Three Key Quality Control Points in Precise Metal Production

Industries widely use metal stamping as a process in manufacturing. It demands extremely high precision. As a core link in metal processing, metal stamping manufacturing directly determines the performance and safety of downstream products. Whether it is auto parts, electronic components or ev metal part stamping in new energy equipment, all rely on stable and reliable stamping process support. However, in actual metal stamping manufacturing processes, many enterprises often fall into “quality pitfalls” due to ignoring key quality control links. This leads to low product qualification rates, rising costs and even impacts on brand reputation. This article focuses on the core needs of precise metal production. It deeply analyzes three key quality control points in precision metal stamping and metal stamping manufacturing. It helps enterprises avoid production mistakes and improve product quality.

Raw Material Selection: Lay a Solid Quality Foundation for Precision Metal Stamping

Raw materials are the foundation of precision metal stamping. They are also the primary factor determining the final product quality. In metal stamping manufacturing, if the selected metal sheets have problems such as uneven thickness, excessive impurities or substandard mechanical properties, even the most precise subsequent processes cannot produce precision metal stamping parts that meet standards. Therefore, raw material selection must serve as the first line of defense in quality control. Enterprises must strictly implement the following measures:

first

Enterprises need to establish a sound supplier access mechanism. They should give priority to selecting qualified precision metal products inc or precision metal products private limited. This ensures that the purchased metal sheets meet industry standards. For example, stainless steel sheets used in custom metal stamping for high-precision applications need to have their tensile strength, elongation and other indicators tested. This avoids cracking during stamping due to insufficient material toughness.

Second

All batches of raw materials must undergo inspection before storage.Professionals use professional equipment to test the thickness deviation, surface flatness and chemical composition of the sheets. They firmly reject unqualified materials.

Third

Third, enterprises need to select metal materials reasonably according to the requirements of different stamped metal parts. For example, when producing precision components for the electronics industry, manufacturers should use copper alloy sheets with good conductivity and ductility. For structural parts in the automotive industry, they should prioritize high-strength steel. This ensures that raw materials are highly compatible with the process requirements of precision metal stamping.

In the long-term practice of metal stamping manufacturing, many enterprises choose low-quality raw materials to save costs. This leads to frequent product deformation, dimensional deviations and other problems in subsequent production. On the contrary, it increases rework costs and time costs. Therefore, attaching importance to raw material selection not only lays a solid quality foundation for precision metal stamping, but also reduces production risks from the source and improves overall production efficiency.

