Capacity Planning Tips for Precision Metal Stamping Part Manufacturers

In the precision metal manufacturing sector, the production capacity of precision metal stamping directly determines an enterprise’s market competitiveness and customer satisfaction. For manufacturers focusing on precision metal stamping production, scientific capacity planning not only prevents order delays and inventory backlogs but also helps seize opportunities in high-growth sectors like new energy vehicles and high-end electronics. This article breaks down core capacity planning tips for precision metal stamping manufacturers from dimensions such as demand forecasting, equipment management, and process optimization, to support efficient production and steady business development.

I. Accurate Demand Forecasting: The Prerequisite for Precision Metal Stamping Parts Capacity Planning

The core starting point of capacity planning is accurate demand forecasting. Capacity layout divorced from market demand will inevitably lead to resource waste. In the precision metal stamping industry, demand fluctuations are closely tied to downstream sector development. For example, growing demand for ev metal parts stamping has directly driven a surge in orders for related precision metal stamping parts. Manufacturers need to establish a multi-dimensional demand forecasting system:

- Deep Customer Collaboration: Clarify delivery cycles, batch changes, and quality requirements for precision metal stamping parts. For customized needs, reserve flexible capacity in advance.

- Macro Industry Analysis: Leverage industry data to monitor trends in key sectors like new energy and 5G communications, and predict peak market demand for precision metal stamping.

- Data-Driven Modeling: Use digital tools to integrate historical order data, and apply algorithm models to forecast demand fluctuations for precision metal stamping parts over the next 3–6 months. Reference can be made to the market analysis logic in How to Choose a Precision Sheet Metal Factory? Key Points Are Hereto reverse-infer capacity needs from the essence of customer demand, ensuring forecasts align with reality. Additionally, establish a dynamic demand adjustment mechanism. When facing sudden market demands (e.g., emergency order increases for ev metal parts stamping from new energy vehicle manufacturers), quickly respond and adjust capacity allocation to avoid idle or overloaded precision metal stamping capacity caused by misjudgment. The triple forecasting approach—”customer demand + industry trends + data models”—lays a solid foundation for precision metal stamping parts capacity planning.

II. Maximizing Equipment Efficiency: The Core Support for Precision Metal Stamping Capacity Improvement

Equipment is the core asset of precision metal stamping production, and its operational efficiency directly determines the capacity ceiling of precision metal stamping parts. Many manufacturers face the contradiction of coexisting equipment idleness and capacity shortages, rooted in the lack of systematic equipment management. To maximize equipment efficiency:

- Classified Equipment Management: Based on process requirements for precision metal stamping parts, divide equipment into general-purpose and special-purpose categories. For example, deploy high-precision stamping equipment for manufacturing high-precision stamped metal parts to match equipment performance with product needs.

- Full-Lifecycle Equipment Maintenance: Conduct regular maintenance and inspections of precision metal stamping equipment. This helps identify potential faults early and avoid production interruptions from downtime. Additionally, introduce an equipment management system. It monitors real-time operational parameters (e.g., stamping speed, qualification rate). Use data-driven management to boost utilization. If needed, upgrade or replace outdated equipment. This prevents production delays from failing custom precision metal stamping services’ precision requirements.

- Optimized Production Scheduling: Use production scheduling systems to scientifically allocate precision metal stamping parts production tasks across equipment, reducing mold changeover time. For example, centralize production of similar metal parts stamping orders to avoid efficiency losses from frequent mold changes. Learn from equipment optimization experiences in How to Double Production Efficiency in Custom Metal Stamping? to further improve precision metal stamping efficiency through equipment linkage and automation upgrades.

III. Process Optimization and Collaboration: The Key Path to Unlocking Precision Metal Stamping Parts Capacity

Efficient production processes are crucial for releasing precision metal stamping capacity. For many manufacturers, capacity bottlenecks stem not from insufficient equipment but from inefficiency caused by redundant processes. Process optimization should cover the entire lifecycle from order receipt to finished product delivery:

- Order Receipt Stage: Establish a rapid quotation and review mechanism to clarify process feasibility and production cycles for precision metal stamping parts, avoiding delays in subsequent capacity planning due to order review holdups.

- Process Design Stage: Optimize mold design and stamping processes based on precision metal stamping technical requirements to reduce rework rates. For custom precision metal stamping services specifically, use simulation technology to pre-optimize process parameters. This ensures successful first-time mold trials and shortens production preparation time. Furthermore, strengthen collaboration between precision metal stamping and precision metal machining. For parts requiring secondary processing, rationalize process handover—this avoids capacity waste from disconnected workflows. Refer to practical methods in Precision Metal Stamping and Machining Collaboration: Unlocking New Possibilities for collaboration tips.

- Production Execution Stage: Implement lean production to eliminate waste such as waiting, transportation, and overprocessing. Establish standardized operating procedures (SOPs) to regulate precision metal stamping operations, ensuring efficient task completion by all employees. Additionally, strengthen workshop on-site management to achieve orderly placement and quick access to materials and tools, reducing non-value-added time. Furthermore, establish a quality traceability system to identify and resolve quality issues in precision metal stamping parts in real time, avoiding capacity occupation from batch rework.

