How Precision Metal Molds Power Modern Manufacturing

Vanmodel | Engineering the Future of Precision Tooling

The Indispensable Role of Precision Molds in Modern Manufacturing

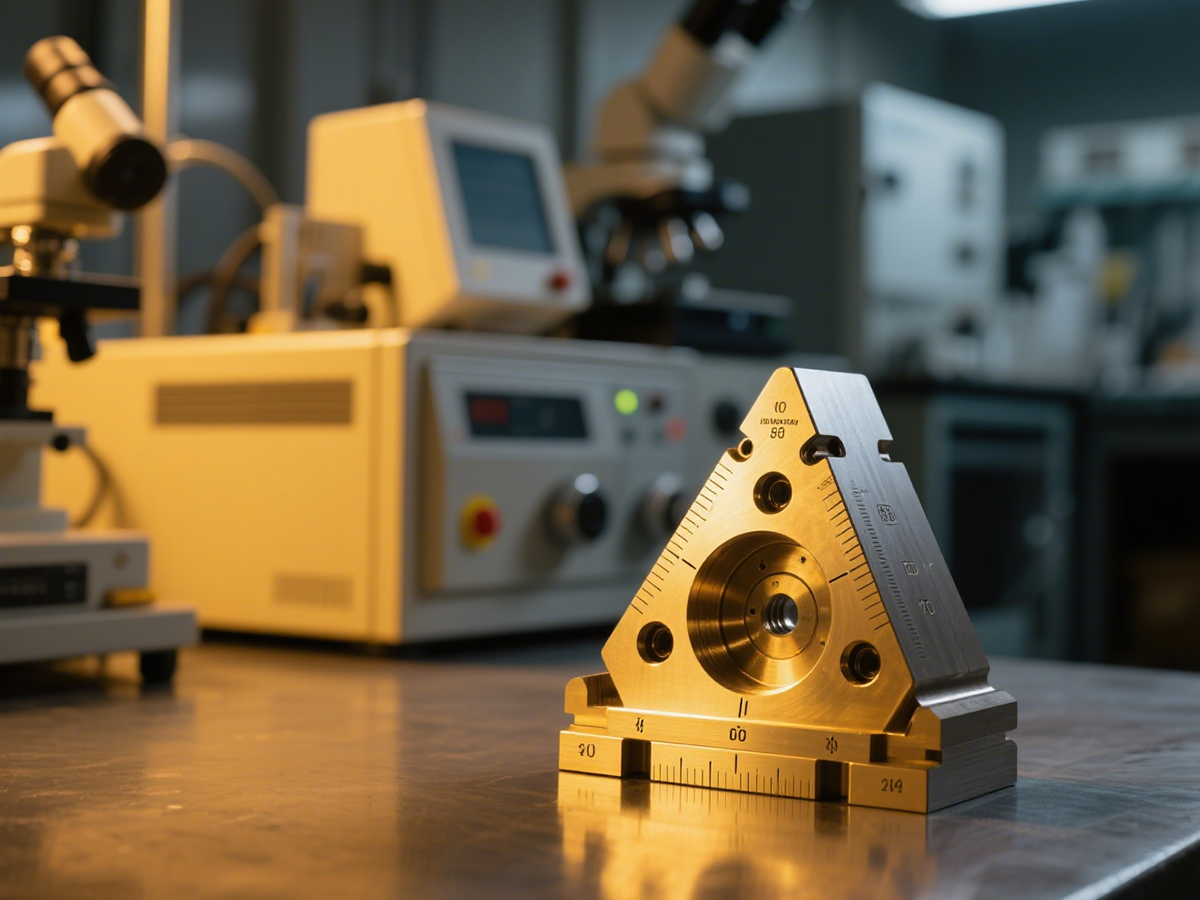

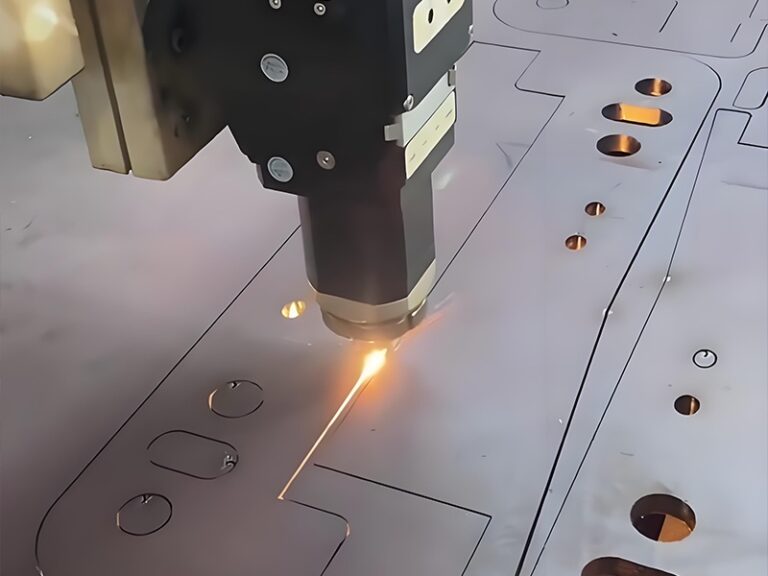

In today’s advanced manufacturing landscape, precision metal molds serve as the fundamental backbone of high-reliability component production across automotive, aerospace, electronics, and medical sectors. From intricate engine components to life-saving surgical instruments, these sophisticated tools enable mass production of complex geometries with microscopic accuracy. As an industry leader among moulding makers, Vanmodel continues to push the boundaries of what’s possible in precision tooling and industrial innovation.

