet Metal Factory? Key Points Are Here” have become high-frequency words in on-site industrial chain docking activities. Many metal sheet fabrication enterprises found suitable partners through the exhibition platform, further improving their supply chain systems. The display of supporting products such as custom metal plate and laser cut steel panels also fully reflects the integrity of the industrial chain.

Highlight 4: Green Intelligent Manufacturing as a Trend, Leading the Sustainable Development of the Industry

Guided by the “dual carbon” goals, green intelligent manufacturing has become a consensus in the sheet metal industry. This trend is fully demonstrated in the Sheet Metal Zone of this CIIF. The precision sheet metal fabrication technology displayed by many enterprises has reduced material waste by 30% through optimizing processing processes. Custom cut metal uses laser cutting technology. Compared with traditional cutting methods, this technology reduces energy consumption by 40%. Thus, it achieves a win-win situation of environmental protection and efficiency.

Industry pain points include metal sheet door rust and rust metal sheet wall. Participating enterprises responded to these pain points. They brought new anti-rust processing technologies. These technologies are integrated into the precision sheet metal fabrication process. This extends the service life of sheet metal products and reduces resource consumption. This green concept is consistent with the technical direction mentioned in the article “Must-Know Details for 6061 Aluminum Alloy Sheet Metal Fabrication“, providing a new path for the sustainable development of the industry.

In addition, innovations in sheet metal prototyping technology also provide support for green intelligent manufacturing. Custom metal enclosures samples quickly formed through 3D printing can complete performance testing before mass production, avoiding material waste in traditional trial production. This “test before production” model has become a new choice for precision sheet metal fabrication enterprises.

Seize Industry Opportunities, vanmodel sheet metal Walks with You

This is the Sheet Metal Zone at this CIIF. Its highlights include the concentrated display of precision sheet metal fabrication technology. It also features the focused presentation of custom cut metal technology. Moreover, these highlights indicate the future development direction of the sheet metal industry. Whether it is breakthroughs in precision, improvements in efficiency, or the advancement of green intelligent manufacturing, all bring new development opportunities for enterprises.

As an enterprise deeply engaged in the sheet metal field for many years, vanmodel sheet metal has always followed industry trends. It has mature technologies and rich experience in precision sheet metal fabrication and custom cut metal, and can meet the customized needs of different industries. Do you want to learn more about the technical details of precision sheet metal fabrication? Or do you want to know more about custom cut metal technical details? Maybe you have specific processing needs? Either way, welcome to contact vanmodel sheet metal immediately. We will provide you with professional and efficient solutions, and work with you to embrace the new future of sheet metal intelligent manufacturing.