Advantages and Limitations of Aluminum in Precision Metal Stamping Parts

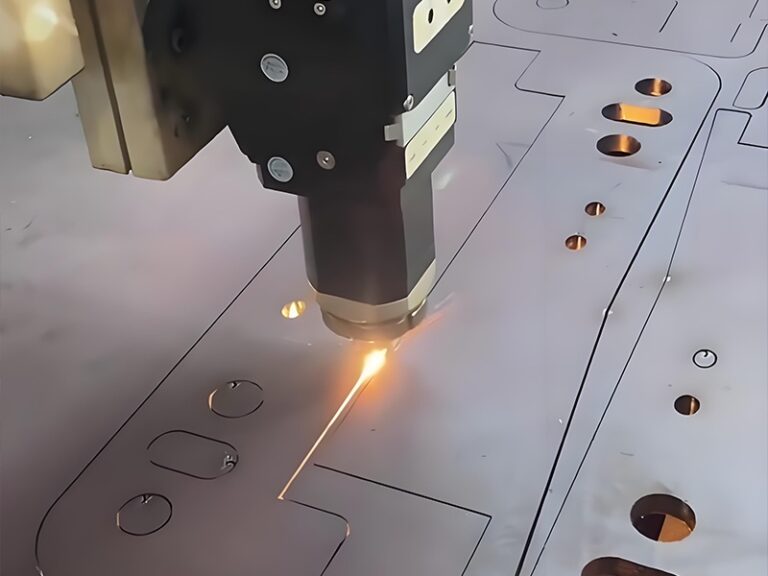

The precision metal stamping industry is developing rapidly. At this time, material selection directly determines the performance, cost and application scenarios of stamping parts. Fortunately, aluminum relies on its unique physical and chemical properties, and thus has occupied an increasingly important position in the production and manufacturing of precision metal stamping parts. Whether in the automotive, electronics, or new energy sectors, precision metal stamping parts made from aluminum are widely used. This article will deeply analyze the application advantages and limitations of aluminum in precision metal stamping, providing a reference for production decision-making in relevant enterprises.

I. Core Advantages of Aluminum for Precision Metal Stamping

Aluminum’s widespread application in the precision metal stamping field is closely linked to its multiple advantages. These strengths not only meet the stringent material requirements of precision stamping but also help metal stamping manufacturing enterprises reduce production costs and enhance product competitiveness.

1. Outstanding Lightweight Performance Meets Modern Industrial Needs

Aluminum has a density of only 2.7g/cm³, approximately one-third that of steel. This lightweight advantage is particularly crucial in the application of precision metal stamping parts. In the automotive manufacturing sector, with the popularization of new energy vehicles, the demand for lightweight EV metal parts stamping has become increasingly urgent. Body components, battery casings, and other precision metal stamping parts made by aluminum stamping can effectively reduce the overall vehicle weight and improve driving range.

In the electronic equipment field, products such as mobile phones and laptops have strict requirements for portability. Moreover, aluminum-based precision metal stamping parts—such as casings and internal brackets—ensure structural strength while reducing device weight. This not only enhances user experience but also lowers transportation costs for these lightweight components. In turn, this brings greater convenience to metal stamping manufacturers’ supply chain management.

