How to Balance Functionality and Design in Custom Sheet Metal Fabrication?

In modern industrial and architectural fields, sheet metal processing is no longer just simple metal cutting and splicing. It has gradually become an important link connecting practical needs and aesthetic expression. From rust metal sheet walls that combine retro texture and protective performance to industrial enclosures with simple shapes that adapt to precision instruments, the birth of every high-quality sheet metal product relies on the precise balance between functionality and design. In this process, precision sheet metal fabrication and custom sheet metal enclosures, as core links, drive the continuous innovation of the industry with their flexible customization capabilities and strict precision control.

Demand Upgrade: Why Both Functionality and Design Are Indispensable?

With the increasing market demand for personalized and high-quality products, sheet metal products that only emphasize “usability” or “good looks” can hardly meet user expectations.

Application in Industrial Equipment Field

Take the industrial equipment field as an example. Equipment enclosures not only need basic functions such as waterproof, dustproof and impact resistance. They also need optimized appearance design according to the equipment installation scenario and operating habits. Overly bulky enclosures increase transportation and installation costs. Designs that are overly exaggerated but ignore protection may lead to equipment failures. At this time, custom sheet metal enclosures show their advantages. Enterprises can customize enclosures that meet protection standards and integrate into the overall space aesthetics according to equipment size and usage environment. For example, for medical equipment, manufacturers use smooth 304 sheet metal to make enclosures. This ensures the corrosion resistance and easy cleaning of the material (functionality) and enhances the professionalism of the medical space through simple line design (design sense).

Application in Architectural Decoration Field

Similarly, the popularity of rust metal sheet walls in the architectural decoration field confirms this trend. Such decorative walls use the unique texture of oxidized metal to create an industrial style atmosphere (design sense). They also select high-strength sheet metal materials to ensure the wall has sufficient wind resistance and weather resistance (functionality). To achieve the coexistence of this “appearance value” and “strength”, precision sheet metal fabrication is essential. Technicians perform precise cutting, bending and welding to make each metal plate splice perfectly. This ensures the structural stability of the wall and avoids damaging the overall visual effect due to dimensional errors.

Core Technology: How Precision Sheet Metal Fabrication Achieves Balance

Precision sheet metal fabrication, as the core technology of sheet metal processing, is the key to balancing functionality and design sense. Its “precision” not only reflects the strict control of dimensional errors (usually the precision can reach ±0.1mm) but also the optimization of the entire processing process to ensure each operation serves both functional requirements and design goals.

