Global Trends in Precision Metal Processing & Stamping Integration: Hannover Messe Insights

Hannover Messe Germany is an annual “barometer” for global industrial tech. Moreover, it gathers cutting-edge technologies and innovative ideas from around the world. At the 2024 show, deep integration of precision metal stamping and precision metal machining stole the spotlight. In fact, it emerged as a core topic in manufacturing.

Innovations in precision metal stamping were everywhere, spanning automotive and electronic components booths. This technology has not only reshaped traditional metal manufacturing but also maps a clear future for the global precision metal industry. Notably, global metal stamping manufacturers and niche precision firms shared one key message: efficient collaboration between processing and stamping is essential to succeeding in global competition.

Core Trend: Precision Metal Stamping as the Core Engine for Integrated Development

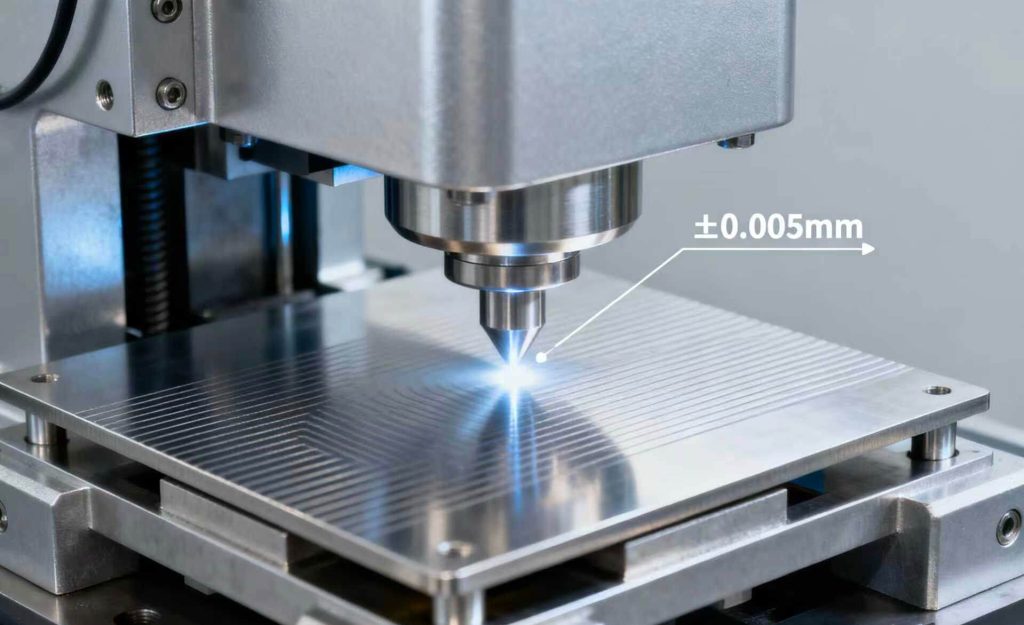

The core exhibition area showcased stunning innovations in precision metal stamping. For example, a German metal stamping manufacturer displayed a fully automated precision stamping line. It merged precision metal stamping with intelligent inspection, controlling dimensional error within 0.005 millimeters. Additionally, it achieved fully unmanned operation from raw materials to finished goods.

On-site technicians explained the value: precision metal stamping parts from this line gain more recognition, as they are ideal for aerospace and medical equipment.

Domestic enterprises also brought innovative solutions to the show. Specifically, one company displayed custom precision metal stamping services that combined precision stamping with CNC machining. This approach solved mass production challenges for complex precision metal stamping parts, which drew significant attention from overseas buyers. Consequently, it proved integrated technology with precision metal stamping at its core is an industry consensus.

As noted in Custom metal stamping for high-precision: Tackling the challenges in EV metal part stamping, high-precision scenarios demand stability and consistency. Importantly, precision metal stamping is the key to meeting these demands.

Technological Breakthrough: Collaborative Innovation of Precision Metal Machining and Stamping

Precision metal stamping is the “backbone” of precision manufacturing, while precision metal machining is the “flesh and blood” that brings it to life. Their collaboration was a key focus at Hannover Messe, with many firms displaying “stamping-machining integration” lines. These lines ended the traditional “stamp first, machine later” model; as a result, they shortened production cycles by over 30% and boosted product qualification rates from 95% to 99.8%.

2.1 EV Metal Parts Stamping: Synergy for Precision and Lightweight

EV metal parts stamping demands higher precision and strength than traditional cars. To address this, one company displayed a battery case solution that merged precision metal stamping with precision metal machining. It added precision milling right after stamping, which avoided errors from secondary clamping.