IV. Supply Chain and Team Building: The Guarantee System for Stable Precision Metal Stamping Capacity

Stable capacity output relies on strong supply chain support and professional team guarantees.

Supply Chain Management

Precision metal stamping manufacturers should establish long-term stable partnerships with raw material and mold suppliers to ensure timely supply of steel plates, aluminum materials, and other raw materials, avoiding production interruptions due to shortages. Implement hierarchical supplier management; for core suppliers, sign long-term supply agreements and establish joint inventory mechanisms to ensure raw material supply during surges in precision metal stamping parts demand.

Team Building

Cultivate a professional technical and management team for precision metal stamping. First and foremost, conduct regular skill training to improve frontline operators’ stamping technology and equipment operation capabilities, enabling them to proficiently handle production needs for different types of precision metal stamping parts. Next, strengthen capacity planning training for production managers to enhance their coordination capabilities for production schedules, equipment status, and personnel allocation. Finally, establish a reasonable performance appraisal mechanism, linking precision metal stamping capacity and quality indicators to employee compensation to stimulate production enthusiasm.

For precision metal stamping manufacturers, it is also crucial to monitor industry policies and technological innovations (e.g., environmental policy requirements, application of automation technology in metal stamping manufacturing) and adjust capacity in advance to align with industry development. For example, introducing automated stamping production lines not only improves precision metal stamping capacity but also reduces labor costs and quality fluctuations, enhancing market competitiveness.

V. Digital Empowerment: The Future Direction of Precision Metal Stamping Parts Capacity Planning

In the digital era, intelligent capacity planning with digital tools is essential for precision metal stamping manufacturers.

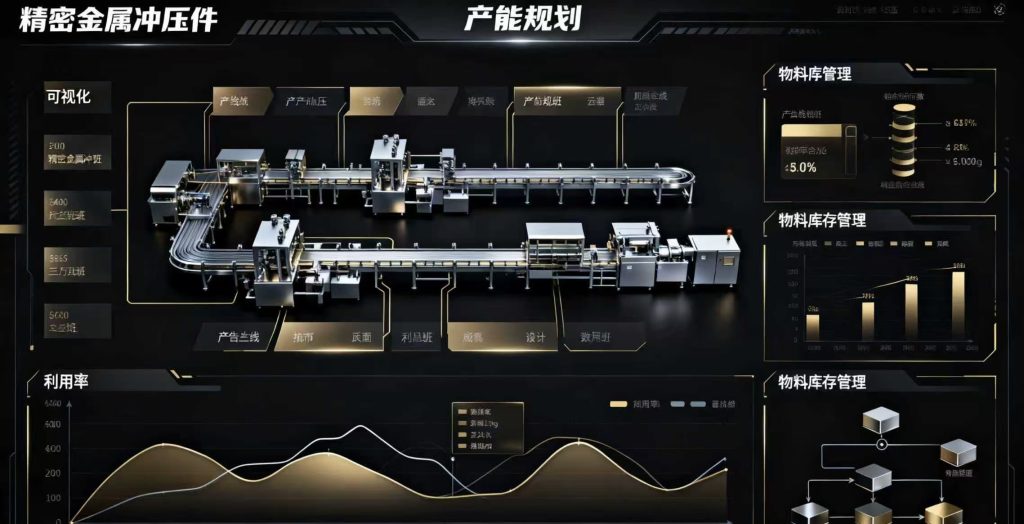

Introduce an ERP system. Integrate order, production, inventory, and supply chain data. Achieve full-process visualization of precision metal stamping parts capacity planning. For example, the system can display real-time equipment capacity load and order progress. Help managers adjust production plans quickly to avoid idle or overloaded capacity.

Use big data analytics to mine precision metal stamping production data. Identify core causes of capacity bottlenecks. For example, analyze equipment data to find excessive mold changeover time. Optimize the process to improve efficiency. Digital tools enable dynamic capacity forecasting. Automatically adjust future precision metal stamping parts production plans based on real-time demand. Enhance scientificity and flexibility.

For manufacturers of custom metal stamping for high-precision applications, digital tools connect customer demand and capacity planning. Receive orders through online platforms. Automatically generate production plans to shorten response time and improve satisfaction. Digital empowerment boosts current precision metal stamping capacity. It also lays the foundation for future expansion and transformation.

Digital Empowerment: Key to Sustainable Capacity Development

Capacity planning is core to precision metal stamping manufacturers’ sustainable development. Scientific operation of each link drives efficient precision metal stamping parts capacity release. This includes demand forecasting, equipment management, process optimization, and digital empowerment. A sound capacity planning system supports enterprises through market fluctuations and industry opportunities. If you face precision metal stamping capacity planning challenges or need custom precision metal stamping parts, contact vanmodel sheet metal immediately. Digital empowerment—can drive efficient release of precision metal stamping parts capacity. We will provide professional solutions for you. Whether responding to current market demand fluctuations or seizing future industry opportunities, a sound capacity planning system provides strong support for enterprises. If you encounter challenges in precision metal stamping capacity planning or have custom needs for precision metal stamping parts, welcome to contact vanmodel sheet metal immediately. We will provide professional solutions for you.