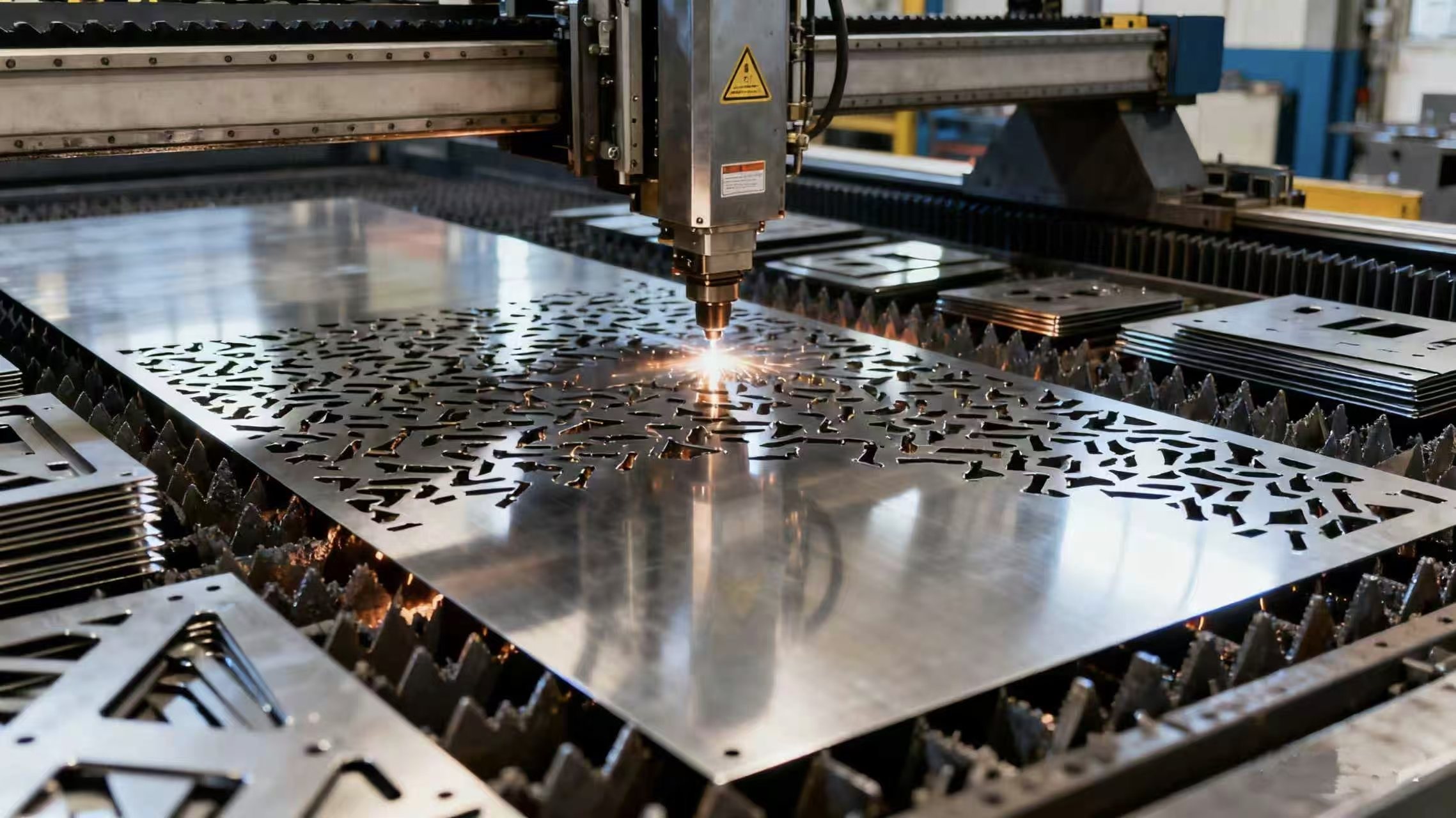

Precision Cutting Technology

In the processing process, sheet metal laser cutting and custom CNC metal cutting are important means to ensure precision. Compared with traditional cutting methods, laser cutting can realize more complex pattern cutting. Whether it is the heat dissipation hole design on the industrial enclosure or the hollow pattern on the decorative rust metal sheet wall, laser cutting can present them accurately. This not only meets the functional requirements of enclosure heat dissipation but also provides more possibilities for design innovation. At the same time, custom CNC metal cutting can mass-produce high-precision sheet metal parts with its automatic control capability. It avoids errors caused by manual operations and ensures the functional parameters and design details of each product are consistent.

Adaptation of Materials and Processes

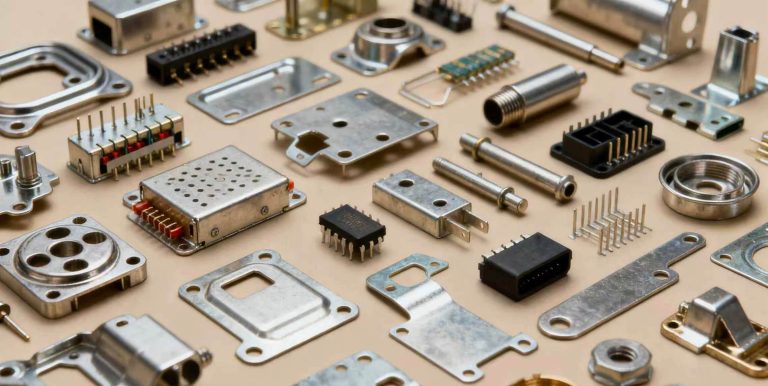

In addition, precision sheet metal fabrication focuses on the adaptation of materials and processes. Different application scenarios have great differences in the requirements of sheet metal materials. Industrial equipment enclosures may require the high strength and light weight of 6061 sheet metal. Food processing equipment needs food-grade stainless steel materials provided by stainless steel sheet metal suppliers. In the sheet metal workshop, technicians select the most suitable materials and surface treatment processes according to the product’s functional requirements (such as load-bearing, temperature resistance, corrosion resistance) and design style (such as matte, mirror, retro oxidation). For example, to customize a custom metal bracket that combines modern sense and durability, manufacturers first use aluminum sheet metal for CNC processing. Then they give the bracket various colors through anodizing treatment. This not only ensures the load-bearing performance of the bracket but also allows it to adapt to different decoration styles.