Stamped metal parts from this process are 15% lighter; furthermore, they improve battery heat dissipation. Precision Metal Stamping and Machining Synergy: Unlocking New Possibilities predicted this trend, and Hannover Messe practices ultimately confirmed it.

Micro-Precision Components: Merging Stamping with Finishing Machining

Consumer electronics are getting thinner, lighter, and smaller. As a result, this raises demands for precision metal stamping parts—especially in dimensional accuracy and surface finish. A micro-connector line was on display that used high-speed milling to trim precision-stamped parts. The connector pins measure just 0.1 millimeters, yet they still ensure stable conductivity. This integration effectively expands the application of precision metal stamping.

Process Integration: Breaking the “Stamping-First, Machining-Later” Barrier

Technological breakthroughs hinge on breaking process silos. Fortunately, integrated lines enable seamless stamping and machining by using intelligent control systems to optimize parameters. This eliminates cumulative errors from multiple clamping. For complex precision metal stamping parts, this mode not only boosts efficiency but also ensures consistent quality. In fact, it is widely recognized in aerospace and medical fields.

Market Demand: Customized Services Driving the Upgrade of Metal Stamping Manufacturing

“Customization” was a top term among global buyers at Hannover Messe. Consequently, it is driving metal stamping manufacturing toward personalization and precision. Customers no longer want standardized metal parts stamping products; instead, they want solutions tailored to their production processes. Thus, custom metal stamping for high-precision applications is now a market hotspot.

An overseas medical device firm representative shared their specific needs: they need precision metal stamping parts that meet biocompatibility standards, and the parts must also fit different medical instruments. Additionally, they require full-process custom services—from design to mass production.

A domestic enterprise displayed custom precision metal stamping services to meet this need. It built a digital design platform and collaborated with customers on product development. Moreover, it used simulation to optimize stamping processes, which shortened development cycles. This transformation turned metal stamping manufacturing from simple processing into a strategic partnership.

Custom metal stamping for high-precision: Tackling the challenges in EV metal part stamping noted customized services are a key driver. In line with this, Hannover Messe feedback confirmed this trend. Custom precision metal stamping services create value in aerospace and medical fields; simultaneously, they push firms to upgrade technical and service capabilities. As a result, firms are shifting from processors to solution providers.

Industrial Upgrade: Full-Chain Integration of Precision Metal Fabrication and Stamping

Hannover Messe highlighted full-chain integration of precision metal fabrication and stamping. Importantly, collaboration across raw materials, design, production, inspection, and after-sales is key—it helps metal stamping manufacturers boost core competitiveness.

Raw Material Link: Data-Driven Procurement and Pre-Processing

Full-chain integration starts with raw materials. Specifically, digital systems detect metal sheet properties—mechanical, chemical, and surface quality. This data then feeds into stamping parameter databases to ensure raw materials match stamping needs. For custom metal stamping for high-precision applications, some firms also offer pre-processing services like precision cutting and surface treatment, which lay a solid foundation for subsequent processes.

Production-Inspection Integration: Real-Time Quality Control in Precision Stamping

Integration shines particularly in production and inspection. Intelligent lines are equipped with high-precision visual systems and force sensors that monitor dimensions, defects, and stamping force in real time. If anomalies are found, the system automatically adjusts parameters or stops production. This ensures every precision metal stamping part meets standards. Furthermore, inspection data is synced to a digital platform for traceability and optimization.

After-Sales Service Extension: From Product Supply to Full-Life Cycle Support

Full-chain integration extends beyond production to after-sales. Many metal stamping manufacturers now offer full-life cycle services for precision metal stamping parts, including installation guidance, quality feedback, and maintenance. For high-value stamped metal parts, IoT even enables remote monitoring and diagnosis. This not only reduces customer risks but also improves product utilization, making it a key part of industrial upgrading.

Digital Collaboration Platform: Connecting the Entire Industrial Chain

Digital platforms are the core of full-chain integration. For example, an international giant’s solution integrated precision metal stamping, sheet metal fabrication, and processing through a unified digital platform. This platform connects suppliers, manufacturers, and customers, enabling transparent management from order to delivery. As a result, this model speeds up market response while cutting communication costs and waste. Indeed, it serves as a model for industrial upgrading.

Conclusion: Seize the Integration Trend and Occupy the Foothold in the Global Market

Hannover Messe showcased more than just tech innovations; it also revealed the future of the precision metal industry. The mainstream trend will center on precision metal stamping, as it merges with machining and fabrication. Additionally, it will offer customized, full-chain solutions.

Metal stamping manufacturers and downstream firms must embrace innovation; moreover, they need to strengthen industrial chain collaboration. If you need precision metal stamping parts or custom precision metal stamping services, contact vanmodel sheet metal today. Our leading technology and customized solutions will help you seize valuable global market opportunities.