Compatibility Logic of Steel and Aluminum in EV, Medical, and Electronics Industries

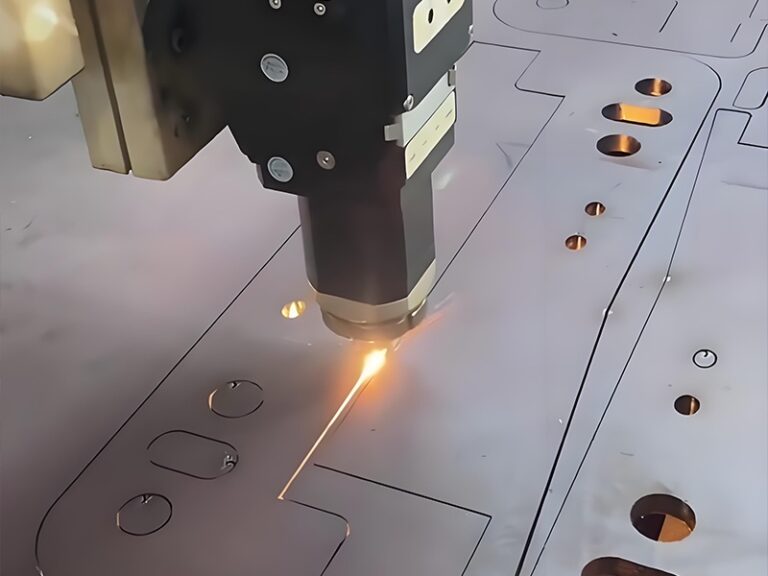

In the field of precision manufacturing, steel and aluminum serve as the two primary base materials. Consequently, the choice between them directly impacts product performance, cost, and market competitiveness. This is particularly critical in the EV, medical, and electronics industries, where high precision and reliability are mandatory. Precision metal stamping technologies, along with comprehensive custom precision metal stamping services, are essential to bridge the gap between material properties and industry needs. Since the core demands of these sectors vary significantly, a strategic approach is required. While steel offers high strength, aluminum provides light weight; thus, these advantages are complementary. Ultimately, transforming these material benefits into tangible product value remains a key challenge for manufacturers.

Compatibility Logic of Steel and Aluminum in EV, Medical, and Electronics Industries

The EV industry’s development hinges on two main goals: “range improvement” and “safety assurance.” This dual focus directly dictates how steel and aluminum are utilized. Aluminum, with a density merely one-third that of steel, is pivotal for body lightweighting. Specifically, reducing weight by 100kg can increase driving range by 5%-8%. However, aluminum’s inherent weakness compared to steel presents a challenge. To address this, precision metal stamping is employed to reinforce the material. By utilizing precise die design, the process ensures aluminum meets structural requirements without sacrificing its lightweight advantage.

For instance, EV battery pack housings rely on custom precision metal stamping services. These services produce aluminum alloy stampings that not only protect the battery but also reduce overall energy consumption. In contrast, for critical safety components like chassis and anti-collision beams, steel remains essential. High-strength steel, with a tensile strength exceeding 1500MPa, effectively absorbs crash energy to protect occupants. Forming these robust parts requires precision metal stamping. Cold stamping allows for complex one-time forming, which consequently reduces strength loss associated with welding.

Currently, most EV manufacturers adopt a “mixed scheme” combining an aluminum body with steel safety structures. Implementing this hybrid approach requires custom precision metal stamping services to customize processes for different components. This covers a full cycle—from material selection and die development to mass production—ensuring a seamless match. As highlighted in the article “Custom metal stamping for high-precision: Tackling the challenges in EV metal part stamping,” high-precision stamping is the core support for resolving material application conflicts in EVs.

Furthermore, in small components such as motor cores and connectors, precision metal stamping delivers extreme precision. These parts require tolerances within ±0.01mm. Steel, known for its dimensional stability, is the preferred material here. Custom precision metal stamping services provide tailored solutions, enabling efficient forming and precise cutting. This capability meets the strict operational needs of high-speed, low-loss EV motors. Simultaneously, ev metal parts stamping is a specialized field. As its technical standards continuously upgrade, the application boundaries of steel and aluminum in the EV industry continue to expand.

Medical Industry: Value of Custom Precision Metal Stamping Services under Aseptic and Corrosion-Resistant Needs

The medical industry prioritizes “biocompatibility,” “asepsis,” and “corrosion resistance.” These strict requirements lead to scenario-based selection of steel and aluminum. Stainless steel, a key branch of steel, contains high chromium (≥12%). This composition grants it excellent corrosion resistance, making it the mainstream choice for medical housings and surgical tools. During production, precision metal stamping plays a vital role. Its burr-free process prevents metal chip residue, thereby avoiding infection risks. Additionally, it ensures a smooth surface that facilitates disinfection.