Scene Implementation: Diverse Applications and Balance Practice of Custom Sheet Metal Enclosures

As a typical product of custom sheet metal processing, custom sheet metal enclosures have vividly interpreted the way to balance functionality and design sense in applications in different industries. Whether it is industrial control boxes, communication equipment enclosures, or battery protection shells for new energy vehicles, each customized enclosure needs to go through the whole process of “demand analysis – design scheme – precision processing – inspection and acceptance”.

Application in Industrial Control Field

In the field of industrial control, a high-quality custom sheet metal enclosure first needs to meet the heat dissipation requirements of the equipment. Technicians will use custom cut metal technology to open heat dissipation holes of specific sizes on the enclosure. At the same time, they will optimize the hole layout using fluid mechanics principles to maximize heat dissipation efficiency (functionality). In terms of appearance design, simple linear bending will be adopted, with a unified color tone, so that the enclosure forms a visual coordination with other equipment in the workshop (design sense). Taking the control box of an automated production line as an example, its enclosure is made of precision sheet metal. The integrated design of heat dissipation holes and operation panel is realized through laser cut steel panels. This not only ensures the stable operation of the equipment, but also improves the convenience and aesthetics of operation.

Application in New Energy Field

The application of custom sheet metal enclosures in the new energy field is even more stringent. The battery shell not only needs to have high-strength impact resistance. It also needs to meet the requirements of fire prevention, waterproof and corrosion resistance. At the same time, it needs to be as lightweight as possible to improve vehicle endurance. To this end, manufacturers will select high-strength aluminum sheet metal. They will realize the thin-walled design of the shell through precision sheet metal fabrication technology – which not only reduces the weight (functionality). It also improves the aerodynamic performance and visual beauty of the vehicle through a smooth curved shape (design sense). In addition, precision welding technology will be used at the joints of the shell to ensure sealing performance. This avoids battery failures caused by water or dust, further enhancing the functionality of the product.

Choose a Reliable Partner: Vanmodel Sheet Metal Helps You Achieve Perfect Balance

To achieve the precise balance between functionality and design sense in custom sheet metal processing, it is crucial to choose a professional sheet metal processing enterprise. As a high-quality service provider focusing on precision sheet metal fabrication and custom sheet metal enclosures, Vanmodel Sheet Metal has many years of industry experience and advanced processing equipment. It can provide one-stop services from scheme design to finished product delivery for customers in different industries.

We have a professional sheet metal workshop, equipped with advanced sheet metal laser cutting equipment, jet sheet metal brake and sheet metal machinery. We can realize the whole process of precision processing from custom cut metals to sheet metal prototyping. Whether you need products of specific materials such as 304 sheet metal and 6061 sheet metal, or require complex-shaped rust metal sheet walls and custom metal plates, we can ensure that the products meet your functional requirements and present the ideal design effect with a strict quality control system and rich process experience.

In addition, we maintain long-term cooperation with high-quality aluminum sheet metal suppliers and stainless steel sheet metal suppliers to ensure the quality and supply stability of raw materials. For the needs of different customers, our technical team will provide one-on-one scheme optimization suggestions. For example, we recommend rust metal sheet wall processing schemes that are both beautiful and durable for architectural decoration customers. We design more adaptable custom sheet metal enclosures for industrial equipment customers, truly achieving “customization on demand and precise balance”.

If you are worried about balancing the functionality and design sense of custom sheet metal products, or need professional solutions from precision sheet metal fabrication companies, please contact Vanmodel Sheet Metal immediately. With professional technology, efficient service and high-quality products, we will help your project land. We will make every sheet metal product a perfect combination of practicality and aesthetics.

Precision Metal Stamping and Machining Synergy: Unlocking New Possibilities

https://vanmodel-sheetmetal.com/wp-admin/post.php?post=2970&action=edit

If you are worried about balancing the functionality and design sense of custom sheet metal products, or need professional solutions from precision sheet metal fabrication companies, please contact Vanmodel Sheet Metal immediately. With professional technology, efficient service and high-quality products, we will help your project land and make every sheet metal product a perfect combination of practicality and aesthetics.