Understanding Precision Metal Molds: Beyond Basic Tooling

A precision metal mold represents far more than just a manufacturing material in die casting, injection molding, and stamping processes. These highly specialized tools are engineered to produce metal workpieces with exceptional dimensional accuracy and repeatability. What sets precision molds apart is their ability to maintain tight tolerances while withstanding the rigorous demands of high-volume manufacturing environments.

Key Characteristics That Define Excellence:

Uncompromising Precision

- Tolerance capabilities reaching ±0.001mm for critical applications

- Advanced CAD/CAM integration ensuring perfect replication across production runs

- Digital twin technology for real-time performance monitoring and adjustment

Exceptional Durability

- Crafted from premium materials including H13 tool steel, carbide composites, and specialized alloys

- Engineered to withstand millions of cycles without degradation

- Advanced heat treatment processes enhancing wear resistance and longevity

Optimized Production Efficiency

- Reduced cycle times through innovative cooling channel design

- Automated systems enabling continuous operation with minimal intervention

- Smart mold technology with embedded sensors for proactive maintenance

The Tangible Benefits of Precision Mold Investment

Enhanced Product Quality Assurance

Precision molds consistently produce components with standardized dimensions and surface finishes, making them indispensable for industries where quality cannot be compromised. Whether manufacturing critical automotive safety components or medical devices requiring flawless performance, precision molds ensure every part meets the most stringent quality standards.

Accelerated Production Timelines

Modern precision molds enable manufacturers to produce large volumes of identical parts with unprecedented speed and consistency. Through optimized cycle times and reduced downtime, these advanced tooling solutions dramatically shorten time-to-market for new products while maintaining exceptional quality standards.

Long-Term Cost Efficiency

While precision molds require higher initial investment, their long-term economic benefits are substantial:

- Significant reduction in material waste through optimized design

- Minimal requirements for secondary finishing operations

- Extended service life reducing tooling replacement costs

- Lower per-part cost through high-volume efficiency

Critical Considerations for Mold Selection

Material Compatibility Analysis

Choosing the appropriate mold material requires careful consideration of multiple factors:

- Thermal properties for high-temperature applications

- Corrosion resistance for specific manufacturing environments

- Wear characteristics based on production volume requirements

- Compatibility with base materials being processed

Production Volume Optimization

Different manufacturing scenarios demand specific mold solutions:

- Aluminum or zinc alloys for prototype and low-volume production

- High-grade tool steels for mass production environments

- Specialty composites for abrasive or corrosive applications

- Modular designs for flexible manufacturing requirements

Complexity Management

Advanced precision molds excel in producing components with:

- Micro-features requiring exceptional detail resolution

- Complex geometries with tight tolerance requirements

- Multi-material compatibility for hybrid components

- Surface finish specifications down to mirror-quality levels

Strategic Investment Planning

When evaluating precision mold investments, consider:

- Total cost of ownership versus initial acquisition cost

- Return on investment through production efficiency gains

- Maintenance requirements and service life expectations

- Compatibility with existing and future manufacturing systems

Advanced Customization Capabilities

Modern precision metal molds can be extensively customized to meet specific manufacturing requirements, enabling production of highly specialized components for demanding applications. This flexibility is particularly valuable in industries such as aerospace and medical devices, where unique operational requirements often necessitate custom solutions.

Vanmodel’s Engineering Excellence: Setting New Standards

As a vertically integrated moulding maker, Vanmodel delivers unparalleled expertise through:

Certified Quality Systems

- IATF 16949 certification for automotive tooling

- ISO 13485 compliance for medical device manufacturing

- Comprehensive validation protocols for implant-grade components

Innovative Technology Integration

- AI-driven predictive maintenance systems

- Zero-downtime production monitoring

- Advanced simulation and modeling capabilities

- Real-time performance optimization

Industry-Specific Solutions

- Electric vehicle component tooling

- Robotic surgical instrument molds

- Aerospace-grade composite tooling

- Micro-electronics encapsulation systems

Conclusion: Precision as Your Competitive Advantage

In an increasingly competitive manufacturing landscape, precision metal molds continue to serve as the invisible engine powering technological advancement across every sector. From the rapid evolution of electric vehicles to breakthroughs in robotic surgery, these sophisticated tools remain at the forefront of industrial innovation.

At Vanmodel, we understand that precision tooling isn’t just about manufacturing components—it’s about enabling our clients to achieve their most ambitious engineering goals. Our commitment to excellence ensures that every mold we produce delivers not just immediate production benefits, but long-term strategic advantages.

Ready to Transform Your Manufacturing Capabilities?

[Explore Our Precision Mold Solutions]

[Request Technical Consultation]

[Download Our Capabilities Brochure]

Visit vanmodel-sheetmetal.com to discover how our precision engineering can elevate your next project.