However, for lightweight needs—such as portable ultrasound housings—aluminum proves useful due to its processing ease and light weight. Nevertheless, aluminum’s tendency to oxidize requires mitigation. To solve this, custom precision metal stamping services incorporate surface treatments like anodic oxidation. This creates a dense oxide film, enhancing both corrosion resistance and biocompatibility. For example, consider the flow control part of an infusion device. The aluminum alloy part, formed by precision metal stamping and treated post-production, maintains stable performance during long-term contact with liquid medicine. Consequently, it prevents harmful material precipitation.

Given that the medical industry has highly individualized needs, different equipment demands unique specifications. This is precisely where custom precision metal stamping services add immense value. They offer full-process customization, covering everything from sample development to mass production quality control. As noted in “How to Choose a Precision Sheet Metal Factory? Key Points Are Here,” medical stampings require unwavering process stability. The standardized production of precision metal stamping provides this guarantee. Moreover, precise metal production quality control is exceptionally strict. Each batch undergoes multiple inspections to ensure compliance with rigorous medical standards.

Electronics Industry: Precision Metal Stamping for Miniaturization and Conductivity

Driven by trends toward “miniaturization” and “high-density integration,” the electronics industry imposes extreme demands on metal parts. Specifically, it requires high dimensional accuracy and stability. In this context, steel and aluminum have distinct, specialized roles. Precision metal stamping serves as the core technical support. For shielding covers and heat sinks, steel is preferred due to its superior electromagnetic shielding and thermal conductivity. These miniature parts are often just a few millimeters in size. Therefore, stamping accuracy must reach the micron level. Using high-precision dies and CNC equipment, precision metal stamping forms complex structures to meet strict design standards.

In contrast, aluminum is selected for applications prioritizing conductivity and light weight, such as connector pins and circuit board heat sinks. Although aluminum is less conductive than copper, it is cheaper and lighter. Thus, it offers excellent cost performance for medium and low currents. To optimize these parts, custom precision metal stamping services customize processes like thinning drawing. This reduces thickness while maintaining stable conductivity. For instance, smartphone battery connector pins are formed from aluminum alloy via precision metal stamping. As a result, they fit into the phone’s narrow internal space while ensuring stable current transmission.

Because the electronics industry updates at a rapid pace—with product cycles often under a few months—custom precision metal stamping services must respond quickly. They need to rapidly develop dies, deliver samples on time, and switch to mass production efficiently. Professional services effectively shorten the R&D cycle. Furthermore, the article “Custom metal stamping for high-precision: Tackling the challenges in EV metal part stamping” emphasizes the need for flexibility. The modular production of precision metal stamping meets this demand perfectly. Additionally, combining precision metal machining with stamping processes aids complex structure forming. This synergy achieves a breakthrough from 2D to 3D forming capabilities.

Core Logic of Base Material Adaptation

In summary, the compatibility logic revolves around three interconnected elements: base material characteristics, industry needs, and process support. Steel’s strength and stability are vital for EV safety structures, medical corrosion-resistant parts, and electronic shielding. Conversely, aluminum’s light weight and processability suit EV bodies, medical portable devices, and electronic conductive parts. Precision metal stamping is the indispensable process that maximizes material performance. Meanwhile, custom precision metal stamping services integrate materials and needs through custom solutions.

In actual production, metal stamping manufacturers must establish comprehensive material databases. They must also align with industry standards to provide full-process services. This journey spans from material selection to process customization. Specifically, for EV collision safety, they recommend the appropriate steel grade and pair it with precision metal stamping. Similarly, for medical asepsis, they integrate anti-pollution design directly into the stamping process. Furthermore, combining precision metal fabrication with stamping expands application scenarios. Ultimately, this integration allows for the successful forming of more complex structures.

Conclusion: Choose a Professional Partner

Successfully adapting steel and aluminum requires a deep understanding of material properties. It also requires robust professional stamping support. The accuracy control of precision metal stamping, combined with the customization advantage of custom precision metal stamping services, is the core guarantee for solving application issues. Consequently, this approach improves product competitiveness. If you are seeking metal stamping solutions for EV, medical, or electronics products, please contact vanmodel sheet metal. We leverage a professional technical team and extensive industry experience. We provide full-process services, covering scheme design to mass production. Partner with us to maximize the value of steel and aluminum.