2. Excellent Machinability Improves Stamping Efficiency and Precision

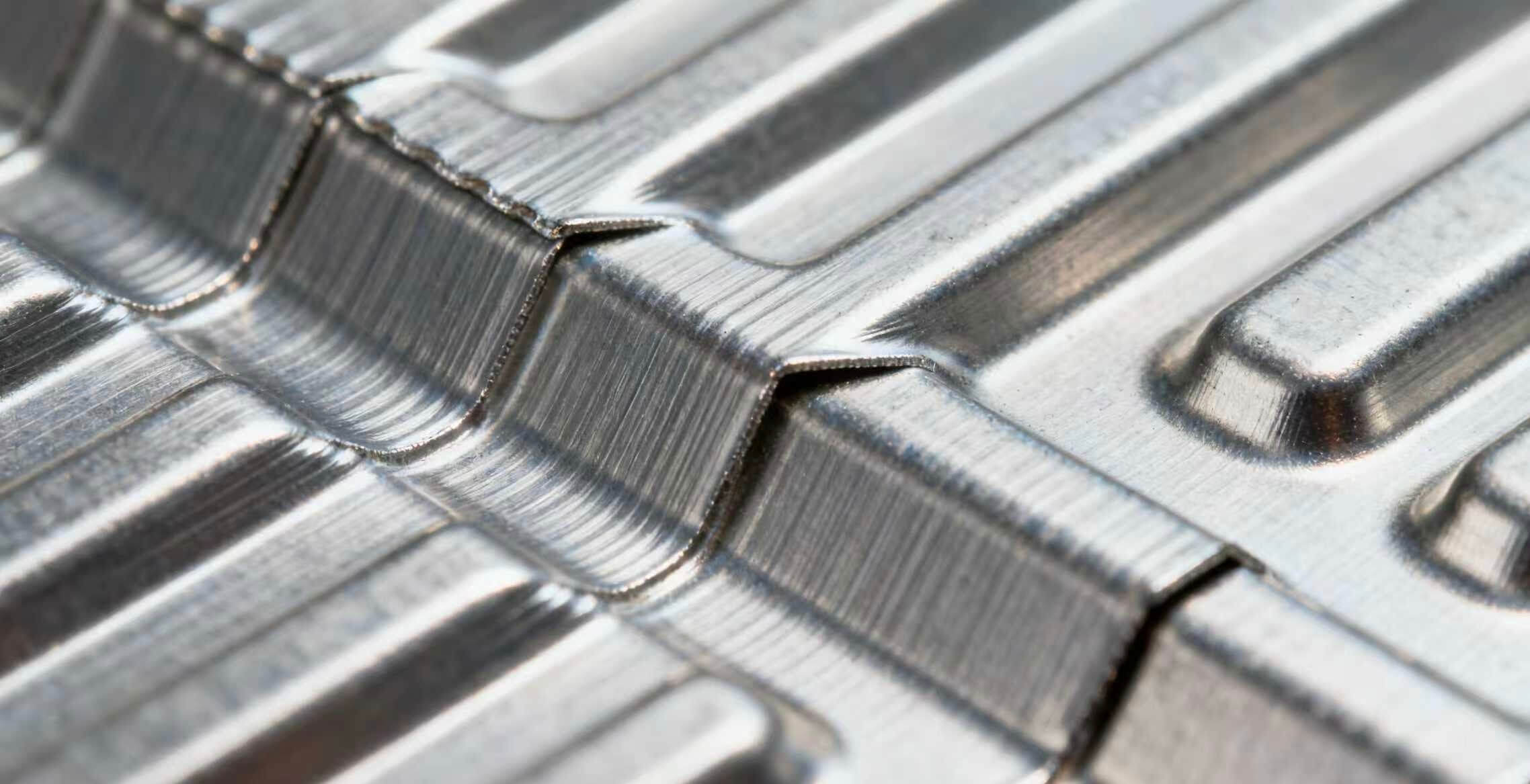

Aluminum boasts superior plasticity and ductility. During the precision metal stamping process, it can easily adapt to complex stamping procedures such as drawing, bending, and punching without being prone to defects like fractures and cracks. This excellent machinability enables aluminum to achieve precise forming, meeting the strict dimensional accuracy requirements of precision metal stamping parts. The dimensional tolerance of some high-precision aluminum stamping parts can be controlled within 0.01mm.

Meanwhile, aluminum features excellent surface quality. After stamping, aluminum parts require minimal subsequent grinding and polishing. They can directly proceed to the next production step, which effectively improves the production efficiency of metal stamping manufacturing. As mentioned in the article Custom metal stamping for high-precision: Tackling the challenges in EV metal part stamping, the machinability of high-quality materials is the foundation for ensuring the quality of high-precision stamping parts, and aluminum is undoubtedly one of the ideal choices in this field.

3. Corrosion Resistance, Thermal and Electrical Conductivity Expand Application Scenarios

Aluminum forms a dense oxide film in the air, which can effectively prevent further corrosion of the metal. Therefore, precision metal stamping parts made from aluminum have good corrosion resistance and can be applied in harsh environments such as humid, acidic, and alkaline conditions, including marine equipment and chemical instruments.

Furthermore, aluminum boasts excellent thermal and electrical conductivity, performing remarkably in precision metal stamping parts like electronic heat-dissipating components and conductive terminals. For instance, in LED lamp heat-dissipating structures, aluminum stamping parts quickly conduct heat away—extending the lamps’ service life. In circuit connections, aluminum conductive terminals ensure stable current transmission, meeting the core requirements of electronic device operation.

4. Significant Cost Advantages Reduce Enterprise Production Pressure

Compared with copper, stainless steel and other metals, aluminum is more affordable. What’s more, its sources are abundant. These advantages help metal stamping manufacturers cut raw material costs effectively. At the same time, aluminum processing consumes less energy. The stamping equipment required for precision metal stamping has lower power, which can further reduce the production energy consumption costs of enterprises. Many enterprises are engaged in the large-scale production of precision metal stamping parts. In this process, aluminum’s cost advantage can effectively enhance their products’ market competitiveness. In turn, this helps the enterprises gain a favorable position in fierce market competition.

II. Application Limitations of Aluminum in Precision Metal Stamping

Despite its many advantages, aluminum has certain drawbacks in some application scenarios due to its inherent properties, requiring metal stamping manufacturers to make reasonable selections based on actual needs.