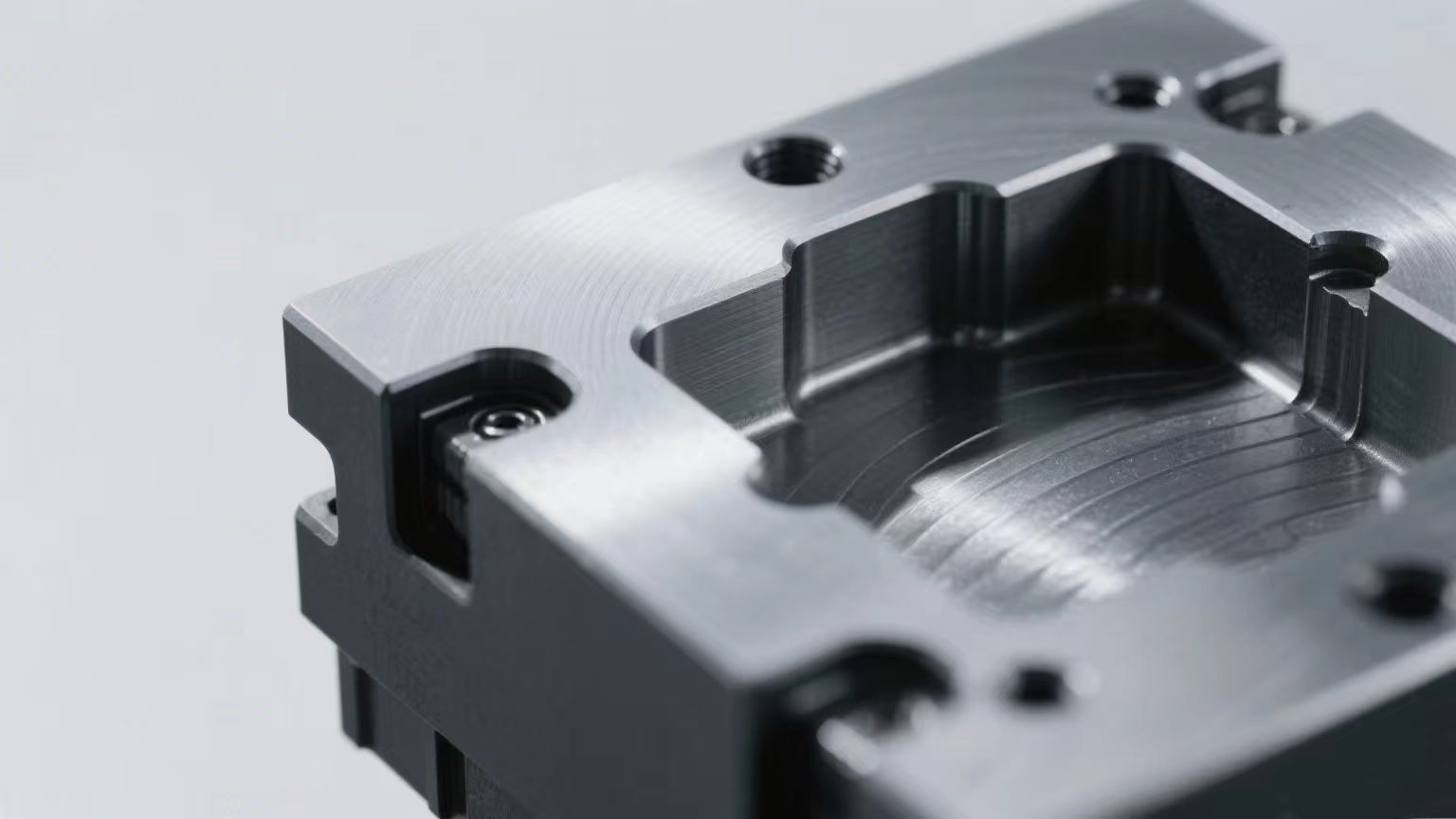

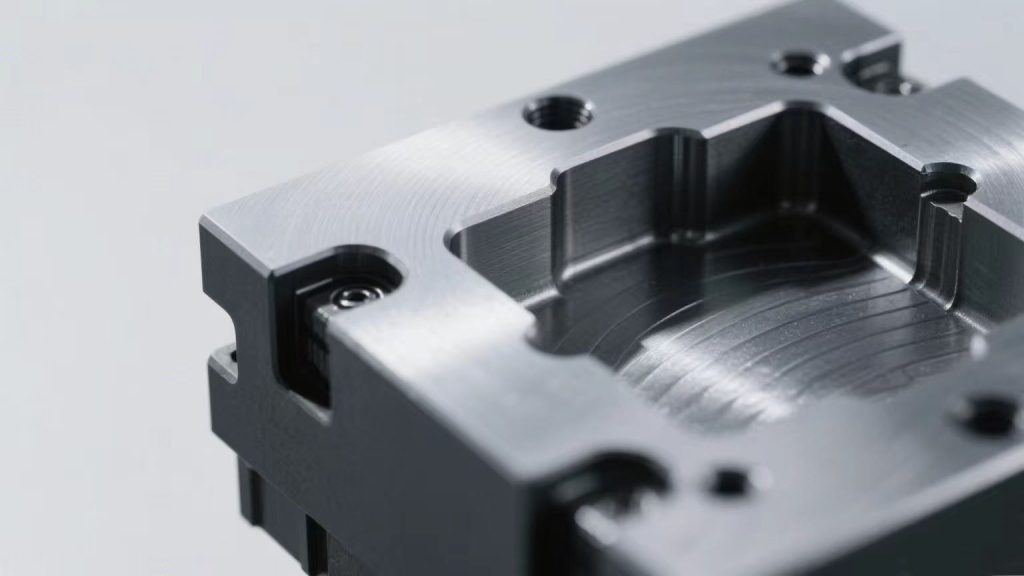

Mold Precision Control: Ensure the Core Link of Metal Stamping Manufacturing

Molds are core tools in metal stamping manufacturing. Their precision directly affects the product size and appearance quality of precision metal stamping. A set of high-precision molds can ensure stable output of standard-compliant precision metal stamping parts in each stamping operation. However, mold wear and reduced precision can cause a series of problems such as burrs and dimensional deviations in products. These become “invisible traps” in metal stamping manufacturing. Therefore, mold precision control must run through the entire life cycle of mold design, manufacturing, use and maintenance.

