Why Choose Vanmodel sheet metal?

Welcome to Vanmodel Sheet Metal: Your Global Partner in Precision Manufacturing

Where 15 Years of Expertise Meets Uncompromising Quality in Every Component

In an era where precision engineering separates industry leaders from followers, Vanmodel Sheet Metal stands as your trusted partner in high-accuracy manufacturing. For over 15 years, we’ve collaborated with global clients across industries to deliver precision sheet metal parts and components that meet the most demanding specifications. Our commitment to excellence has made us the manufacturing partner of choice for leaders like ASML and Huawei, who rely on our capability to produce parts with exceptionally high dimensional and cosmetic requirements.

Our Manufacturing Excellence: The Vanmodel Advantage

Precision Sheet Metal Fabrication

At the heart of modern manufacturing, precision sheet metal fabrication plays a crucial role in producing everything from industrial machinery to consumer electronics . Our comprehensive approach ensures superior quality, cost-effectiveness, and the ability to produce complex designs that would be impossible with traditional metalworking techniques .

Our capabilities include:

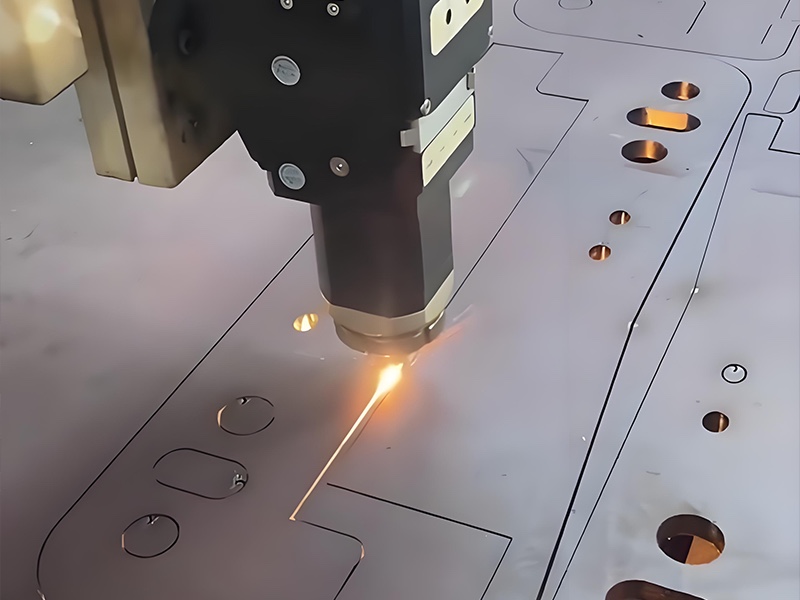

- Laser Cutting: Utilizing state-of-the-art equipment for clean, precise cuts with minimal material waste

- CNC Bending: Automated bending machines providing consistent and precise angles with high repeatability

- Complex Welding: Mastering laser, spot, MIG/MAG, and TIG welding for thin-gauge materials and complex geometries

- Surface Finishing: Comprehensive options including powder coating, electroplating, and specialized coatings

High-Speed Precision Stamping

Our advanced stamping capabilities set us apart in producing high-volume components with microscopic accuracy:

Key Services:

- Multi-Stage Progressive Dies: Expertise in designing and implementing complex die systems for continuous production

- Miniature Components: Specializing in parts down to 0.002″ thickness with tight tolerances

- High-Volume Production: Reliable annual production runs of 50,000-100,000+ units

- Material Versatility: Working with 50+ certified metal and plastic materials

Custom Stamping Die Design & Production

Our experienced mold engineers design high-performance, long-life dies that accelerate your time-to-market while maintaining exceptional quality standards. We combine CAD engineering with practical manufacturing knowledge to create tools that withstand millions of cycles without degradation.

Precision Solutions for Key Industries

Automotive Electronics

We manufacture critical components including engine brackets, sensor housings, connector terminals, and EV battery parts with focus on:

- Structural Integrity: Ensuring components meet rigorous automotive standards

- High-Volume Consistency: Maintaining precision across production runs of any size

- Compliance: Adhering to IATF 16949 standards for automotive quality management

Medical Devices

Our medical manufacturing capabilities include equipment enclosures, surgical instrument chassis, and diagnostic device mounts with emphasis on:

- Biocompatible Materials: Expertise with 316L stainless steel and other medical-grade materials

- Ultra-Clean Processes: Maintaining environments suitable for medical device production

- Regulatory Compliance: Meeting ISO 13485 standards for medical device manufacturing

Semiconductor Equipment

For the semiconductor industry, we produce chamber assemblies, wafer transfer modules, and sensor mounts with focus on:

- Contamination Control: Utilizing specially treated aluminum and other low-particulate materials

- Vacuum Compatibility: Engineering components for high-vacuum environments

- ESD Protection: Implementing proper grounding and material selection practices

Industrial & Consumer Applications

From server racks to smartphone structural frames, we deliver solutions balancing aesthetics, functionality, and manufacturability across industrial and consumer sectors.

Quality Assurance: The Foundation of Everything We Do

Certification & Compliance

Our quality management system forms the backbone of our manufacturing excellence:

- ISO 9001:2015 Certified: Ensuring systematic quality management practices

- IATF 16949 Compliance: Meeting rigorous automotive industry standards

- ISO 13485 Ready: Adhering to medical device manufacturing requirements

Advanced Metrology & Inspection

We invest in cutting-edge inspection technology to validate every dimension and surface:

- Coordinate Measuring Machines (CMM): For comprehensive dimensional analysis

- Video Measuring Machines (VMM): Providing precise optical measurements

- Surface Testers: Ensuring cosmetic and functional surface requirements

- Material Traceability: Complete documentation from raw material to finished part

Continuous Monitoring

Our real-time order tracking system and batch-level dimensional inspection reports provide unprecedented transparency throughout the manufacturing process, giving you peace of mind and ensuring on-time delivery.

Global Reach & Logistics

Strategically located in Guangdong, China, our 2,000㎡ modern manufacturing facility leverages the region’s manufacturing ecosystem while maintaining global standards of quality and precision. We support worldwide logistics through:

- Express Shipping: DHL and FedEx for urgent deliveries

- Air Freight: Efficient aerial transport for time-sensitive shipments

- Sea Shipping: Cost-effective container shipping for large volume orders

Partner with Vanmodel: Beyond Manufacturing

At Vanmodel, we see ourselves as more than just a manufacturer – we’re your strategic partner in product realization. From initial design consultation and material selection through precision machining and final surface finishing, we provide end-to-end manufacturing solutions that help bring your ideas to life efficiently and cost-effectively.

Our technical team brings 15 years of expertise to every project, ensuring design for manufacturability, optimal material selection, and the most efficient production approach for your specific requirements.

Experience the Vanmodel difference in your next project.

Contact us today to discuss your manufacturing needs and discover why industry leaders trust us with their most critical components.

Explore our capabilities at vanmodel-sheetmetal.com