Relatively Low Strength Restricts Application in High-Strength Scenarios

Compared with steel, aluminum has lower strength and hardness. Especially at room temperature, its tensile strength is only about half that of steel. This makes aluminum stamping parts less suitable for scenarios subject to heavy loads, impacts, or wear, such as automotive chassis load-bearing components and construction machinery core parts.

Although alloying treatment (adding elements like magnesium and silicon) can improve the strength of aluminum, this process will increase raw material costs and exert a certain impact on the machinability of aluminum. It requires custom precision metal stamping services enterprises to implement precise process control.

Poor High-Temperature Performance Makes It Unsuitable for High-Temperature Working Environments

Aluminum has a relatively low melting point of only 660℃. In high-temperature environments, its strength will drop sharply, and it may even soften or deform. Therefore, precision metal stamping parts made from aluminum are not applicable to high-temperature working scenarios such as engine exhaust pipes and boiler components. This limitation restricts the application of aluminum in some industrial fields, where heat-resistant metals such as heat-resistant steel need to be used as alternatives.

Fast Wear of Stamping Dies Increases Equipment Maintenance Costs

During the precision metal stamping process, the oxide film on the aluminum surface is prone to peeling off. The peeled oxide film will cause wear to the stamping dies, shortening their service life. Furthermore, aluminum has relatively high viscosity and tends to adhere to the die surface during stamping. This means dies require frequent lubrication and cleaning, which increases equipment maintenance costs and downtime. For metal stamping manufacturers, this also means investing more funds in die maintenance and replacement—ultimately adding a certain degree of production pressure.

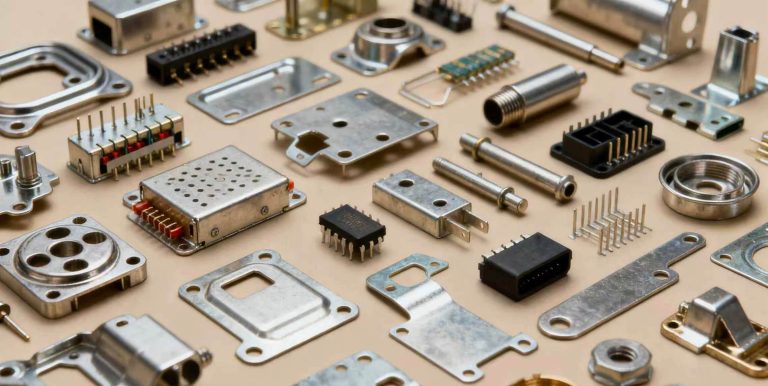

III. Typical Application Cases of Aluminum in Precision Metal Stamping

Despite certain limitations, aluminum has a wide range of application cases in precision metal stamping, covering multiple fields. In the new energy vehicle sector, EV metal parts stamping has a huge demand for aluminum. Precision metal stamping parts such as battery pack upper covers and motor end caps are all made of aluminum, which not only meets lightweight requirements but also ensures structural strength.

In the electronics field, custom precision metal stamping produces aluminum stamping parts like mobile phone middle frames and tablet casings. Thanks to their excellent appearance and machinability, these parts have become the preferred choice for many electronic enterprises. In the meantime, in the medical device field, some precision instruments’ casings and internal structural components are also made via aluminum stamping. By leveraging its corrosion resistance and lightweight advantages, this material helps improve the usability and portability of medical devices.

It is worth noting that the collaborative application of precision metal stamping and precision metal machining can further expand aluminum’s application scope. Precision Metal Stamping and Machining Synergy: Unlocking New Possibilities, combining stamping forming with subsequent machining can make up for aluminum’s shortcomings in precision and strength. In this way, it enables the production of precision components that meet high-end scenario requirements.

IV. Rational Material Selection to Optimize Precision Metal Stamping Solutions

Metal stamping manufacturers must consider application scenarios, performance requirements and cost budgets when selecting aluminum for precision stamping.

Specifically, prioritize aluminum for lightweight, corrosion-resistant, medium-to-low strength products like electronic components and general auto parts.

Conversely, choose steel or alloys for products needing high strength, high-temperature resistance and high wear resistance.

At the same time, enterprises should strengthen cooperation with custom precision metal stamping services providers. By optimizing stamping processes and improving die design, they can maximize the advantages of aluminum and avoid its limitations.

V. Conclusion

Aluminum has lightweight performance, excellent machinability and outstanding corrosion resistance. Furthermore, it also boasts good thermal and electrical conductivity, plus significant cost advantages. As a result, it shows great application value in precision metal stamping part production and has become one of the key raw materials in the precision metal stamping industry. Although it has limitations in strength, high-temperature performance, and die wear, the application scenarios of aluminum are still expanding through rational material selection, process optimization, and collaborative machining.

If you encounter material selection or process optimization problems in your precision metal stamping project, welcome to contact vanmodel sheet metal immediately. We will provide you with professional solutions and high-quality services.