In the mold design stage, enterprises need to combine the specific needs of custom precision metal stamping services. They should use 3D modeling software for precise design. This ensures that the dimensional error of key parts such as mold cavities and cutting edges is controlled within 0.01mm. At the same time, according to the material and thickness of stamping metal parts, enterprises should design the mold gap reasonably. This avoids part scratching due to too small a gap or rough part edges due to too large a gap.

In the mold manufacturing process, enterprises need to rely on precision metal machining technology. They use precision equipment such as CNC machining centers and EDM forming for processing. This ensures that the machining precision of mold parts meets design requirements. In addition, after workers complete mold assembly, they need to conduct trial mold debugging. They should perform multiple trial stampings to test the product size and surface quality of precision metal stamping. They must correct deviated parts in a timely manner until the mold performance stabilizes.

In daily metal stamping manufacturing, mold maintenance is also crucial. Enterprises need to formulate regular maintenance plans. Before each production run, they should check the wear condition of mold cutting edges and the lubrication status of guiding mechanisms. During production, enterprises should conduct regular sampling inspections of the dimensions of stamped metal parts. Once workers find deviations, they immediately stop production for maintenance. For molds used for a long time, workers need to perform regular grinding and repair to ensure mold precision.This avoids the impact of mold aging on the quality stability of precision metal stamping. We can say that controlling mold precision well is a key measure to ensure continuous and stable production in metal stamping manufacturing and reduce quality problems.

In-Process Inspection: Real-Time Monitoring of Quality Stability in Precision Metal Stamping

In the continuous production process of metal stamping manufacturing, even if workers/operators select raw materials properly and control mold precision well, product quality may still deviate due to factors like equipment parameter fluctuations and improper operations.Therefore, in-process inspection serves as an important means for real-time monitoring of precision metal stamping quality. It must be detailed, timely and comprehensive. This ensures that problems are detected and solved early.

For in-process inspection, enterprises need to formulate a clear inspection plan. They should determine the inspection frequency, testing items and qualification standards. For example, for mass-produced precision metal stamping parts, inspectors should sample and inspect 50-100 pieces every hour. Testing items include dimensional accuracy, surface defects, geometric tolerances, etc. Precision measuring equipment such as calipers, micrometers and image measuring instruments are used. This ensures that products meet the requirements of custom precision metal stamping services.

At the same time, inspectors need to pay close attention to the operating status of stamping equipment. They check whether parameters such as press pressure, speed and stroke are stable. If operators find abnormal parameters, they should immediately notify equipment maintenance personnel to make adjustments. This avoids the production of batch unqualified products due to equipment problems.

In addition, for products with high precision requirements such as EV metal part stamping, manufacturers should adopt online testing technology. They use tools such as sensors and machine vision systems to monitor product quality in real time. This realizes fully automatic monitoring of the production process. Once unqualified products are detected, the system can automatically alarm and stop production. This effectively reduces the number of unqualified products and lowers production costs.

During the inspection process, detailed inspection records must be kept. These records include testing data, abnormal situations and handling results. They provide a basis for subsequent quality analysis and process optimization. Through strict in-process inspection, inspectors/quality control teams can eliminate quality hazards in metal stamping manufacturing in a timely manner.This ensures that the product quality of precision metal stamping remains stable at all times.

In the current increasingly competitive metal stamping manufacturing industry, good quality control in precise metal production is the key for enterprises to enhance their core competitiveness. Whether it is raw material selection, mold precision control or in-process inspection, every link cannot be ignored. By implementing these three key quality control points, enterprises can not only effectively avoid “quality pitfalls” in production, but also continuously produce high-quality precision metal stamping parts. This meets the market demand for custom metal stamping for high-precision applications.

If your enterprise encounters quality problems in metal stamping manufacturing or precision metal stamping, or needs professional custom precision metal stamping services, please contact vanmodel sheet metal immediately. With many years of experience in precision metal stamping, we are also equipped with advanced precision metal machining equipment and a professional quality control team. Beyond that, we can provide you with full-process solutions—covering product design, mold manufacturing, and even mass production—to further help your enterprise achieve high-quality development.

Good service

Want to fully implement the 3 key quality controls for precision metal stamping? Try The “Golden Combination”: Precision Sheet Metal Fabricators Paired with Stamping Services. If your enterprise encounters quality problems in metal stamping manufacturing or precision metal stamping…

https://vanmodel-sheetmetal.com/wp-admin/post.php?post=2941&action=edit

Read more: Three Key Quality Control Points in Precise Metal Production